Why Bacteria May Be A Key Part Of The EV Revolution

Despite numerous advances in electric vehicle (EV) battery technology, it's still a massive point of contention on an EV's actual carbon footprint. Additionally, batteries also fulfill one-half of the equation when it comes to the pain point of EV charging and affect range anxiety, one of the key limitations many existing EV owners have to deal with.

From hybrids to hydrogen-powered engines, it's no wonder that scientists have been scrambling for new ways to improve eco-friendly engine designs, especially batteries. Unexpectedly, a recent discovery may have just revealed a link between bacteria and the future of EV technology.

In November 2023, the Institution of Mechanical Engineers shared how a team of University of Edinburgh sustainable biotechnology scientists, led by Professor Louise Horsfall, are exploring the concept of using engineered bacteria to recover valuable metals from lithium-ion EV batteries.

This bio-based recycling process shares that bioengineered bacteria from the Edinburgh Genome Foundry are added into a fermenter to battery leachate to produce a natural biological reaction. Afterward, it says that the solution will produce nano-sized particles of metal compounds, which can be filtered out and recovered.

As of writing, the researchers are still undertaking tests on a previously used Nissan Leaf EV battery. If successful, here's what their discovery could mean for the EV industry as a whole.

How battery recycling can change the future of EVs

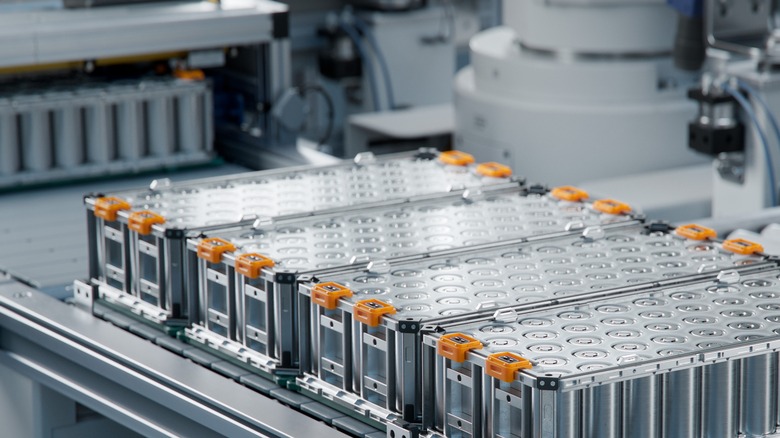

According to EPEC, lithium-ion is the most expensive type of battery chemistry to manufacture. Despite this, lithium-ion is still the primary type of battery used for electric vehicles. The Clean Energy Institute shares that lithium-ion batteries hold the highest potential for electric vehicles due to their high energy density and relatively long lifespans.

In 2016, an Argonne National Laboratory study claimed that EV battery manufacturing and end-of-life processes have a higher carbon footprint than their traditional gas counterparts. Through efficient recycling of rare metals, EV manufacturers can close the loop between both, making it the last piece of the EV sustainability puzzle.

In recent times, there have been other breakthroughs in the EV battery recycling space. However, there's still a long way to go in terms of retrieving metals from electronic waste across categories, not just electric vehicles. Aside from this, by lessening its dependence on mining, EV manufacturing can also distance itself from the many problematic practices that plague the mining industry, such as human rights abuses and environmental impact.

With up to 40% of an EV's cost due to its battery and the main culprit behind its high price point, reducing precious metal costs could also potentially make EVs more affordable for the average person. Since cost is a common barrier that keeps people from buying EVs, this could mean faster adoption rates and ubiquity for EVs on the road.