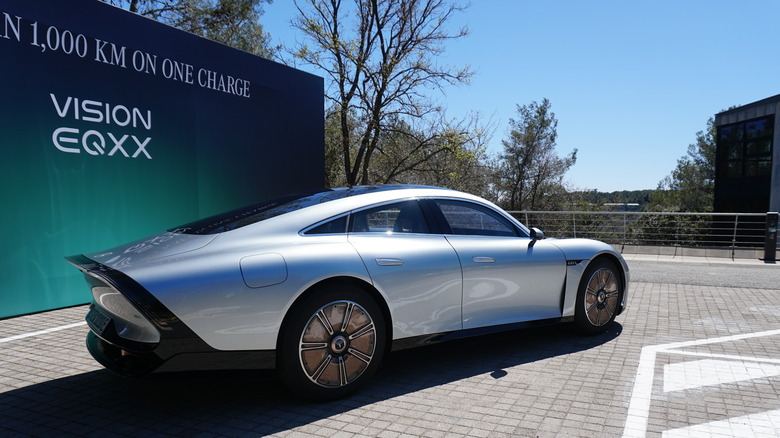

Mercedes-Benz VISION EQXX Research Car Co-Drive: Record-Setting EV Range

On April 5, 2022, Mercedes-Benz took a record-setting road trip in its VISION EQXX electric "research" car from the company's new Electric Software Hub in Sindelfingen, Germany, to Cassis, France — all without recharging the sedan's 100 kWh battery. Winding through the Alps of Switzerland in rain and cold weather, and down through Italy before reaching its destination, the trip took just over 12 hours, including two 15-minute breaks to switch drivers. The 1,008 km (626 mile) ride on a single charge was verified by the internationally accredited certification body TÜV SÜD.

Five days later, we were part of the first small group of people outside of Mercedes-Benz to ride in the VISION EQXX. It was a brief half-hour "co-drive" (where we did none of the driving) through the scenic Côte d'Azur region of the south of France. However, it was a long enough sensory experience to soak in some of the innovations of the experimental car, with which Mercedes-Benz plans to make much more than a conceptual impact.

Innovation lab on wheels

While many people have referred to the VISION EQXX as a concept car, those people do not work at Mercedes-Benz. The company insists on calling it a research vehicle, because it concentrates experimental projects from many areas of research into a single, practical EV for the express purpose of testing the results in real-world scenarios. During the VISION EQXX technological briefings on the day of our co-drive, Jasmin Eichler, Director of Future Technologies for Mercedes-Benz AG, said the best of those lessons will be used in all Mercedes series vehicles.

Eichler says the point of the VISION EQXX's 1,000 km road trip was not simply to finish the drive on a single charge. For that, she says, they could have simply put a bunch of extra batteries in the roof to extend the range. Instead, Mercedes-Benz set out to make the most efficient EV yet by bringing together research innovations in the electric powertrain, battery, aerodynamics, lightweight body construction, infotainment and computing, and sustainable interior materials.

When Mercedes-Benz revealed the VISION EQXX in January, the car had been in development for 18 months at that point, and Eichler said they were not sure it would complete the 1,000 km trek on one charge. Since then, the team removed another 88 pounds from the car, bringing its unladen weight down to 3,869 pounds. In the end, by the time the VISION EQXX arrived in Cassis after 1,008 km, its battery was 15% charged, potentially allowing another 140 km (87 mile) range. It had averaged just 8.7 kHw per 100 km driven.

Engineering for endurance

Developed in tandem with the Mercedes-AMG Petronas F1 team, the VISION EQXX's electric drive unit achieves a peak output of 180 kW from a single rear-axle motor. According to Eva Greiner, Chief Engineer, Electric Drive System for Mercedes-Benz AG, the VISION EQXX drivetrain is 95% efficient, meaning 95% of the battery energy gets to the wheels. She says the average electric drive efficiency is about 90%, so the VISION EQXX reduces energy losses by 50% off the average. Because the efficient drive unit generates little wasted heat, the engineers could cool it using only passive cooling, and that saves further energy by avoiding liquid cooling.

