Cummins 14.3L Ace: The 1,000 HP Combat Engine Designed To Power Tanks

Clessie Cummins founded the Indiana-based Cummins Engine Company in 1919. Since then, the company name has been simplified to Cummins Inc. but still retains a Columbus, Indiana address. However, in addition to its Indiana home base, Cummins operates additional production facilities in North Carolina, New York, across the Atlantic in the U.K., and further east in India.

While the Cummins 5.9L and 6.7L Turbo Diesel engines may be the most widely known versions due to their use in Dodge Ram pickup trucks, some semi trucks also use Cummins engines. In addition, Cummins produces diesel engines for use in agriculture, mining, construction, and even military applications.

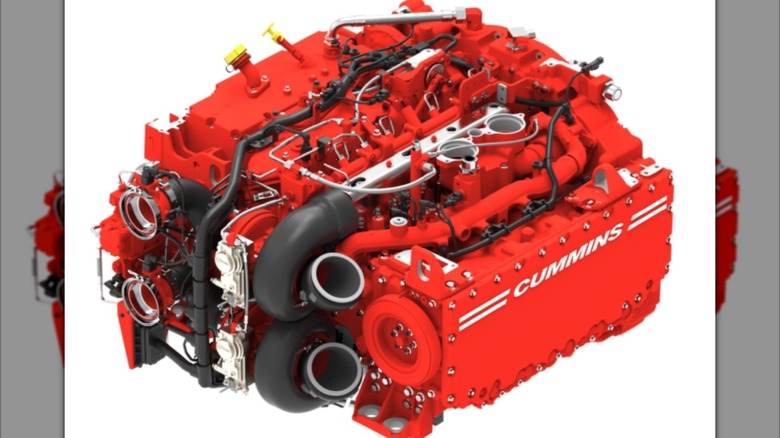

Most Cummins engines feature a four-stroke design, but Cummins has experimented with two-stroke diesel engine designs for use in its Indy 500 racing effort in 1934. The Cummins two-stroke diesel engine has come full circle with the development of the 1,000-horsepower 14.3L Advanced Combat Engine, known as the ACE, designed in conjunction with Achates Power and the U.S. Army for use in infantry vehicles and tanks.

What are some key specs of the Cummins 14.3L ACE?

In addition to the 1,000-horsepower output of the 14.3L ACE, the two-stroke four-cylinder diesel produces 2,424 lb-ft of peak torque. Creating that much power is impressive, but one of the ACE's most desirable traits is its compactness. The Cummins four-cylinder 14.3L ACE measures 48 inches long, 43 inches wide, and 23 inches tall, occupying a volume of roughly 27.5 cubic-feet.

For comparison, the Cummins 14.8L V903 produces up to 760 horsepower and 1570 lb-ft of torque but measures 56.5 inches long, 35.1 inches wide, and 35.6 inches tall. However, the ACE, at 3,571 pounds, weighs nearly 1,000 pounds more than the 2,580-pound V903.

One of the ways Cummins coaxes that much power from the ACE's small package is to use a combination of turbocharging and supercharging. Cummins describes the air intake system used on the ACE as a combination of its HE500 variable geometry turbocharger and a gear-driven supercharger. An aluminum jacket water-aftercooler and oil coolers combine with a gear-driven water pump to efficiently transfer heat away from the system while under power.

What's special about the Cummins Advanced Combat Engine?

The fact that the Cummins ACE is a two-stroke diesel engine gives away the fact that it doesn't have a complicated valve train with camshafts, timing chains, rocker arms, pushrods, or valves that could fail under the engine's predicted operating conditions. However, one of the most unique aspects of the four-cylinder Cummins ACE is the presence of its eight pistons.

In addition to the turbo and supercharger combo, the two-stroke Cummins ACE uses opposed-piston architecture to create an engine with increased power density. The design is also fuel efficient and features low levels of heat rejection, retaining heat used to enhance combustion efficiency.

An opposed-piston engine is fairly simple, at least as far as its operation is concerned. Two pistons, one at each end of the cylinder, are pushed by their respective crankshafts to compress the injected fuel and forced-air mixture between them, where it is ignited to produce the power stroke. At the end of the power stroke, spent exhaust gas is evacuated, and fresh air is inducted through separate ports in the cylinder walls as the cycle starts over.