Why Do Most Ships Use Diesel Engines?

Approximately 80% of global goods are transported by ship – things like grain, coal, food, clothing, and electronics. With over 15,500 containers loaded onto some of today's largest ships, to say these vessels need a potent engine is quite the understatement. You won't believe how big the world's largest piston engine is and how much power it can deliver (hint: it's found in a massive cargo ship).

These behemoths primarily use diesel engines due to several factors, such as efficiency, reliability, and power. To help cut transport costs, many big ships use heavy fuel oil, the cheapest option for shipping companies, with an average price per metric ton of $500 in 2024, per ShipUniverse.com. In addition, diesel fuel in general offers a higher energy density than other types, meaning a smaller amount will take your ship further.

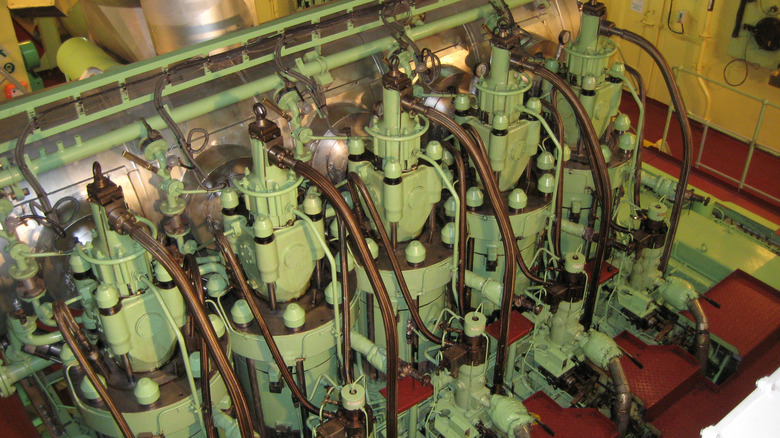

Also, to get these heavily loaded container ships pushing forward through the water, a massive amount of torque is required. Torque refers to twisting force, which in shipping translates to the energy used to turn the huge propellers under the water. Diesel engines produce more torque by incorporating a longer stroke (meaning the piston moves farther), higher compression, and turbocharging technology.

Many container ship diesel engines are two-stroke

Unlike a four-stroke engine, which consists of an intake, compression, combustion, and exhaust cycle, the two-stroke engine combines these steps into two piston strokes. (For those who are unfamiliar, here's what a "stroke" means on an engine.) Two-stroke engines offer some advantages over other variants, like an enhanced power-to-weight ratio, as they are lighter than a four-stroke. In shipping, weight is of foremost importance — transport companies can load more cargo using a two-stroke engine, without sacrificing performance power.

Unlike automobile powertrains, diesel ship engines like the MAN Diesel B&W 6S70MC-C hit their maximum at only 91 revolutions per minute. While this sounds extremely slow, remember that these maritime engines can reach four stories tall, and then imagine just how far the pistons are actually traveling. Diesel powerplants like the MAN Diesel B&W 6S70MC-C can easily achieve over 25,000 horsepower. (Although even with all that power, you might be surprised at how fast container ships travel and their top speeds.)

Some transport ships are moving away from heavy fuel oil

Heavy fuel oil is essentially what's left from crude oil after the processed bits have been pulled out. It's very thick, resembles tar, and as the name suggests, has some weight to it. Its peanut-butter-like viscosity requires it to be mixed with other fuels so it doesn't just sink to the bottom of the tank. While heavy fuel oil is cheap and energy-dense, it also has some disadvantages that have been shaking up the shipping industry in recent years.

The problem is that heavy fuel oil is toxic when it mixes with water or is subject to direct sunlight. This means that if there's an ocean spill, this sludgy substance can be devastating to both people and animals. It also puts out a large amount of air pollutants, like sulfur dioxide, that harm respiratory health. According to the International Council on Clean Transportation, heavy fuel oil's sulfur levels can be as much as 35,000 parts per million.

Alternative options like ultra-low-sulfur diesel fuel or very-low-sulfur fuel oil are now required in certain waters around the world, such as those around the U.S. and the North Sea bordering Europe. However, more emissions-friendly fuel costs more than heavy fuel oil, and considering a cargo ship can use over 84,000 gallons a day, the difference adds up quickly.