Here's How K-MAX Helicopters' Intermeshing Rotors Work

Historical references to spinning flying machines go back hundreds of years, with evidence like the 12th-century Chinese twirling kite and Leonardo da Vinci's bizarre airscrew contraption of 1483. Inventors tried multiple configurations before Germany reached that milestone with the Focke Achgelis Fa 61 in 1936.

Following the success of that first helicopter, aviation engineers continued to innovate, resulting in six unique rotor designs. However, not every configuration was successful, as evidenced by one of the weirdest assault vehicles the U.S. Army ever conceived: the Convair Model 49. Most often, you'll see helicopters with one main rotor and a single tail fan. However, one Bell helicopter has four small tail fans instead of one big rotor.

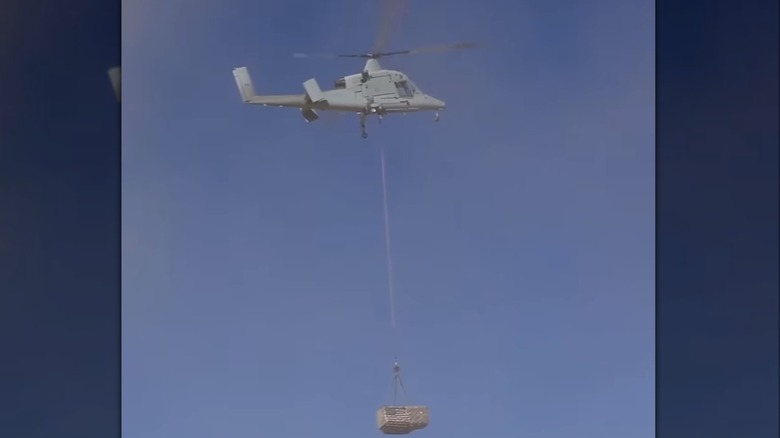

One of the more interesting rotor systems, however, is an intermeshing or synchropter configuration. You can observe this design on K-MAX helicopters, developed by Kaman Aerospace Company. Instead of just one main rotor, there are two, and they spin opposite each other to create lift for K-MAX helicopters.

But how does this system work exactly? What prevents the rotor blades from running into each other, and what advantages does this design offer?

Two rotors just feet apart?

When looking at a machine like the K-MAX K-1200, you might do a double take as it has two large spinning rotors right next to each other. The design looks strange and dangerous even, as the revolution per minute (RPM) of an average large helicopter is around 230, according to Radiant Helicopter Tour.

Fortunately, the blades are connected through central gears that keep them synched, so the overlapping blades don't make contact during each revolution. The easiest example of this type of synchronous design is found in your kitchen in the form of a hand mixer. When two beater attachments are secured into the mixer, look closely; you'll notice the beaters intermesh but never collide. Although spinning close and appearing to be independent, both beaters are connected.

In addition to being synchronized, the rotors don't collide because of the particular way they're oriented, which is slightly outward. According to the International Research Journal of Modernization in Engineering Technology and Science, "To ensure that the rotors do not collide, the swash plates and complex linkage gearboxes play the major role by controlling the blade pitch for each rotor and by providing them different pitch angles depending upon the forward speed, yaw, and roll control."

What are the benefits of intermeshing rotors?

While the design is more complex than other configurations like the single rotor, and they aren't as common, there are some significant upsides to the synchropter. Typically, a tail fan is required to counteract the force of the main rotor and prevent the helicopter's body from spinning. However, with K-MAX, the intermeshing rotors spin opposite each other, creating a balance without needing a tail rotor. Removing the spinning tail fan helps enhance efficiency and eliminates the energy requirements for the tail components found in other configurations.

Another positive is the amount of weight the K-MAX synchropter design can steadily hoist. The K-1200 FireMAX has been recorded supporting up to nearly 6,000 pounds. The combination of two large rotors provides not only the lifting ability for sizeable cargo but the stability to maintain control of the load. While 6,000 pounds is impressive for this mid-size aircraft, it can't hold a candle to the largest helicopter ever built could handle around 17,000 pounds.