GM Slows Production At Four Manufacturing Facilities Due To Chip Shortage

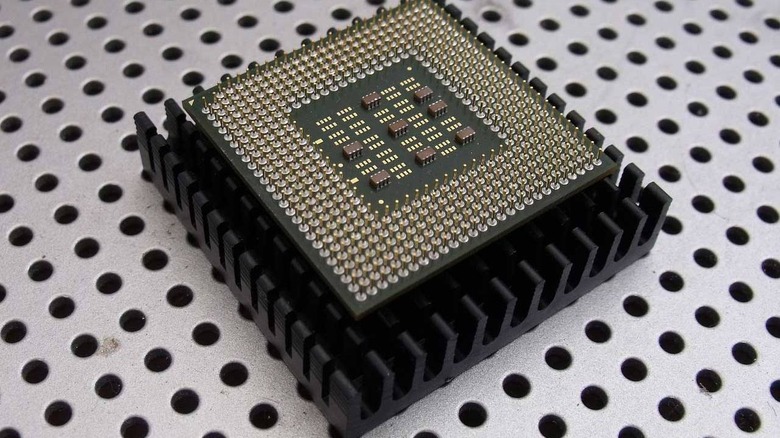

The coronavirus pandemic has put a crimp on manufacturing operations all around the world. As infection caused manufacturing operations to slow in China, where much the world's supply of electronics and microchips comes from, the downstream effects of that have been impacting other manufacturers all around the world. The latest to be impacted is General Motors. It has announced that the global shortage of semiconductor chips is forcing the automaker to cut production at four of its manufacturing facilities.

GM has confirmed that it will stop production entirely during the week of February 8 at manufacturing facilities in Fairfax, Kansas: Ingersoll, Ontario: and San Luis Potosi, Mexico. General Motors also intends to operate a plant in South Korea called Bupyeong 2 at half capacity. It's unknown how much volume the automaker will lose or which supplier was impacted by the chip shortage. The automaker has been focusing on keeping production running in plants that build its most profitable vehicles.

Facilities that have continued operating include those that are building its full-size pickups and SUVs, as well as the Corvette. GM has said that it wants to make up as much lost production as possible at the closed facilities. Analysts think that GM's combined lost volume will total almost 10,000 vehicles during the week.

GM has been clear that it has conducted mitigation efforts, and despite them, the semiconductor shortage is impacting production. GM vehicles that will be slowed include the Chevrolet Malibu sedan, Cadillac XT4 SUV, Chevy Equinox, Chevy Trax, GMC Terrain, and the Buick Encore. GM isn't the only automaker impacted by the chip shortage. Production has been cut due to the same issue by Volkswagen, Ford, Subaru, Toyota, Nissan, and Stellantis. Overall, the shortage of chips is expected to reduce global auto production by 672,000 vehicles for the first quarter.