4 Space Projects You May Not Have Realized Kawasaki Is Involved In

Kawasaki has made a name for itself, making some of the best two-wheelers out there, especially the Ninja series of sports bikes. It would, however, surprise many fans that the parent company is a conglomerate involved in businesses ranging from aerospace and rail transportation to submarines and energy solutions. In fact, the company is also deemed a respected player in the robotics business, offering solutions for the healthcare, construction, petrochemical, food, and electronics industries.

Take, for example, the Boeing 787 Dreamliner passenger plane, which had the forward section of its fuselage developed and produced by Kawasaki Heavy Industries. Interestingly, Kawasaki Heavy Industries also has a long and prestigious association in the space industry. Kawasaki's endeavors began decades ago, and today, the company claims that it "contributes to space systems, including the payload fairings for H-IIA and H-IIB rockets." That is impressive in itself, but the company has gone as far as designing satellites tasked with removing space junk.

Among the notable business engagements is the H-2A expendable launch system that has handled numerous projects for the Japan Aerospace Exploration Agency (JAXA) and also played a pivotal role in the Emirates Mars Mission that took off in 2020. In fact, the company's aerospace division has been one of the key players in JAXA's space missions, and it continues to work on the development of the next-gen H3 launch vehicle for the country's space agency. There's the Kibo module on the space station, which has served as the home for not only astronauts but also the test bed for a wide range of scientific microgravity experiments and satellite launches.

Kibo

Kawasaki was one of the core partners involved in the development of Kibo, a science module installed aboard the International Space Station (ISS) by Japan's space agency. In particular, Kawasaki was responsible for developing Kibo's air conditioning system, airlock kit, Exposed Facility Berthing Mechanism (EFBM), and the Exposed Experiment Handrail Attachment Mechanism (ExHAM) that enables scientists aboard the Kibo to conduct scientific tests. Notably, Kibo is the largest component of the space station, and it is also Japan's first manned facility in space for long-term astronaut activity.

Operational for over a decade and a half, and responsible for more than 350 satellite deployments, Kibo consists of four core elements, including a robotic arm called the Japanese Experiment Module Remote Manipulator System (JEMRMS) that is remotely operated by a ground-based team. "Among the experiment modules on the ISS, only Kibo has its own storage compartment," says JAXA. Linked round-the-clock with teams at the Tsukuba Space Center, the module's assembly took three Space Shuttle missions, beginning in 2007.

As far as scientific experiments go, astronauts have managed to grow high-quality protein crystals on Kibo, germinate rice in space to study their cell walls, create large single crystals of high-performance semiconductor materials, and detailed X-ray observations, among others. There are a total of 12 ports on the platform for mounting experimental equipment. On Kawasaki's end, the biggest contribution went to the Exposed Facility, a multi-purpose experiment platform suited for scientific tests and observations that require exposure to the vacuum of space.

H-2A launch vehicle

Kawasaki notes that it is "in charge of designing and of payload fairings for H-IIA" launch vehicle in addition to the H3 and Epsilon S variations. Beginning its operations back in 2001, the H-2A (also listed as H-IIA) is an expendable large-sized mainstay rocket that has been in continuous service for injecting satellites and experimental probes by the JAXA. Standing at 53 meters tall, it is a customizable vehicle that consists of two solid rocket boosters.

Based on the mission requirements, it can be fitted with an extra pair of SRB-A type boosters to enhance the launch capability, such as the Castor IVA-XL solid strap-on booster motors provided by Northrop Grumman. Propelled by liquid hydrogen and liquid oxygen, it has been predominantly used in H2A202 (two rocket boosters) and H2A204 (four rocket boosters) variations. There was once an even heavier version — called H-IIIA — in operation, which relied on a combination of liquid hydrogen and oxygen. Kawasaki, for its part, developed the four-meter single-payload fairing for the H-2A launch vehicle.

"Since delivering the first payload fairing for the H-II launch vehicle in 1993, Kawasaki has developed and manufactured a variety of payload fairings for a total of 25 H-IIA launch vehicles," says the company. Notably, Kawasaki is the sole maker of payload fairings in the country. Among the most notable accomplishments of the H-2A launch vehicle was the Hayabusa 2 mission, which made contact with the Ryugu asteroid in 2019 and returned with samples that are now in labs across the world.

Unmanned Space Experiment Recovery System (USERS)

The structure and heat shield system aboard the Unmanned Space Experiment Recovery System (USERS) mission was developed by Kawasaki. Launched aboard the H-IIA Launch Vehicle in 2002, the USERS mission carried experiments tasked with scientific microgravity assessments and was successfully recovered in 2003. Developed by the non-profit Institute for Unmanned Space Experiment Free Flyer (USEF) and supported by the country's Ministry of Economy, Trade and Industry (METI), the core goal of the whole project was to develop a self-return system and an unmanned on-orbit experiment infrastructure, but also found utility as a template for space debris mitigation efforts.

