Researchers Create A New Method For Building Anti-Bacterial Graphene Masks

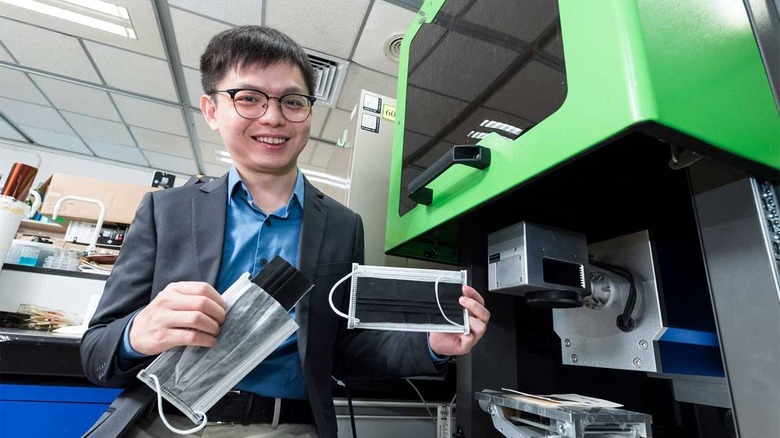

Researchers from City University of Hong Kong have developed a new method for making antibacterial graphene masks quickly and cost-efficiently. The researchers note that commonly used surgical masks are not antibacterial, leaving harmful elements on the mask to remain active for hours, posing a secondary infection risk. Graphene is known for its antibacterial properties, and scientists have studied making graphene masks.Researchers say that in past studies, they discovered that direct writing on commercial polyamide films or other biomaterials using a commercial carbon dioxide infrared laser system could generate 3D porous graphene. This technique makes the fabrication of graphene masks quick and easy. Early studies on the graphene masks are underway.

The laser-induced graphene material can kill almost all E. coli and aerosolized bacteria. Destroying bacteria is induced by graphene-bacteria interactions and can kill 99.998 percent of bacteria within 10 minutes. Initial tests with two coronavirus samples found that the material inactivated over 90 percent of the virus in five minutes and all of the virus in 10 minutes.

One problem with using other conventional methods for producing graphene is that users have poor control over the product's shape. The process also requires high-temperature conditions along with lengthy synthesis routes and high cost. The method of creating graphene the university is using combines graphene preparation and patterning into a single step.

Researchers can convert most carbon-containing materials, including cellulosic paper, into graphene. Researchers are also able to use biomass or biomaterials. The process can be carried out under ambient conditions using a laser system found in most machine shops. Pricing for the graphene masks is expected to fall between a standard surgical mask and an N95 mask. Researchers have also created a hygroelectric generator powered by human breath that can report the mask's condition.