While the VISION EQXX's 100 kWh battery pack holds a little less energy than the 107.8 kWh battery in the EQS luxury sedan that's currently available, it has a much higher energy density of 400 Wh/l, allowing it to take up 50% less space. It's also 30% lighter than the EQS battery.

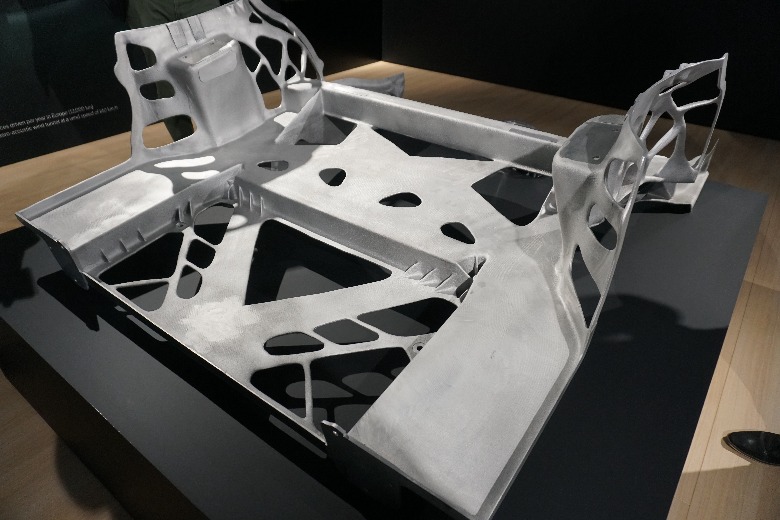

Extreme weight loss

Lightweighting overall was very important to the engineers, who utilized AI-assisted topology optimization software to design many of the body's parts. The process removes material where it's not needed for structural strength, resulting often in organic, even skeletal-looking shapes. These parts are prototyped using 3D printing but then fabricated at production scale using casting. In particular, the aluminum-cast BIONEQXX rear floor replaces several heavier parts with a single, large piece that's 20% lighter.

A lighter car helps especially to consume less energy on uphill climbs, like the nine-mile uphill portion of the VISION EQXX's epic drive in Switzerland, which had incline grades of up to 5%. Of course, that was eventually followed by a long downhill stretch coming out of the Swiss Alps.

The VISON EQXX can regenerate energy for the battery during any braking and on any level of downhill gradient. So the mechanical brakes are rarely needed at all except for complete stops. That allowed the engineers to employ aluminum brake discs for the first time, which saves weight compared to steel brakes and also prevents the brakes from rusting.

Even the car's solar roof saves weight by not incorporating any glass in the 117-cell solar array. This sends power to the 12-volt battery, which supplies the infotainment/navigation system and lights. Supplementing the main battery pack's energy with the solar roof can increase the car's range by more than 2% according to Mercedes-Benz, which amounted to about 25 km (16 miles) during the 1,008 km ride.

Calling mission control

For the long journey, three developers on the VISION EQXX team drove the vehicle. Mercedes-Benz did not want to use professional drivers, to reflect more closely a real-word scenario. The drivers did, however, receive an assist from their co-workers back home. Telemetry sent copious amounts of data from the vehicle back to the Electric Software Hub in Sindelfingen for analysis and tests.

The VISION EQXX's software was still being optimized and not completely finished, so this remote collaboration helped to salvage the experiment when it may have been in jeopardy. In her presentation, Greiner disclosed that there was "a little issue" during the marathon road trip, and the software team in Germany was able to help. The AC/DC convertor was not working at its full level. But they were able to simulate the problem at the home office and then tell the current driver what to do to fix it.

