When Did Cummins Make Its First Engine? (And What Was It Used For?)

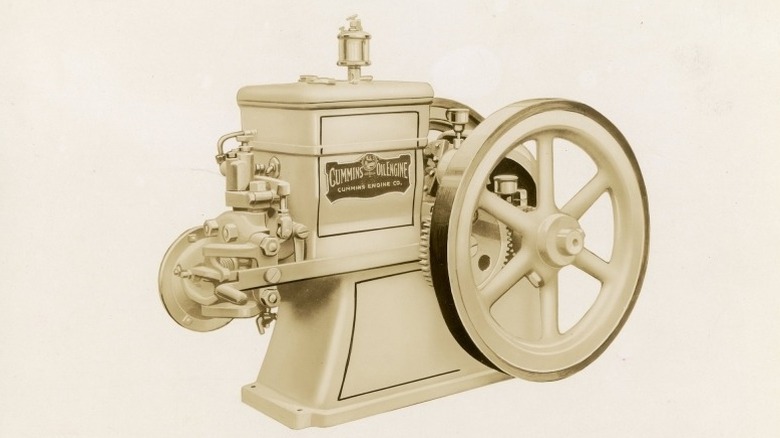

Cummins boasts a history that dates back over 100 years, including their diesel engines. The very first engine appeared way back in 1919, which just so happens to also be the same year that Clessie Cummins founded the company. Cummins launched the engine — a 6-horsepower stationary oil-burner — at the Indiana State Fair, hoping to catch the eye and open the wallets of farmers and other working-class professionals who were ready to embrace the future.

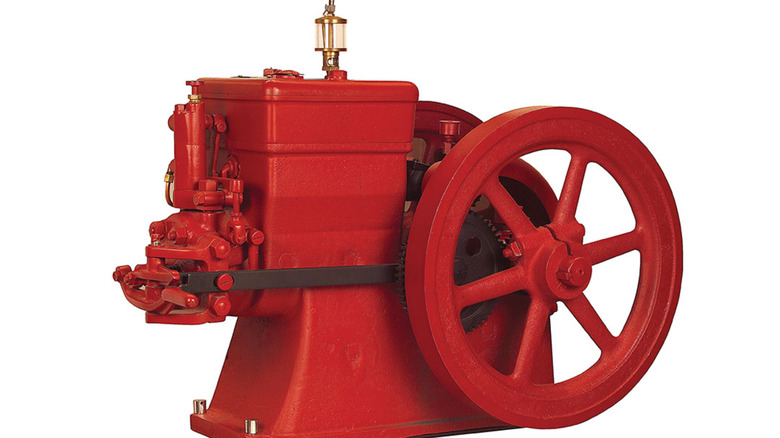

The engine was rugged and reliable, and hefty too, tipping the scales at an impressive 1,110 pounds. This 1919 engine is what's known as the first of the Hvid series, having been named after the gentleman who helped Cummins design the fuel system, Robert Hvid. The Hvid series would expand from here, to eventually include 1.5, 3, and 8-horsepower versions, before Cummins went on to produce other engines.

Back to the original 6-horsepower Hvid model, this engine would appeal hugely to farmers and other professionals, as they could simply attach a belt to the stationary engine which would then enable it to power water pumps, feed grinders, saws, and other such pieces of equipment. The Hvid series Cummins engine was easy to fuel too, being able to run on a variety of oils, such as vegetable, animal, or petroleum-based fuels, such as kerosene. Kerosene and diesel do have their differences, but you can still run most diesel engines on kerosene, especially older ones. This versatility was no doubt hugely attractive in areas where a stable fuel supply was yet to be established.

A closer look at the first Cummins engine

You may imagine that an engine from this era would now be simply reserved as a showpiece, or fancy paper weight, but Cummins would be keen to prove you wrong. The brand's heritage center tracked down an original Hvid engine (number 142) and restored it back to its former glory in 2017. The engine had been working hard for many decades prior to this in California.

In order to start the engine, you must hand-crank it, which is quite typical of engines from this era. There's also a compression lever to be released at the same time; just be sure to keep your hand well out of the way, and to let go at the right time; hand-cranking an antique engine genuinely could break your arm. After all of these years, the engine still bursts into life, and thumps away at a smooth 520 rpm. One of the great attractions to an engine like this is that you can see the connecting rod, the flywheel, and the fuel pump — almost every working part is visible without removing a single bolt.

It might be simple and archaic now, but it's important to remember that this is where it all began for Cummins — a 6-horsepower oil-burner. From here, Cummins has developed engines which power everything from semi-trucks and pickup trucks through to huge industrial machines, and even ships.