3 Things You May Not Know Cummins Makes For The Military

Cummins has been around since 1919 and builds everything from engines to transmissions in its various plants around the world, including three plants in the United States and one in the United Kingdom. Being in business for more than a century gives a company plenty of time to diversify its portfolio. Compounded with being a powertrain company best known for its diesel engines, including its 6.7-liter turbo diesel engine, Cummins has plenty of practical applications to dabble in. One such endeavor is taking on military contracts.

The military needs mechanical components of all kinds for its aircrafts, various marine vehicles, and, of course, land vehicles, putting companies like Cummins in a unique position to branch out beyond commercial products. The brand's dependability makes it a go-to for not just the U.S. military, but also militaries around the world. No matter which military it is, they all require durable and reliable components, something Cummins has a reputation for. Cummins has built a surprising amount for the military.

Power generators

The military heavily relies on getting power to its bases, especially when it's a forward-operating base built in the middle of a conflict. In the modern day, power is essential for more than lighting and simple communications. There are computers, satellite terminals, displays, climate control, and other systems dependent on electricity for power. In the 100-plus years Cummins has been in business, the demand for power has gradually increased. Its solutions have grown with that demand. Cummins manufactures power generators capable of keeping anything from a large airfield to a medium-sized mobile base operational.

When the U.S. military makes a base in a foreign country, referred to as a microgrid, it relies solely on diesel-powered generators. Cummins offers two solutions to the military when it needs a generator. There's the Rugged Mobile Power (RMP) unit that's essentially a giant green box that supplies power. It's not anything like Harbor Freight's Predator 3500 or Predator 5000 either. The RMP builds on Advanced Medium Mobile Power Source technology and comes in a variety of models that offer a wide range of power output from 5kW to 60kW. When the military has an airfield to power, it needs something a little more robust.

That's where the DQBPU model comes in. It's a generator mounted to a trailer that provides 800kW and utilizes a variety of fuel sources, including JP-8, JP-5, Jet A, and DF 1, 2. It operates in temperatures ranging between 25 to 140 degrees Fahrenheit, meaning there are few places it won't work.

Engines for boats

Cummins is a big name in the powertrain industry used by some of the largest automotive brands. Dodge has been using Cummins diesel engines in its trucks since 1989. When it comes to military applications, though, Cummins also builds engines for maritime use. Indonesia is a giant archipelago where many of the nation's residents make a living on the water or utilize the waterways in some way. The Indonesian government patrols the waterways with search and rescue vehicles to keep all the professional mariners safe. Each of these vessels is equipped with three V-16 cylinder KTA50-M main engines that can get up to 1,875 horsepower and 20 knots.

When the U.S. Army sought out a bid for a new bridge erection boat (BEB), a function the Army has used since World War II, Birdon America, a subsidiary of Birdon Australia, won the bid. The Army ordered 400 BEBs, and Birdon turned to Cummins for propulsion. Cummins installed twin QSB6.7-liter engines on each BEB. These 6-cylinder engines produce up to 550 horsepower and can get the BEBs to exceed 25 knots.

Cummins equips the Mauritius National Coast Guard with a pair of QSC 8.3-liter engines for each of its boats used for surveillance and search and rescue. Each QSC 8.3 engine delivers as much as 600 horsepower. They operate in conjunction with Rolls Royce water jets that give the boats a top speed of 35 knots.

Military-grade powertrains and drivetrains

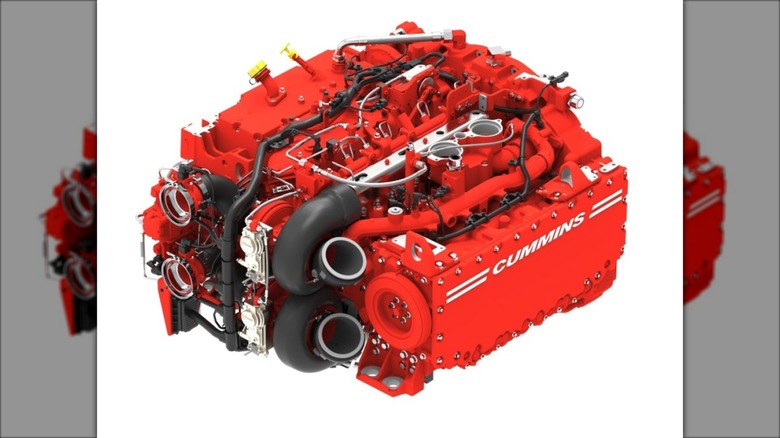

Militaries of every nation use a wide variety of land vehicles. Cummins has been supplying militaries with drivetrain and powertrain components since its inception. In the powertrain department, it has what it calls the Advanced Combat Engine, or ACE, for those exact vehicles. Cummins boasts on its website that this engine "is ideal for new or repowered combat vehicles where mission effectiveness, maneuverability and survivability are key objects." It's a compact four-cylinder, two-stroke 14.3-liter engine that can deliver up to 1,000 horsepower with its super and turbocharging capabilities.

The U.S. Army tested the ACE in the Advanced Mobility Experimental Prototype (AMEP) at its Yuma Proving Ground in Arizona. In Yuma, the ACE was placed in a Bradley A4 Fighting Vehicle and competed against a Bradley without the Cummins engine to see how it compares. In a straight away, the AMEP outran its counterpart and successfully completed a series of obstacles that Fighting Vehicles are expected to overcome with ease, including climbing a 30-inch step, traveling on a 60% grade, and towing a Dyno trailer.

The combat engine is built to withstand all desert conditions any military might find itself in and accepting every kind of military fuel as well, including JP-8, JP-4, DF-1, DF-2, DF-A, F-24, and HVO. When it comes to drivetrain, the century-old company manufactures the ProTec axle series that's rated for a gross axle weight of up to 126,000 pounds. Beyond that, Cummins offers a variety of drivetrain components that governments can use on many of their vehicles.