Who Makes PAR Racing Engines & Where Are They Built?

Scott Duggins started building car engines in 1984 alongside his father. They worked together offering a mix of engine rebuilds and overhauls for their customers' daily drivers as well as supplying race engines for competition use. In an interview with Engine Builder, Duggins stated that, following the retirement of his father, PAR (Performance Automotive Racing) Racing Engines diverged into building race engines full time in the same shop in Spartanburg, South Carolina, where Scott first started.

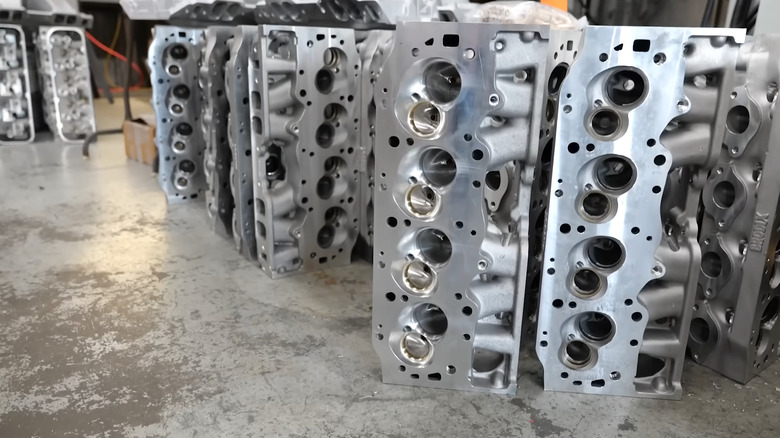

Duggins says the equipment used by PAR Racing Engines has evolved over the years from the basic tools and supplies needed to rebuild an engine to the high-tech 5-axis CNC (computer numerical controlled) machines it uses today. The newer machines allow buying raw cylinder head and intake manifold castings in bulk and applying custom PAR-formulated port grinds to them for specific customer requirements.

In addition to CNC porting, Duggins purchased a HAAS CNC machine to make a lot of the smaller parts the company used to source elsewhere. While the cost of those parts was minimal, supply chain lead times up to five months were impacting PAR's ability to produce the 250 to 300 engines PAR sells annually.

What makes PAR Racing Engines special?

Duggins can use the specialized machines to probe intake and exhaust ports he's ground by hand and replicate them using CNC technology in less than half the time it takes to do it by hand. A key benefit to PAR customers is the reduced turnaround time. Before the CNC machines, it could take six to eight months to work with a cylinder head supplier to get custom castings, do the porting, complete testing, and get it on the racetrack. With the ability to digitize the design, the process can be completed in a week.

PAR Racing Engines utilizes a long list of premium suppliers for upgraded components that make more horsepower possible. Included on the list is Brodix, a supplier offering precision cast cylinder heads, engine blocks, and intake manifolds. Callies, another well-known name, supplies forged and billet crankshafts and connecting rods. There are too many to list, but other company highlights include Holley, Crane, Isky, Comp Cams, Diamond, JE, Wiseco, and MSD Ignition.