Why Do Trucks Use Air Brakes And How Do They Work?

Many of the larger vehicles on our roads have one intriguing thing in common: They can make sudden, loud, gas-escaping hissing noises. These noises, admittedly, have made this writer jump — on more than one occasion — while passing close by, but it's for a vital cause. Semis and similarly sized vehicles, like buses, have air brakes, and that sound is made by the safety valves resetting the air pressure after use.

True air brakes are largely unheard of in cars, though McLaren boasts that its unique and super pacey Speedtail is equipped with ailerons that "extend at high speed to provide balance and provide airbrake function." It's difficult, however, to compare the sleek Speedtail to a heavy, hard-working truck or bus: While the former's ailerons are designed to ensure smooth airflow across the vehicle's body and cut the effects of drag, a truck primarily uses air brakes to provide the braking force required to help drivers bring their heavy and often heavily laden steeds to a stop.

There are other advantages to using an air-brake system as well. Here are the reasons why air brakes are used in big trucks, as well as how they work and how they differ from the conventional hydraulic brake systems typically found in cars.

Why trucks use air brakes

Truckers have very different driving experiences compared to those who drive other autos. Though driving a lightweight vehicle is no walk in the park, taming a laden truck is something else entirely. The very fact that 80,000 pounds is the maximum gross vehicle weight allowed by Federal law demonstrates just how big the trucks on U.S. highways (as well as around the world) can become.

With such heavy machines, considerable force is needed to safely stop them, so heavy-duty brakes are employed. Operating at a pressure range of typically between 100-120 psi, air brakes allow the driver to stop a large vehicle, without requiring the higher level of force that an equivalent hydraulic brake system potentially needs.

Additionally, air brakes are typically chosen for larger vehicles for safety reasons. As they can cause significant danger to their occupants, potential loads, and fellow road-goers, it's imperative that they use the most reliable braking system they practically can. To that end, air brakes are typically considered to be the best option for larger trucks and buses, primarily due to differences in the way that air and hydraulic brakes work.

The basics of the triple-valve air brake system

In a hydraulic brake system that's typically found in smaller vehicles, brake fluid is the key to stopping those vehicles. This liquid within the brake lines is pressurized by the action of the pistons when the brake pedal is depressed. The brake fluid carries that pressure to the brakes themselves, allowing the system to grasp the rotors and stop the forward momentum through friction.

One issue with this system is that it's almost entirely reliant on that brake fluid to function, meaning that it's crucial to consult your car's manual for the right type of brake fluid and to monitor, maintain, and change your brake fluid as needed. This is not a concern with air brakes, which require no fluid but rather a gas: our ever-present friend, air.

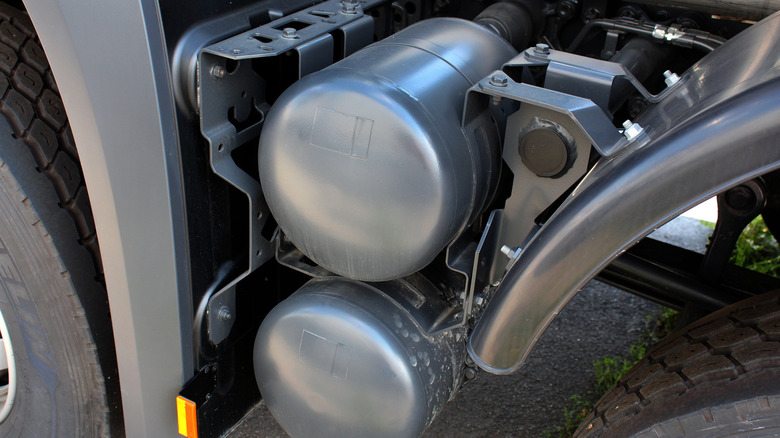

The basic principles of an air brake revolve around the system originally developed for trains by engineer George Westinghouse in 1869. The innovation here was that the air deactivates the brakes. That air is stored in tanks, and while the pedal ultimately leads to the rotors bringing the vehicle to a halt in the same way as hydraulic brakes, the process through which it does so differs significantly. Let's see how the most popular variety of air brake, the foundation brake system that uses an s-cam, works.

Disk brakes, drum brakes, and emergency brakes

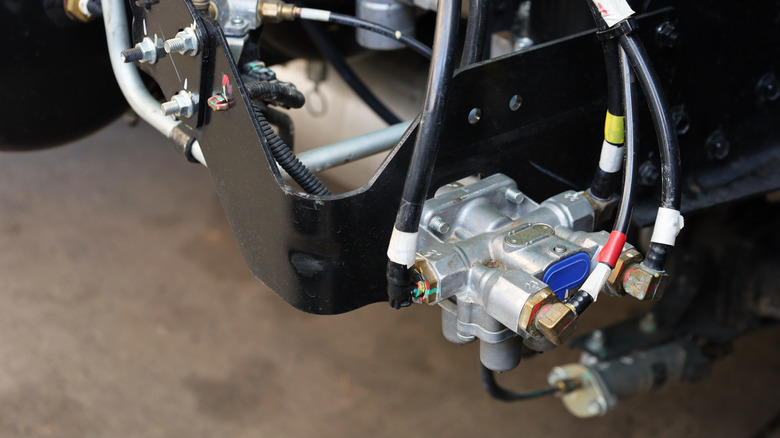

The basics of an air brake system are easy enough to grasp, but a complicating factor is that there are disk brake and drum brake varieties. In disk air brakes, the brake chamber's pushrod is manipulated by air pressure acting on the diaphragm, and it's this movement that causes the interaction between the disk and all-important brake pads housed inside the caliper. In this case, the energy required to bring the vehicle to a halt is the heat that results from their contact with the disk.

Air drum brakes lack the caliper that is so critical to the action of disk brakes. Instead, they revolve around (not literally) the drum that is fixed to the truck's wheel. Air from the compressor passes from the air tanks when the brake pedal is used. This allows the s-cam to rotate in response to the camshaft, thereby causing the brake shoes to press against the drum. It's like a more practical and physically possible take on Fred Flinstone's feet.

Though air brakes are generally the safest method of stopping such hefty vehicles, another failsafe is also mandatory. Parking brakes and emergency air brakes work in a rather different fashion to the standard brake system in a truck. They're spring-loaded, and designed to function in automatic and manual manners should issues arise with the primary brake system. In this case, air pressure holds the springs in place, so a failure of that pressure will activate them.

The potential shortcomings of air brakes

Air brakes are self-powering, to a degree, as the governor generally built into the air compressor ensures that the right amount of gas is available in the tank(s), and that the pressure remains where it should be. Air, of course, is easy enough to refill as there is always a ready supply, and the compressor's filter helps see to that. The action of moving air does leave the system with some inherent flaws, though.

Owing to the need to fill in this way, air brakes take some time to engage and stop the vehicle when deployed. This period, called brake lag, contributes to the total time and distance it takes the vehicle to stop, approximately an extra 32 feet when traveling in dry conditions at 55 mph, according to the State of California Department of Motor Vehicles.

While a reliable choice for trucks, there's no mechanical device in existence that's immune from errors and malfunctions, and the important thing is to minimize the danger that can occur. The Westinghouse-derived system has an invaluable safety feature built in. With this system, loss of air pressure won't prevent the driver from applying the brakes, but prevent them from releasing the brakes. A broken-down truck on the highway is an obstacle no commuter wants to face when running late, but consider the alternative. The fact that this system can dramatically cut the threat of that scenario has surely saved many lives on our roads.