Among the main payloads was the Super-conductive bulk Material Processing experiment (SMAP), which aimed to test the functioning of a large-size bulk super-conductive magnet, a tech that finds utility everywhere from medical imaging, spectroscopy, and particle accelerators to the budding field of fusion reactors and magnetic levitation trains. The experiments were accomplished within the Super-conductive bulk processing Gradient Heating Furnace (SGHF) installed in the Recovery Vehicle (REV), which is the recoverable segment of the RE-entry Module (REM).

Kawasaki designed and supplied the heat shield system for the REV phase. It seems Kawasaki's contributions did their job, well. "The quick review indicates that the function of the heat shield was complete with the results that there is no sign of hot gas leak on the inner skin surface and inside structure temperatures were lower than the design requirement," says a USEF paper presented at an esteemed astronautical conference in 2003.

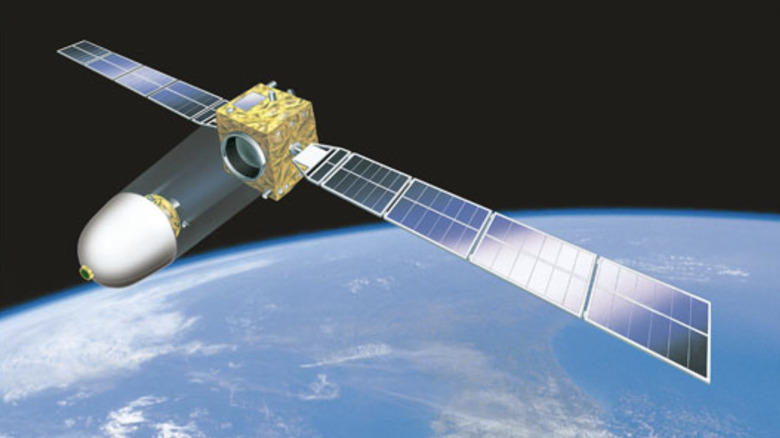

Space Debris Removal Satellite

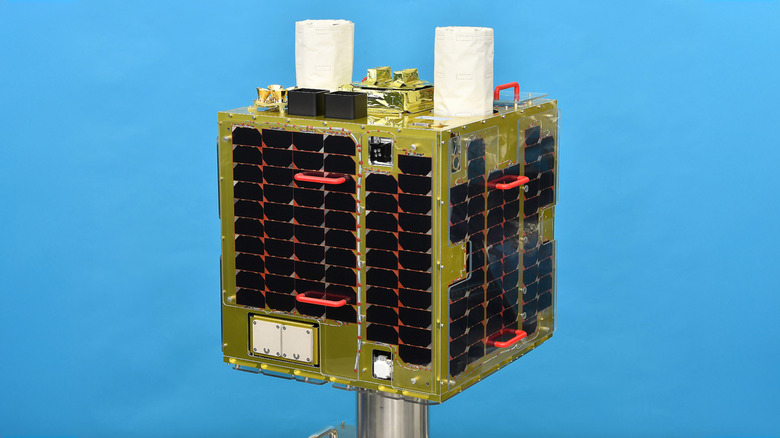

Kawasaki is also tied to projects that aim to solve the nagging space debris problem via in-orbit solutions. Among them is the Debris Removal Unprecedented Micro-Satellite (DRUMS), which was launched by JAXA aboard the Epsilon rocket vehicle in 2021. "We have developed our own satellite, DRUMS*, and successfully demonstrated its technology in orbit," said Kawasaki, in the wake of the mission deployment.

With a volume profile of 600 mm x 600 mm x 800mm and tipping the scales at just under 62 kilograms, the first DRUMS test was aimed at demonstrating the feasibility of such an approach to solving the space junk problem. It was armed with a vision-based navigation system, which measured the relative distance between the Active Debris Removal (ADR) satellite and the junk floating around in the orbit.

"What is also significant for our company in this demonstration is that it is the first time that we have developed an entire satellite. Having a satellite that we developed in-house function properly in space is another major theme, along with the demonstration of the debris capture mechanism," members of the Aerospace Division at Kawasaki told JAXA (translated from Japanese).

The main element of the kit is an extendable boom, responsible for capturing the debris in the vicinity. As per a technical paper submitted by experts at the Kawasaki Heavy Industries, the microsatellite would lock the target using its visual sensor, and once it reaches within a two-meter reach of the debris, the extendable boom would be released for object capture.