ESA's Reusable Prometheus Rocket Engine Will Be Ground Tested In 2021

In 2017, the European Space Agency tapped ArianeGroup to develop Prometheus, a full-sized and liquid-fueled rocket engine demonstrator intended to pave the way for reusable rocket engines. At the time, the agency had said that its demonstrator would be ground tested in November 2020; this week, the ESA returned with an update on the project, including some new dates.

Reusable rockets are the future of space travel; they enable the systems to be used multiple times before they're retired, reducing the cost of each mission and making it possible to launch multiple missions at a faster pace. SpaceX has pioneered this reusable rocket industry, giving the world a look at what is possible.

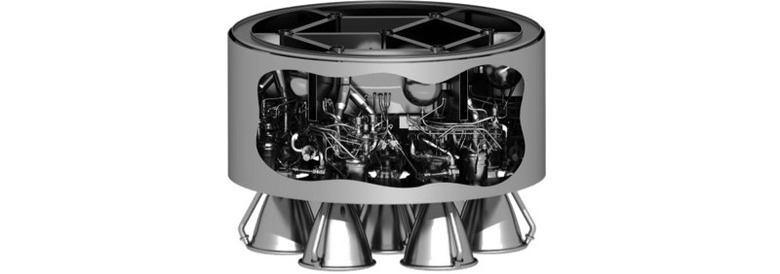

The Prometheus rocket engine will be powered by liquid oxygen-methane propellants, which the ESA says is readily available with high levels of standardization and efficiency. Some of the rocket components will be created using what is essentially 3D printing technology, helping keep costs down.

In addition to its lower cost and highly efficient fuel source, the rocket engine will also be more flexible than current offerings — the ESA explains that it will be suitable in a larger variety of launch vehicles, as well the anticipated future engines that result from this research.

In an update published on June 4, the ESA said that it is moving ahead with this project; it recently received full funding to evolve Prometheus, bringing it 'to a technical maturity suitable for industry.'

The agency anticipates this rocket engine costing only 1/10th that of the Ariane 5 Vulcain 2 main stage engine. Prometheus will be suitable for both the upper stage and main stage usage, according to the ESA, joining other features to be 'highly flexible.'

At this time, the engine's main subsystems are being manufactured, a process that includes additive layer manufacturing (ALM) that constructs the components one layer at a time. This process is faster than traditional methods, which are also unable to produce some of the complex parts required for the design.

Some components are already finished and ready for testing, including the pump inlet, turbine, and gas generator valves. The initial combustion chamber model will be tested later this month if everything goes according to plan; the combustion chamber will be delivered later this year. The full-scale demonstrator — which has been named 'M1' — will then be assembled for ground testing next some time next year.