ESA Prometheus Low-Cost Reusable Rocket Engine Moves Forward

The European Space Agency or ESA is working on a precursor to an ultra-low-cost rocket called the Prometheus. The space agency says that the rocket is flexible enough to be used on a fleet of new launch vehicles for any mission. The rocket could also potentially be reusable, saving costs making launches cheaper.

Last November, the ESA received full funding to bring the current Prometheus engine designed to a technical maturity suitable for industry. Prometheus was developed by ArianeGroup and is seen as key in the effort to prepare for future competitive European access to space. The ESA is aiming to lower the cost of production by a factor of 10 compared to the current main stage Ariane 5 Vulcain 2 engine.

Prometheus features variable thrust, multiple ignitions, suitability for both primary and upper stage application, and minimized ground operations before and after a flight. The agency says that all those features combine to make Prometheus a highly flexible engine. The current Prometheus precursor runs on liquid oxygen-methane, adding high-efficiency and allowing standardization and operational simplicity. Methane propellant is widely available and easy to handle according to the agency.

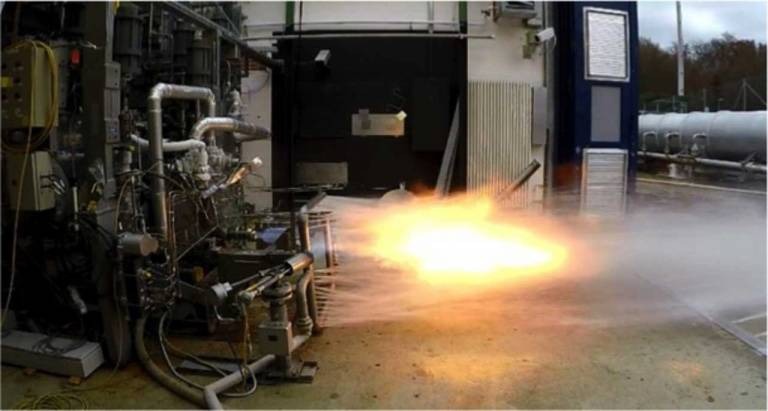

Upcoming tests will be conducted in Germany to validate the hardware components for the first Prometheus engine test model. Europe for the tests, the P5 test bench will gain a 250 cubic meter capacity propellant tank for methane. The addition of that tank will allow engineers to switch test configurations between Prometheus and the Vulcain 2.1 main stage engine that is also in development.

Prometheus is using additive layer manufacturing to speed up production, which also helps to reduce costs significantly. The process allows the construction of very complex and optimized parts that are impossible to manufacture using other methods. Components using the process include the turbopump turbine, pump inlet, and gas generator valves.