Everything To Know About Aircraft Engine Maker DeltaHawk

DeltaHawk is an aircraft engine manufacturer based out of Racine, Wisconsin. It doesn't have the name recognition as other aerospace contractors like General Electric or Pratt & Whitney, which changed air travel forever with its Wasp engine, but DeltaHawk sure would like to do something similar. DeltaHawk has a unique, proprietary engine design that's protected by a series of patents and was built with pilots in mind. The company currently has three engines it's building out of its state-of-the-art 85,000 square foot facility in Wisconsin. The DHK180A4, DHK200A4, and DHK235A4 all produce their maximum power output at 2,600 RPM.

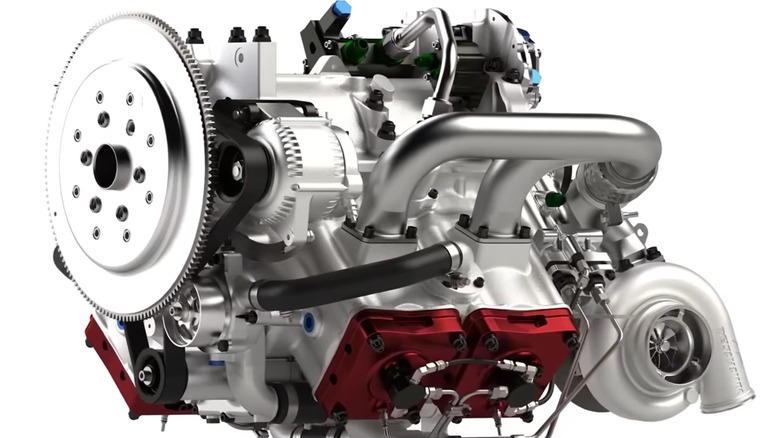

These engines produce 180, 200, and 235 horsepower, respectively, with an inverted V4 design that uses a four independent pump line system for direct fuel injection. The company prides itself on bringing cleaner engines to market that cut down on carbon emissions while also being easy to use and maintain. Since the DHK series engines don't use an overabundance of components — there's no gearbox nor a valve train — it's easier to access the pistons.

DeltaHawk has been developing its engine for over 25 years and things were a little touch and go for a bit, but now it has a product it believes can be applied to a variety industries, including government, experimental, and hybrid aircraft.

DeltaHawk had an uphill battle since its inception

Doug and Diane Doers and John "JP" Brooks established DeltaHawk as a company in 1996 with the intention of developing an entirely new compression engine. The founders wanted to take advantage of the newest cutting-edge propulsion technology to raise the bar in piston-aircraft power. Doug and JP were both veteran pilots, while Diane had a background in business. Doug and JP wanted to use their experience in the cockpit to design an efficient engine that other pilots would be proud to use.

Two years after the company's founding, it created its first prototype engine and installed it on a Velocity RG airframe. The company secured low-interest financing from the state of Wisconsin in 2011, but kept its operation small. Nearly two decades after DeltaHawk was founded, the company got some help from private investors. Christopher Ruud took over as CEO in 2015 when he became the majority shareholder. In 2018, DeltaHawk initiated testing on its DHK-series engine for FAA certification, and by 2019 it had grown to 60 employees.

By the time 2023 arrived, the DHK series had earned FAA certification and DeltaHawk had secured patents in Europe, China, and the United States. With testing complete, DeltaHawk expects its first engine deliveries to come some time in 2025.

DeltaHawk's engines are future-proof and economical

DeltaHawk prides itself on making its engines available to a wide variety of customers no matter where they are in the world or what kind of fuel they prefer to use. Its engine is certified to burn Jet A and Jet A-1 fuel. It will also burn JP5, JP8, and #2 Diesel, as well as sustainable aviation fuel (SAF), which is an alternative fuel source derived from non-petroleum feedstocks. Around 140 airports worldwide distribute SAF and more than 360,000 commercial flights have used it. Virgin Atlantic championed SAF back in 2023, flying across the Atlantic Ocean using only this alternative jet fuel source. The use of SAF has contributed to DeltaHawk's engines burning between 35% and 40% less fuel than conventional aircraft engines.

The European Union has approved aggressive new emissions rules that requires 63% of aviation fuel to be SAF by 2050. The United States is expected to follow suit, and DeltaHawk is prepared. The caveat with SAF, however, is its cost. As of 2023, traditional jet fuel cost roughly $2.85 per gallon while SAF came in at $6.69 per gallon. DeltaHawk is merely future-proofing its product in anticipation of SAF becoming cheaper, and maybe even the new standard for jet fuel. At 2,600 rpm, DeltaHawk's engines burn between 10.8 and 13.1 gallons of fuel per hour of flight. Pilots can cut consumption to between 7.3 and 10.2 gallons per hour by running the engines at 2,200 rpm.