Here's Why (Most) Diesel Engines Don't Have Throttle Bodies

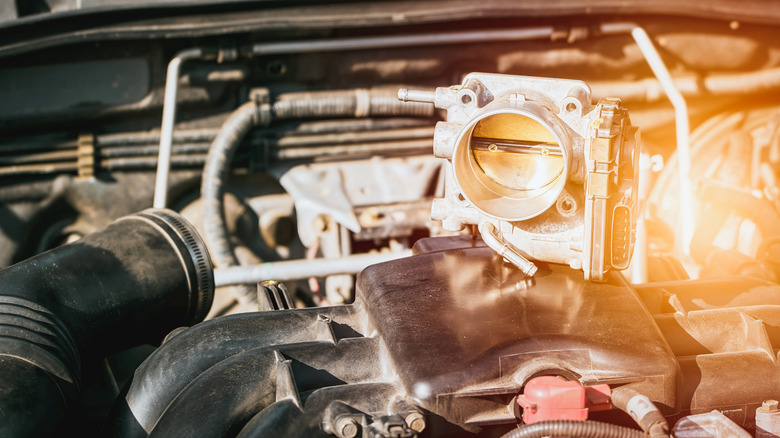

You might already know that gasoline and diesel engines both operate using the same four-stroke cycle: intake, compression, power, and exhaust. However, a key difference between gas and diesel engines is how they generate and regulate power. Most gasoline engines have a throttle body to control airflow into the cylinders. When the driver presses the accelerator pedal, the throttle plate opens to allow more air in, and the engine control unit (ECU) then adds the appropriate amount of fuel. This system provides a balanced air-fuel mixture perfect for combustion. Diesel engines, by comparison, do not rely on a throttle body to regulate airflow.

Instead, they control power output by metering the amount of fuel injected into the combustion chambers. The absence of a throttle body is also a product of diesel engines' reliance on compression ignition. Unlike gasoline engines, which use spark plugs to ignite a precisely metered air-fuel mixture, diesel engines compress air until it becomes super-heated. It's then mixed with fuel that's been injected directly into the combustion chamber. The heat of compression is enough to ignite the fuel, effectively eliminating the need for spark plugs or precise air control via a throttle body. This comes with several useful advantages.

Efficiency of diesel engines explained

One of the biggest advantages of diesel engines over gasoline engines is efficiency. They operate without a throttle plate, allowing unrestricted air intake and reducing vacuum pressure losses. There's also an advantage in how and where the fuel and air are mixed. In gas engines, the fuel/air mist has to travel through the intake manifold to the cylinders, while in most diesel engines the fuel is sprayed directly on top of the pistons. The much higher compression ratios of diesel engines (typically 16:1 to 20:1, compared to 9:1 to 12:1 in most gasoline engines) also allow them to extract more energy from each unit of fuel.

This high compression also contributes to diesel's superior torque. Diesel fuel has a higher energy density than gasoline, and the combination of high compression and turbocharging common in modern diesel engines produces significant low-end grunt. That's why diesel engines are the go-to choice for heavy-duty trucks, industrial machinery, and high-efficiency passenger vehicles: they deliver smooth, continuous power with minimal mechanical resistance.

Where diesel engines use throttle valves

Though most diesel engines lack throttle bodies, they do employ similar components. For instance, some modern diesel engines incorporate throttle valves in exhaust gas recirculation (EGR) systems, although this is for emissions control and not fuel delivery. By restricting intake airflow with a throttle valve, manufacturers can increase EGR rates, which helps reduce nitrogen oxide (NOx) emissions. Some diesel engines also use throttle valves to provide smoother engine shutdown by cutting off the air supply during the shut-off process.

This reduces vibration and potential engine damage. Exceptions aside, the most important fact remains: In most diesel engines, power output is regulated by fuel injection, not by controlling airflow. Understanding this distinction helps explain why diesel engines are preferred for heavy-duty applications and how they continue to play a critical role in industries that demand high efficiency and torque.