Titanium-Gold Alloy Makes Ultra-Hard Artificial Joints

Researchers have developed a new type of alloy that is said to be four times harder than most type of steel, the end goal being artificial joints that are harder and more durable. In the present day, titanium is the preferred type of metal for these artificial joints. In the future, though, a titanium-gold alloy may be used instead, with the mixture being about three parts titanium to one part gold. The alloy is four times harder than titanium.

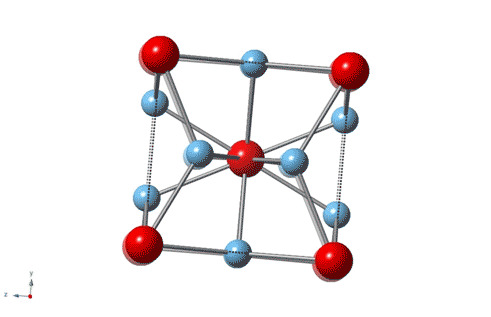

This isn't a new metal, it should be stressed, and researchers say it isn't difficult to make. However, this may be the first time a pure sample of the alloy metal was produced, and researchers with Rice University were the first ones to document the hardness properties of the metal. This hardness is largely thanks to the alloy's cubic molecular structure, shown below, with the cubic nature lending the hardness.

The hardness became apparent when researchers tried to grind the metal alloy into a powder for analysis. They weren't able to grind it down, with even a diamond-coated mortar and pestle failing to pulverize it. The key to the ultra-hard nature is creating the alloy at a high temperature — when created at lower temperatures, the metal alloy is the same hardness as regular titanium due to the arrangement of a different cubic structure.

Further tests performed by researchers with the University of Texas found this alloy has better biocompatibility over regular pure titanium. It could one day be used in artificial joints, as well as dental fillings and other implants, resulting in products that can hold up better to wear and tear without triggering any rejection responses from the body.

SOURCE: Rice University