Implosion Fabrication: MIT Can Now Shrink Structures To Nanoscale

It's called Implosion Fabrication. They can't quite shrink humans yet, but they can print a very tiny version of most any shape you choose. The MIT responsible for this project invented a way to capture the shape of an object and replicate it, further shrinking it down to nanoscale upon drying. It's sort of like Ant Man and the Wasp (2018), but just a little bit different.

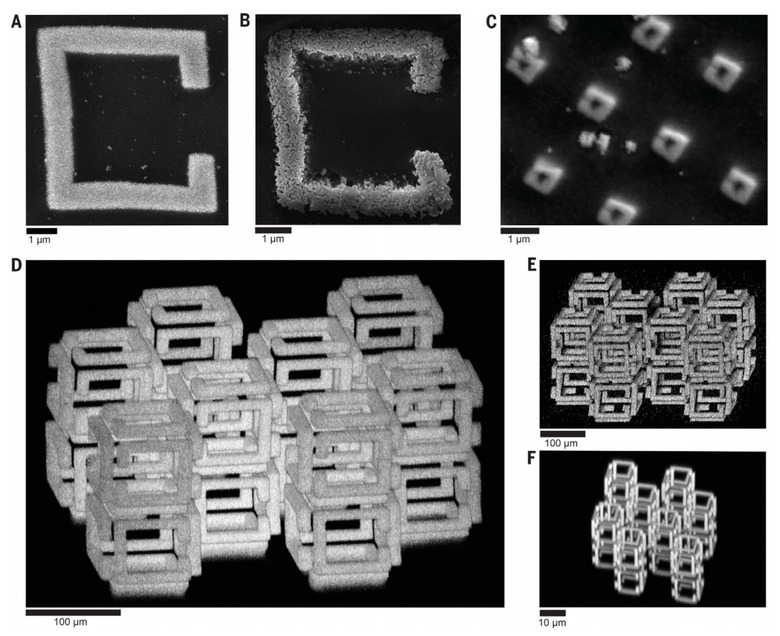

The team tackled the limitations of the otherwise current and most complex methods of 3D printing materials. Normally this required a series of stacked layers, "which restricts three-dimensional (3D) geometry." Instead of printing in thin air, the team used a gel scaffold.

Inside this gel scaffold, objects of many sorts were fabricated using current-day hardware. They created a way to make the direct assembly of 3D nanomaterials in almost any 3D geometry a reality. Nanomaterials used in testing included metals, semiconductors, and biomolecules of many sorts.

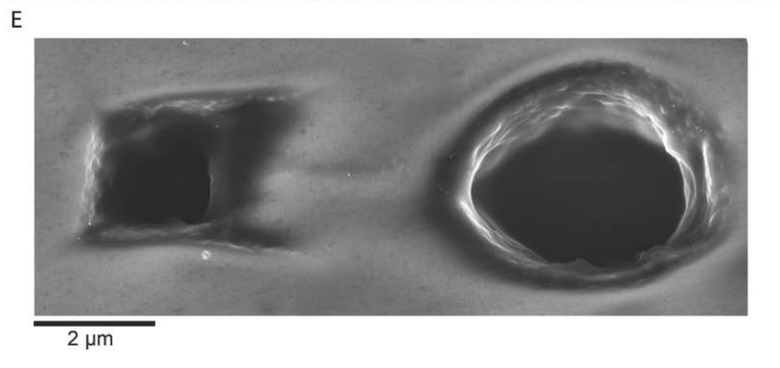

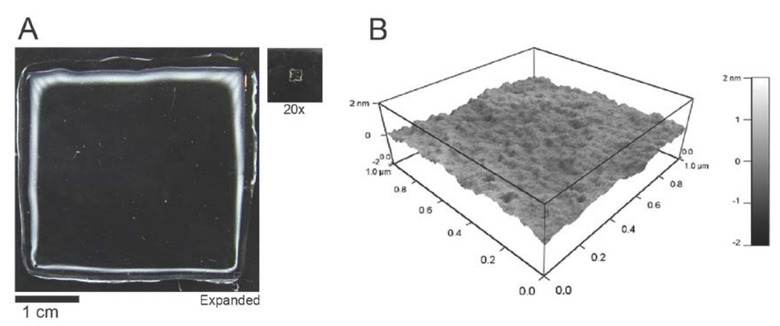

ABOVE: "SEM image of 20x shrunken and dehydrated gel, showing ablation of the gel substrate corresponding to a patterned square and circle upon the use of excessive laser powers. In the course of developing the current manuscript, we found that gel ablation in this way could be used to generate complex three-dimensional structures, but those structures would not typically survive the dehydration process."BELOW: "(A) Photographic images of a gel before (left) and after (right) shrinking and dehydration (20x gel). (B) Atomic force microscopy (AFM) smoothness measurement performed on a 10x shrunken and dehydrated gel, unpatterned, showing surface smoothness in the nanometer range across length ranges of ~1 micron."

"We used hydrogels as scaffolds for volumetric deposition of materials at defined points in space," wrote the researchers. "We then optically patterned these scaffolds in three dimensions, attached one or more functional materials, and then shrank and dehydrated them in a controlled way to achieve nanoscale feature sizes in a solid substrate. "

The method for printing and shrinking in this manner they called Implosion Fabrication, or ImpFab. Because they're printing inside a polyacrylate gel (hydrogel) scaffold, they're able to create non-self-supporting 3D arrangements of materials. Upon shrinking, the team achieves "resolutions in the tens of nanometers."

The researchers used two-photon microscopy to pinpoint points within their hydrogel. They use fluorescein molecules as anchors, allowing binding with other sorts of molecules also added by the researchers. Edward Boyden, the Y. Eva Tan Professor in Neurotechnology and an associate professor of biological engineering and of brain and cognitive sciences at MIT, is one of the senior authors on the research.

"You attach the anchors where you want with light, and later you can attach whatever you want to the anchors," said Boyden. "It could be a quantum dot, it could be a piece of DNA, it could be a gold nanoparticle."

After the structure is complete, researchers add an acid that allows the hydrogel (and the structure) to shrink. The negative charges in the gel are blocked, and the gel contracts. With this method, these researchers are able to shrink structures approximately 1,000-fold. Absolutely bonkers science in full effect!

To learn more about this subject, take a peek at the paper "3D nanofabrication by volumetric deposition and controlled shrinkage of patterned scaffolds" as published this week in Science. Authored by D. Oran el al., this paper can be found with code DOI: 10.1126/science.aau5119 as published on the 14th of December, 2018.