Battery Teardown Pits Tesla Against Its Biggest Rival (And Elon Musk Should Be Worried)

At the start of 2025, Chinese carmaker BYD was crowned as the world's top seller of electric cars, surpassing Elon Musk-led Tesla in the last quarter of 2024. The success of BYD is not surprising, as the brand offers a much wider portfolio of cars, and at rates that often undercut what Tesla has to offer. However, variety and pricing aren't the only aspect driving BYD's success, as the company's tech stack is also quite impressive.

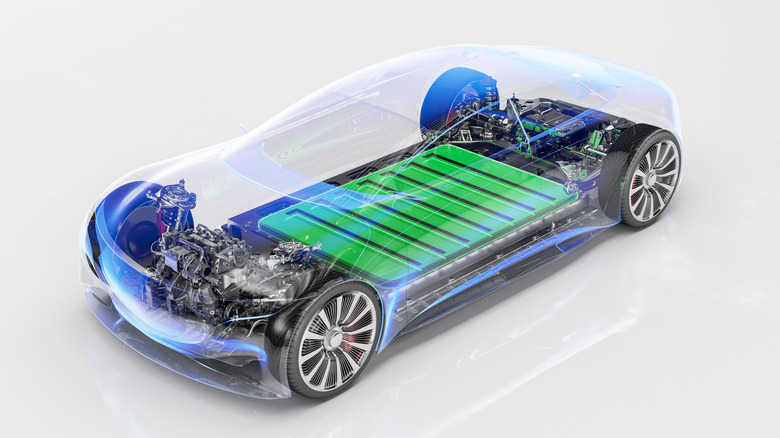

In 2024, the company demonstrated its latest DM-i 5.0 plug-in hybrid platform that delivers a driving range of an astonishing 1,200 miles with a starting price of around $13,000. When it comes to EVs and hybrids, range is a crucial factor. The higher you go, the more appealing it gets. Yet, most carmakers, including BYD and Tesla, only give a surface-level overview of their battery architecture, focusing more on performance gains and than the underlying engineering.

A team of researchers has now given the teardown treatment to Tesla and BYD's flagship battery packs, using everything from pliers and diamond disk Dremels to shielded cables and inert gas disassembly chambers. Taking these batteries apart delivered a few surprising findings. The overarching conclusion was that Tesla is focused more on providing higher performance, while BYD takes an approach that is more cost effective, runs cooler, and provides a longer battery life.

Racing ahead of a hotter Tesla cell

As part of their teardown experiment, the researchers took apart Tesla's 4680 cell and BYD's Blade cell to study their underlying design and features. The conclusion they arrived at was that BYD batteries have superior thermal management, which helps make them more efficient. Tesla's batteries focus more on delivering a higher performance and more energy density, while BYD's battery packs are designed with lowered costs and higher volume efficiency in mind.

The teardown team started by looking at overall battery design. Tesla relies on a cylindrical form factor, while its Chinese rival goes with a blade-like design. As far as energy density goes, Tesla's 4680 cell offered nearly 1.5x higher energy density per weight and 1.8x higher energy density per volume unit compared to BYD's blade cell. However, that output also results in stronger heating. After testing the cell thermal efficiency, the team deduced that in order to maintain the same performance, a system using Tesla's 4680 cells requires twice the cooling capacity per unit volume compared to the one using BYD cells.

That cooling efficiency courtesy of LFP (lithium iron phosphate) chemistry in BYD cells is not only a better choice at reducing the risks of fire safety hazard, but also facilitates faster charging. "Therefore, the LFP electrode design is more favorable for designing a cooling strategy for fast charging," adds the research paper, which has been published in the Cell Reports Physical Science journal. The alternative NMC811 (lithium nickel manganese cobalt oxide composite) chemistry of Tesla's battery cells chases higher performance, but it has also attracted bad press over battery packs catching fire.

A superior balance of cost and longevity

Coming to cost efficiency, BYD's Blade cell was found to be roughly EUR 10/kWh cheaper compared to its Tesla rival. That's primarily because Tesla's battery cell relies on the NMC811 chemistry, which focuses more on extracting higher performance. The BYD Blade Cell, on the other hand, relies on the LFP formula, which helps produce battery packs that are cost effective and offer higher longevity.

The team also mentioned that despite its significantly larger size, the BYD cell has a similar proportion of non-active components like busbars, housing, and current connectors as its Tesla counterpart. The paper further adds that where BYD's prismatic Blade cell involves two extra stages in the assembly, its significantly higher energy capacity per unit means they need to assemble only one-fifth the number of cells compared to Tesla to achieve the same kilowatt-hour output.

Despite these similarities, the brands follow engineering and assembly approaches that differ at fundamental levels, while being sufficiently innovative in their respective domains. BYD scores a meaningful victory by focusing on lower costs and higher battery longevity, both of which are important factors for EV shoppers on a budget. Tesla, on the other hand, goes for a performance-first approach, which is suited for more expensive vehicles. Ultimately, BYD is closer to the democratizing EVs ethos than Tesla, a strategy which also reflects in the former's car pricing as well as wider portfolio.