All about air flow

Teddy Woll, Head of Aerodynamics for Mercedes-Benz AG, says that 62% of the car's energy is used "just to push air out of the way," while 20% of it goes to rolling resistance from the weight and tire efficiency. So aerodynamics were of the utmost importance to make the VISION EQXX as efficient as possible.

Many considerations were made to get the car's drag coefficient all the way down to 0.17, appreciably lower than the 0.2 cd rating of the EQS and even lower than the team initially expected to achieve. Passive cooling to the drivetrain comes from an underbody cooling plate using the air flowing along it in an aerodynamically efficient way that itself can increase range by up to 2% or about 20 km (12 miles) per charge.

A low rear diffusor automatically activates quietly at 37 mph, providing better airflow to reduce drag. Woll says that it's heavy but consistent with the design and worth the weight for its aerodynamic benefit. He says the diffusor can increase the range by 4-5%.

The rear-view mirrors and wheels were also designed for aerodynamics. There's no dish between the wheel's outer lip and spokes, and Mercedes-Benz worked with Bridgestone, which created tires specifically for the VISION EQXX, to make the transition from tire to wheel rim aerodynamic. The tires themselves have a large diameter but a narrow tread to reduce weight. And they have a rolling-resistance rating of 4.7, compared to a 5.9 rating for the EQS tires.

Design vs. engineering

Birds and fish inspired the sleek shape of the VISION EQXX for their ability to glide with low resistance. For example, the vehicle's small surface area in front helps air flow over it. However, the wheels caused a conflict between the aerodynamics engineers and designers. Woll's team wanted the rear wheels to be narrower than the front wheels, which the designers protested. Both parties call this conflict normal and in fact welcome, because such conflict generates creative energy. A compromise allowed the rear wheel set to be 50mm narrower than the front, which was still enough for the rear wheels to roll in the slipstream of the front wheels for better aerodynamics.

Woll also says that every past Mercedes vehicle with a drag coefficient of 0.2 or less had wheel spats, which the designers did not want in order to maintain the beauty of the car. So by finding aerodynamic gains in other places, they preserved a design without spats.

The brains of the operation

A "pillar to pillar" micro LED display, the largest display ever in a Mercedes, stretches from one end of the VISION EQXX dashboard to the other. According the company, it is even more energy-efficient than an OLED display, in part because when an area of the display is black, it turns off the pixels for that area, saving energy and creating great contrast. This screen is the heart and—if you cross the uncanny valley—soul of the car. That's because the digital assistant that responds to the "hey Mercedes" cue runs off "neuromorphic computing" from California AI company BrainChip. This utilizes a machine-learning neural network that only draws energy in "spikes" when called upon and over time can be 5-10x more efficient than conventional voice control, according to Mercedes-Benz.

The onboard computer also uses a game engine from an undisclosed developer to power the UI's real-time graphics. If you ask for nearby grocery stores for example, it adapts to blow up only the grocery store locations on the map. The five "tech views" you can swipe through on the display show off the combined computing power with real-time data visualization for the VISION EQXX's energy usage, aerodynamics performance, range predictor, solar generation, and wind conditions. Sensors pick up the direction and speed of the surrounding winds. So for example, if there is wind at your back, you can let up on the acceleration a bit to preserve energy.

Department of the sustainable interior

For the interior, Mercedes-Benz seeks to "redefine luxury" by working with suppliers of new and emerging sustainable materials based on recycled and/or plant-based sources without compromising quality, comfort, and style. Two types of leather alternatives come from a cactus-based biomaterial called Deserttex from Mexico, used for broad pieces like the seats, and for smaller inserts, a processed mycelium fungus material called Mylo. A synthetic silk called Biosteel from AMSilk is spun from a protein powder culled from E. coli bacteria fed starch in a lab. The material is very strong and lightweight compared to other textiles and serves as the VISION EQXX's door handles and other elements.

From floor to ceiling, the car's blue trimmings are green. A plush, shag-like carpet comes from 100% bamboo fiber, and the interior lining is made of 100% recycled polyester textile. This lining has been in series production since the EQC electric luxury SUV, although with a lower percentage of recycled plastic.

