5 Different Types Of Wood Routers (And Which Kind You Need For Your Project)

For woodworkers, carpenters, and hobbyists, a router is a handy tool for molding wood into specific shapes. Consisting of a motor that spins a bit, you can shave off precise pieces of wood, creating a more professional appearance. For example, notice the nice and clean bevel around any of your wood picture frames, and you can see the advantage of using a router.

There isn't just one type of router, but rather variations of the tool that serve different purposes during projects. These routers range in size from handheld to the more robust table-mounted variety, and each offers advantages and disadvantages.

To understand which router suits your project, compare the different types and consider which one might serve you best. Finding the right tool for the job makes the work more manageable and the result more impressive. Wood routers are just one of the cool tools you didn't know you wanted until now.

A trim router

A trim router with a one-horsepower or lower motor is the smallest and least powerful of the bunch. However, don't let its compact size fool you, as it's fantastic when you need the ability to maneuver around awkward sections of your project.

Shaping edges and working with smaller pieces of wood are ideal with the trim router as it is lighter than other options. In addition, due to the less powerful motor, you can purchase cordless trim routers, making the job easier without requiring an extension cord or outlet.

According to Family Handyman, a trim router is ideal on materials like laminate, so it may not fare as well against a hardwood like White Oak, Teak, or Ash. Rockler explains that depending on your cutting depth, a more powerful option may work better, especially if you're attempting deep mortise cuts. If you proceed with a compact router on a more challenging project, it can take longer and stress the motor, reducing the tool's lifespan.

A fixed-base router

A fixed-base router offers more power and versatility over the smaller and weaker trim router. With motors featuring over three horsepower, you can carve deeper grooves into wood and don't need to shy away from tougher materials. One of your first projects could be creating easy DIY storage options to help organize your tools.

This tool requires you to set and lock the depth before powering on (hence the name fixed-base) and doesn't allow you to alter your cutting pattern during operation. The fixed-base router is an excellent choice as it can take on smaller tasks suited for the trim router, such as edge profiling laminate. Still, it is capable of more demanding applications with its enhanced power.

Also, since the depth is locked during use, this router is easier to operate and less expensive than many other options. But remember that fixed-base routers don't offer built-in guides and work best at creating a consistent and contoured edge. If you plan on creating more complex decorative designs in your wood, the fixed-base router will limit your options.

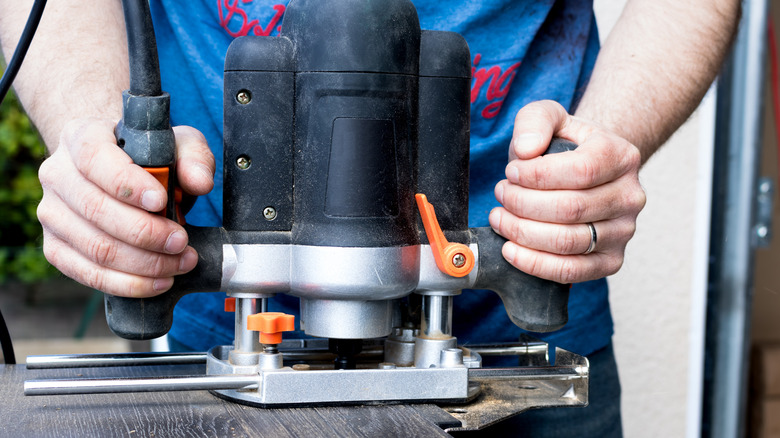

A plunge router

While the fixed-base router is more often seen in workshops, the similar plunge router, while more expensive, offers additional advantages. With a comparable motor to the fixed base, the plunge router is optimal when depth changes frequently during operation. For example, during furniture construction, experts often use mortise cuts, which require several passes to complete, with each cut going deeper. Where a fixed-base router would need to be powered down and adjusted for every pass, a plunge router can be freely raised or lowered while operating.

With a plunge router, you can adjust the maximum depth of the bit, but you must grab the side handles and push down to begin your cut. The vertical control of the router can be more physically demanding and require more precise movements. Those new to routers might find the tool's range of motion and opportunity for mistakes intimidating.

Even those with experience using this tool can still make errors if their project requires accuracy. The plunge router is a tool that offers greater freedom but requires finesse to operate; otherwise, it could cost you time and materials.

A fixed-based and plunge router combination

There are units available that combine the fixed-base and plunge router, allowing you to experience the advantages of both. The combo router usually comes with multiple bases, so you can swap out which type you need depending on the project.

This type of router is an excellent compromise for woodworkers who are still deciding which type to buy and beginners who may use the plunge router after gaining more experience. Other versions of the combination router don't offer multiple bases but instead require you to remove specific components like the springs to convert the unit. For example, if the tool is set up as a plunge router, removing the spring-loaded mechanism converts it to a fixed-base unit.

While having both a fixed and plunge router is handy, it can also pose some safety risks worth considering. To avoid mistakes and injury, you will want to ensure you have the intended base installed on the combination unit before cutting. Also, remember that the combination units will be heavier and generally cost more.

A router table

A router table is ideal for many applications because it's stationary and removes errors you could introduce while holding the tool. You can rely on a stable, flat surface and hold the material instead of the router for precise results. You can purchase different router tables, such as smaller benchtops and larger free-standing tables.

However, a router table doesn't come equipped with a router, and you will need to verify which makes and models of router fit the table you intend to purchase. Many fixed-based and plunge routers easily attach to a component of the table called the insert plate. Some insert plates offer convenient mounting options with pre-drilled holes that fit the most popular router models. In contrast, other table manufacturers allow you to drill your own holes or order alternate plates to accommodate your specific router.

You can also incorporate several router table accessories that attach to channels built into the unit for more precision. With special guards available, you can shape curved wood and use sleds for cross-cutting long pieces width-wise.

The disadvantage of a router table is the steep jump in cost when compared to other options like the fixed-based or trim router. If you aren't sure how much you'll use a router, you should hold off on purchasing a router table. On the other hand, if you see a lot of woodworking projects in your future, a router table might be a good investment.