What Does OHV Stand For In Engines?

The internal combustion engine, despite being a century-and-a-half old, is still an impressive marvel of engineering. There are several variations of engine design that have been experimented with over the years, such as the Knight Sleeve Valve engine, but those who aren't as familiar with engines may not understand a lot of the terminology such as what OHV stands for and how it works, but this article aims to change that.

An engine can generate power through a process of mixing air and fuel within a cylinder, creating consistent but carefully measured mini-explosions. These small reactive blasts force the pistons, located inside the cylinder, to move up and down. The pistons are connected to the crankshaft, and this is what transforms the up and down energy into a rotational one, directing power to your vehicle's wheels. This example is the most common type of engine, but there are plenty of other weird engines used in production cars.

One of the critical parts of an engine that enables the creation of energy is the valvetrain. The valvetrain is the mechanism that controls the intake valve, which lets the oxygen and fuel into the cylinder, and the exhaust valve, which releases gas out of the cylinder. There are several types of valvetrains, but one common design is the OHV or overhead valve. Overhead valve configurations offer some advantages over other designs, such as making great low-end torque; however, the more straightforward design of OHVs limits its abilities at higher RPM ranges.

OHV: How it works

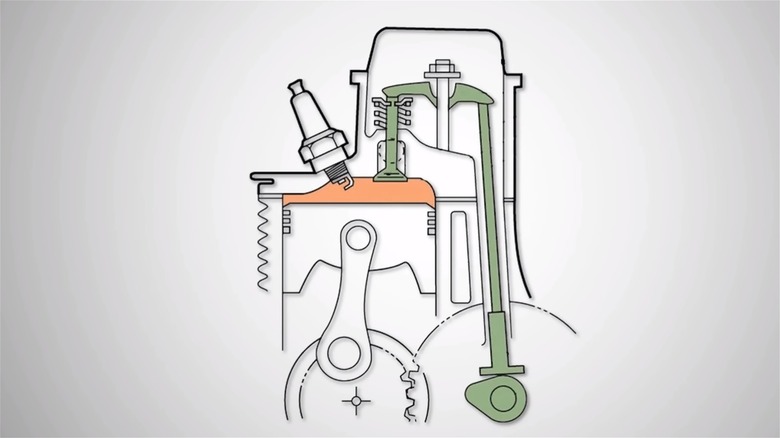

An overhead valve design uses a pushrod, rocker arm, and spring to control the movement of the valve. First the camshaft, which is a long rotational piece within the engine, features raised sections that move the pushrod up as the camshaft turns, but only at specifically timed moments. For simplicity, imagine the camshaft from the side view is shaped like a teardrop, and as it turns, the pushrod rides the outline of that shape causing it to go up and down.

When the pushrod goes up, the rocker arm, which is attached to the top of the pushrod, moves in a seesaw like motion. While one end of the rocker arm goes up along with the pushrod, the other end moves down and pushes the valve downward. The valve then moves into the cylinder creating an opening. Then, once the camshaft rotates further and the pushrod drops back down, the rocker arm seesaw's the other way pulling the valve up and closing the opening to the cylinder.

Since there is an intake valve and exhaust valve, there are four stages of this process with each valve opening and closing. This basic sequence is described as the four strokes that make up a four-stroke engine.

OHV: Pros and cons

There are some advantages of the overhead valve configuration, although it's seen in fewer engines nowadays. First, OHV is a design that can produce more power and torque, but only at lower speeds. Horsepower is different from torque and it's important to understand the contrast when comparing valvetrain systems.

Mechanic.com.au says that, due to its design, an OHV "accelerates the airflow through the intake runner, much like a narrow spot in an otherwise wide riverbed accelerates the river's rate of flow through the narrow spot." It's for this reason you'll find OHV in some full-size trucks. Unfortunately, this power doesn't hold up at higher speeds and other valvetrain configurations become superior.

OHVs also have a simpler design and are less expensive to build but can't keep up with the DOHC's (dual overhead camshaft) more complex timing at higher RPMs. In basic terms, valve timing is crucial for determining engine performance, and newer valvetrain systems are much more precise at controlling valves when the engine is revving closer to redline.