Who Makes Cosworth Engines And Where Are They Built?

In 1958, Cosworth was started by two young engineers who had a dream. Initially, Cosworth began its journey in the United Kingdom. After a two decades, the company was sold to another British engineering firm, the United Engineering Industries (UEI) in 1980. Another few years later, the company was sold to Carlton Communications, which opted to offer it for sale with less than a decade of ownership. While the Cosworth was sold to Vickers in 1990, it only took less eight years for it to change hands once again.

By 1999, portions of Vickers had been acquired by other British firms, such as Rolls-Royce and BAE Systems. However, right before this happened, Vickers sold Cosworth to Audi for $192.3 million in 1998. Not to mention, in a shocking turn of events, Audi almost immediately sealed the deal to offload the Cosworth racing division to Ford as well, effectively splitting the company.

In 2004, Ford sold the Cosworth F1 business to the racing magnates behind the Champ Car World Series, Kevin Kalkhoven and Gerald Forsythe. In the same year, Audi also proceeded to sell the rest of the company to the German automotive manufacturer, MAHLE, which eventually re-named the Cosworth technology division to MAHLE Powertrain. As of April 2024, Cosworth racing is owned by CGH (Isle of Man) Holdings Ltd and Indeck-Cosworth LLC. But, are they still built in the same factories that they were when the company first began?

Where are Cosworth engines made?

In it early days, Cosworth Engineering had its origins in London. However, the founders moved their operations to Northampton to be closer to their suppliers and to be closed to their suppliers in 1964. While their early goal was to build engines for the Formula 3 series, it didn't take long for them to become leaders in the Formula 1 space as well. Just three years later, Cosworth launched the Double Four Valve (DFV) engine in 1967. The V8 engine, which is part of our list of iconic game-changing engines that first appeared on Lotus cars during the Dutch Grand Prix. Starting from 1968, the renowned Cosworth V8 engine had stolen all the championship podiums for six years straight. By 1975, Cosworth landed in the United States with the turbocharged DFX, wherein it blew its competition out of the water at the Indy 500.

Despite all the changes in ownership, Cosworth has retained its primary manufacturing facilities in their Northampton base. In 2013, Production Engineering Solutions Media reported Cosworth's plan to build a world class 50,000 ft factory. As of 2024, Cosworth Northampton still prides itself as being a state of the art manufacturing center. In the years that followed, Cosworth also opened manufacturing plants in Indianapolis, Mooresville, and North Carolina. In 2018, the company opened its fourth American facility in Detroit, as well as its North American headquarters.

Cosworth's history of innovation

Founded by Mike Costin and Keith Duckworth, the word "Cosworth" is actually a combination of both of the founders' names. At the time, they were only 29 and 25 years old, respectively. However, their youth didn't stand in the way of building a company that would produce some of the world's most groundbreaking engines.

For more than 65 years, Cosworth has manufactured several remarkable engines that have graced everything from Formula 1 cars to insanely powerful commercial vehicles. But, while we know that Cosworth started with humble beginnings, it's definitely grown bigger in ways that its founders could have never dreamed about. Although its history is firmly rooted in the United Kingdom, its impact has been felt globally, including its production facilities and through its various partnerships with American automotive manufacturers, such as Ford and General Motors.

Apart from internal combustion engines, Cosworth also applies it innovation principles and engineering specialty to hybrid solutions, powertrain assembly, and high performance batteries. Known for their high-performance offerings, Cosworth engines have been a staple in motorsports for decades, as well as a favorite collaborator of premium vehicle manufacturers who are looking for a lot of power, like Bugatti and Aston Martin.

Knowing the global nature of how vehicle companies source their engines, one might wonder if it still matters where Cosworth engines are made. However, here are few surprising reasons why it does.

Why does it matter where Cosworth engines are made?

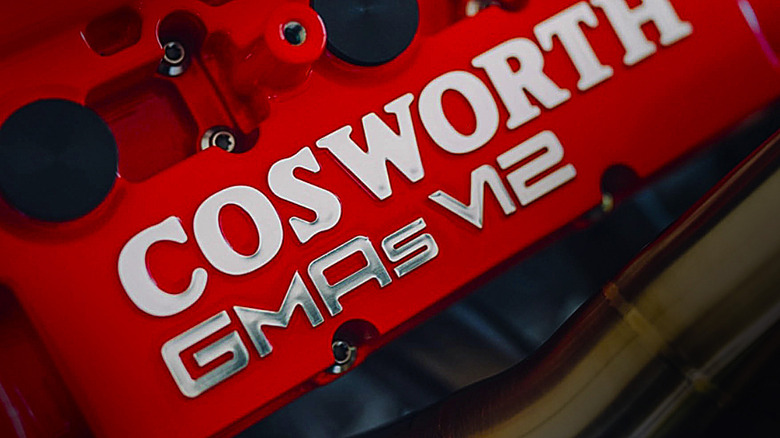

Aside from manufacturing, Cosworth still maintains its head office in Northampton to this day. Because of this, it's unsurprising that it continues to have strong relationships with several British manufacturers. In recent times, Cosworth has produced several bespoke engines during its run from Lotus, Gordon Murray, to Aston Martin. For example, McLaren's Gordon Murray worked with Cosworth to produce the powerful V12 for the Gordon Murray Automotive (GMA) T.50, which was designed to generate up to 654 hp, in 2020.

Speaking of V12, Cosworth also developed the RA engine for the renowned supercar Aston Martin Valkyrie. Considered one of the best engines ever made, the Cosworth RA V12 can reach an ungodly 1,160 hp when used in tandem with the KERS system, according to Car and Driver. Although not British, we also can't forget the Bugatti Tourbillon V16, which under the right conditions can even go as hard as 1,800 hp.

It's also important to note that because Cosworth manufactures engines for different military units in the EU and the United States, the stability of its supply chain can impact national security. In recent times, Cosworth engines have been used in everything from drones to hybrid military vehicles.