New Carbon Fiber Composite Can Be Healed Using Heat

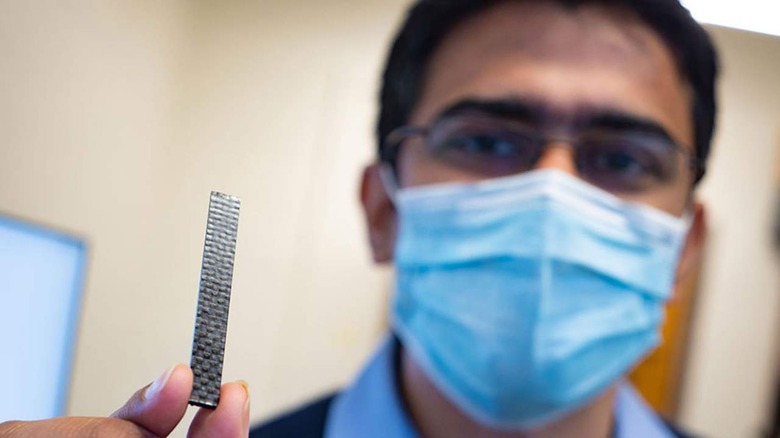

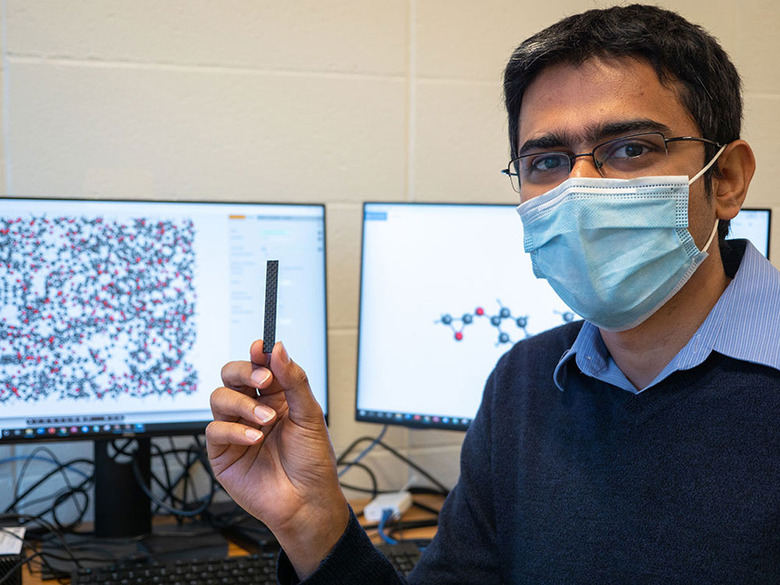

University of Washington professor Aniruddh Vashisth has developed a new, very strong, and lightweight carbon fiber composite material. This new carbon fiber composite material differs from traditional carbon fiber because it can be repaired repeatedly. With current carbon fiber materials, it's essentially impossible to repair or recycle the material once it's damaged.

The new carbon fiber composite material is just as strong as traditional carbon fiber but has the benefit of being repeatedly healable using heat. The heat can reverse any fatigue damage to the material, and it can also be used to break the material down when it's time for recycling. With the inability for the traditional carbon fiber to be recycled, developing a material that can be recycled or repaired using traditional heat sources or radiofrequency heating is a critical discovery.

Professor Vashisth says heat sources can be used to postpone the aging process of his new carbon fiber composite indefinitely. The material falls into a group known as carbon fiber reinforced vitrimers (vCFRP). By comparison, the carbon fiber material typically used today is carbon fiber reinforced polymers (CFRP). Traditionally, CFRPs are either thermoset or thermoplastic. Thermoset varieties use an epoxy with chemical links that hold it together and harden permanently. Thermoplastic varieties use a softer glue that can be melted down and reworked, but doing so impacts its strength and stiffness.

vCFRP relies on vitrimers that can link, unlink, and relink to provide a middle ground of sorts compared to the other two materials. Project researchers believe the vCFRP material is an alternative for many products manufactured from thermosets and could prevent a buildup of carbon fiber materials in landfills. The material would take the linear lifecycle of plastics and turn it into a circular one, similar to aluminum.

One of the places where carbon fiber composites are commonly used today are in wind turbine blades. One of the biggest downsides to those wind turbine blades is that the material can't be recycled. Those blades also have a finite lifespan, and since they can't be recycled, when it's time to be replaced, the old blades are placed into a landfill. Thousands of these blades will be removed from wind turbines used for generating electricity in the coming years. Those blades will never break down in the environment and will remain where they are placed forever.

The problem with recycling materials made from carbon fiber composites, such as wind turbine blades, highlights a little-known challenge with wind energy. Not everything associated with renewable electricity is recyclable. Some required components for generating clean electricity create problems for the environment on their own.

If these blades can be created using the new vCFRP in the future, perhaps heat could simply be used to renew the blades making them ready for operation again. Even if they could not be healed and reused, at least heat could be used to break them down rather than simply burying them in a landfill forever.