Another material scheduled to grace the series production of the EQS and EQE electric sedans we find perhaps the most fascinating. UBQ is a thermoplastic derived from unsorted landfill waste. Basically any type of household garbage gets converted to a powder first and then to pellets of bio-based thermoplastic. Those pellets can feed into 3D printing and injection molding without any factory retooling. In the VISION EQXX, UBQ shapes are electroplated and installed inside the headrest around the in-seat speakers for noise control.

Along for the ride

Stepping into the VISION EQXX for the first time, the aesthetics of these sustainable materials stand out not just as visually bold, but also pleasant to the touch. The Deserttex faux-leather of the seats is supple but seemingly robust. The polyester textile lining takes on the approximate feel of suede. Probably in the name of efficiency, there are some unusual design elements, such as exposed metal behind the seat cushions to use less material and no rear window so the solar roof can be larger. However, the seats are still quite comfortable, and the driver for my ride-along said he personally didn't mind using just the rear-view mirrors in lieu of having a rear window.

When the car starts, the long, one-screen display comes to life and begins a greeting from the voice assistant. It tells you about the navigational route for the drive and makes some suggestions for stops along the way. The voice does sound natural and expressive as promised. However, it's far too conversational and proactive for our preference, so we'd dial that way back in the settings.

Rather, the highlights of the infotainment system are the tech view screens that show a remarkable amount of data in real time. For instance, one screen shows the current drag coefficient with the state of the diffusor and air cooling shutter. Another shows the angle of the sun to the solar roof and the solar power generation. An energy usage screen lists the percentage of drive efficiency and a list of eight factors that are either helping or hindering efficiency.

Look and feel

The amount of constantly-updated data available from the system can stagger the mind, but it's working to help you drive more efficiently if you choose. And the drive itself — or in this case, the ride — measures up to the technology on board. While the VISION EQXX has its own unique electric drive system, but we didn't get all the specs on its suspension, horsepower, torque, and so on. However, having just driven the 2023 Mercedes-Benz EQE 350+ and EQE 500 4MATIC electric sedans three days prior, the VISION EQXX felt more or less similar to the single rear-axle motor EQE 350+ in terms of the acceleration power, feel of the regenerative braking modes, and the smoothness of the handling, despite it having slightly less peak output power.

It certainly has a very minimal interior control scheme, fixtures, and other amenities, except for the loaded steering wheel controls. While the VISION EQXX succeeds at mimicking a practical car for real-world drives, it does intentionally cut a few driver-centric interior features for streamlining.

Then there's the pure elegance of the VISION EQXX's contoured design. Beauty is of course subjective, but we can't help gushing just a wee bit over its luscious appearance. The classic curves subtly harken back to some of the best Mercedes-Benz 300 models of the '50s and '60s, but with the stark refinement of modern-day materials and aerodynamics. If the VISION EQXX were actually available to own, it would be not only the most efficient but also the coolest-looking car on most blocks.

Seeing into the future

That's unlikely to ever happen though, as the VISION EQXX is not slated for production. And that does make it fit the simplest definition of a concept car. But at least we know for sure that the most proven and practical of its innovations will trickle down to other Mercedes-Benz series cars.

Eichler, who ended her presentation with a video the VISION EQXX's successful 1,008 km journey with tears of elation in her eyes, says that roughly speaking, 1/3 of the experiments in the VISION EQXX will be put in series production, 1/3 of them will not, and 1/3 of them are already in series vehicles.

Setting aside the semantics of whether the VISION EQXX is a concept car or a research vehicle, the concept of using this grand experiment to funnel new technology into Mercedes-Benz series vehicles has resulted in a car that we'd love to drive if we could. Fortunately, with the German automaker vowing to have an all-electric option for every Mercedes-Benz model available by 2025, more of the VISION EQXX's lessons should make their way to commercially-available Benzos before too long.