Four Reasons Quad-Motor EVs Should Excite You

Spinning on the spot, powering out of twisty corners, or just avoiding getting bogged down in mud: there are several good reasons why you might want your next electric vehicle to have four motors to play with. Until now quad-motor EVs have been the expensive preserve of electric exotica, but we're finally seeing automakers flirt with the idea that "more is better." Here's why that should excite you.

Say hello to Tank Turn

A tight turning circle can be a joyous thing when you're trying to navigate down a crowded city street, squeeze through a jam-packed parking garage, or just turn your car around on the driveway. How much better would it be if, like a tank on tracks, you could just spin the car around? Welcome to the beguiling world of "tank turn."

To spin on the spot, a tank sets the tracks on one side to run forward, and those on the opposite side to run in reverse. The end result is a pivot in place. Problem is, cars and trucks don't usually have tracks.

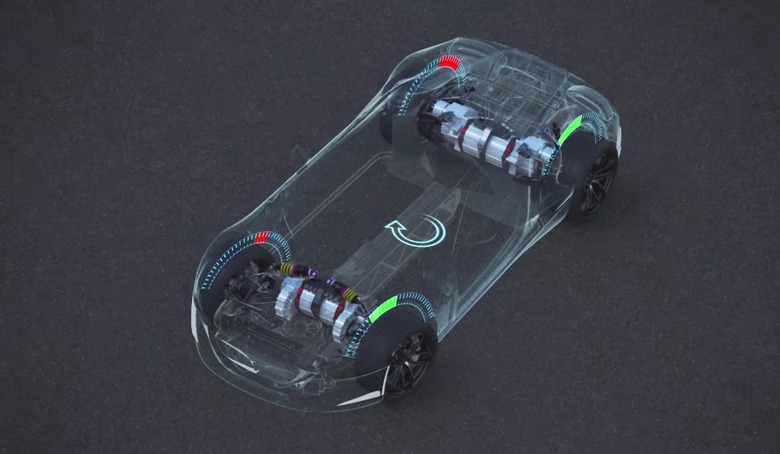

Instead you need a way to individually control each wheel, effectively making the front and rear wheels on the left side spin in one direction, and those on the right spin in the opposite direction. The easiest way to do that is by giving each wheel an individually-controlled electric motor, just like we've seen Rivian tease on the R1S SUV and R1T pickup truck.

Four motors means proper torque vectoring

Torque vectoring is in many ways the holy grail of eager drivers. Usually, as you turn a corner, the inside wheel and the outside wheel are rotating at the same rate. With torque vectoring, the outside wheel can get more power, pushing the car into a sharper, tighter turn.

There are plenty of ways to do torque vectoring, some more successful than others. Most common is brake-based, where the inside wheel is slowed slightly by applying the brakes to one side of the vehicle but not the other. That can be effective, but it means you're squandering power: torque is being sent to the wheel, but you're artificially reducing its efficacy.

Better is a torque vectoring differential. That has the same outcome – slowing the inside wheel – but it does so by actually reducing torque to that wheel. At the same time, the torque is increased to the outside wheel, meaning you're not wasting power overall.

When you get to an EV, things can be even more interesting. Then you can have an electric motor dedicated to each wheel, each independently controlled. It can be faster and more responsive, too, since it's adjusting torque electronically – by how much power goes to each motor – rather than mechanically.

The upshot is an improvement both in driving dynamics when you're feeling sporty, and stability when you're focused on safety. If your EV spots that the wheels on its left side are slipping in mud, for example, it can prioritize power to those on the right side and make sure you have traction. In tight corners, the outer wheels can be spun faster than their inner counterparts, tightening turns.

Triple-motor torque vectoring EVs look to be a stepping stone to all this. That's what Tesla has in mind for the 2020 Roadster, with each rear wheel getting an electric motor of its own, and the front wheels sharing a third motor. Acura's NSX may not be all-electric, meanwhile, but it has two front electric motors and then a third for the rear, the latter working in tandem with a gas engine for hybrid power.

With four e-motors, there's more packaging choice

It'd be understandable to assume that, with four electric motors rather than two or three, fitting them into an EV and still having usable space for passengers and cargo might be a problem. In reality, there are some big potential packaging advantages if each wheel has a motor of its own.

Take the traditional rear- or all-wheel drive vehicle, with an internal combustion engine. The power from the engine at the front has to get to the rear axle: that means a driveshaft running the length of the car. It usually intrudes into cabin space as a result.

In an AWD electric vehicle, with two motors, you can get away with no mechanical connection between the front and rear axles. Hang the battery under the cabin, and you get lots of uninterrupted space for passengers. Things get even more flexible if you use two electric motors for each pair of wheels, rather than one. That way, you can use two, smaller motors rather than one big one on an axle, and split them out to the sides of the vehicle.

It'll arguably be even more efficient when in-wheel electric motors start to make it to production vehicles. Then the majority of the motor is actually contained within the wheel itself, further pushing the hardware out to the periphery of the car and freeing up even more space in the body for more practical uses.

Not all four-motor EVs will be the same

Just as there's no single "best" way to configure an internal combustion car, so too there's no one way to put four electric motors into an EV. In-wheel systems have some major packaging advantages, true, but they also come with downsides too. Think of them as an interesting option, not the holy grail.

Another possibility is separating out the motors from the wheels, each getting a gearbox of its own. We've seen Rimac do that with its Concept_One and C_Two hypercars: each wheel has a motor, with either a single- or two-speed transmission connecting them. It means the motors don't count against the car's unsprung mass, as is the case with in-wheel motors, and it also means each motor needn't put out the massive quantity of torque an in-wheel motor will, since the gearbox can step that up.

By playing with the configurations, different automakers will be able to set up different drivetrains, each suited to different types of vehicle and driver. An electric pickup truck like the Rivian R1T, for instance, will face very different demands and expectations to, say, a four-motor electric sports car. Whatever the layout and the strategy, one thing is clear: with EVs, there are at least four reasons why more is better when it comes to motors.