The Mystery Behind Chevy's V8 Distributor Design

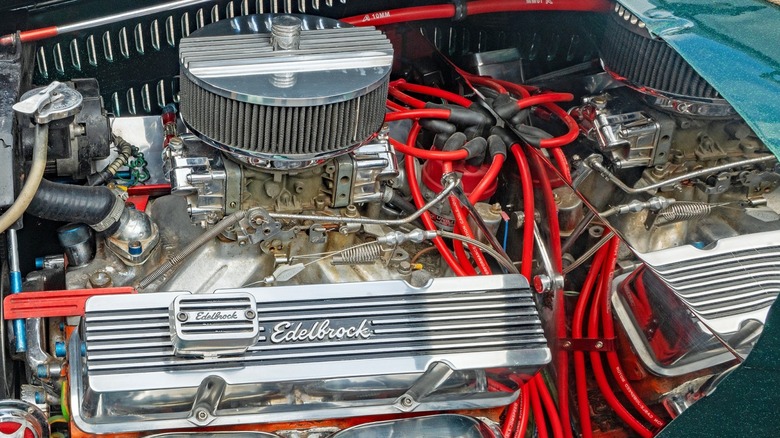

If you've ever leaned over the fender of an old Chevy, timing light (one of the automotive diagnostic tools to add to your DIY collection) in one hand and a long extension on a ratchet wrench in the other as you attempt to tighten the distributor clamp at the back of a Chevy V8 while its running, you've probably asked yourself, "Who thought that was a good place for the distributor?" Back before the advent of the Engine Control Module (ECM) we performed such feats to adjust the engine's ignition timing.

The rear-mounted distributor location wouldn't have been so bad, except the timing light used electrical leads attached to the battery and one to the number-one spark plug wire, and had to shine on the timing tab on the front of the engine while you turned the loosened distributor ever-so-slightly to get the desired timing. Then you had to tighten the distributor clamp without bumping it out of time.

Other automakers, like Ford, Chrysler, AMC, and even some General Motors Divisions, gravitated toward distributors placed at the front of their V8 engines, but Chevy stayed true to the rear placement for decades. This leads us back to our original question, "Who's bright idea was this?"

Why would Chevy engine designers put the distributor at the back of the engine?

The truth of the matter is that the designer of the first Chevy V8 is long gone, as are any official reasons for the rear mounted distributor placement. But there are rumors, such as specific car model requirements, production costs, and protection from weather, but nothing concrete. So, let's look at some facts.

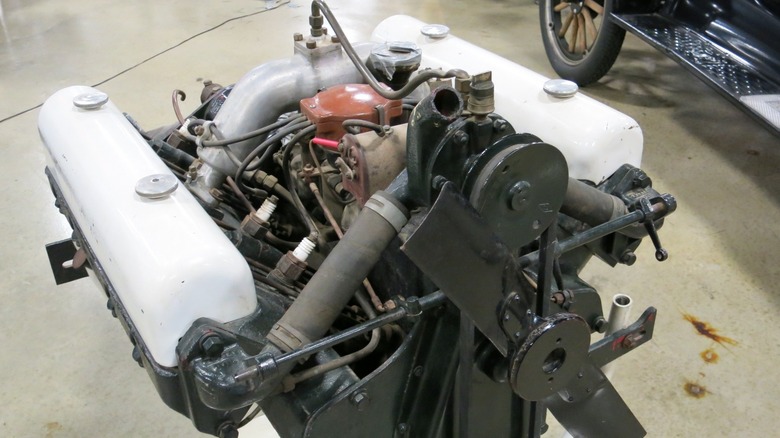

Chevrolet's first V8 engine, the 288-cubic-inch Series D, came out in 1917 with a mid-engine distributor location. That early V8 was discontinued in 1919 after being placed in about 3,000 cars. Chevrolet's next foray into V8 power was the founding member of what would become a leading engine design, the 265 cubic-inch small-block V8. Like the other small-block Chevy engines that would follow, the 265 featured pushrod actuated overhead valves, 4.40-inch on center cylinder spacing, and a distributor located at the rear of the engine.

The most likely reason for the rear mount location is protection from water intrusion. However, moisture trapped in the distributor cap, fouling contact points and causing corrosion, was an ongoing issue. So much so that the Gen-II Chevy small block's Opti-Spark distributor featured vacuum vents designed to remove moisture from the system. While the rear-mount position may not have prevented moisture problems, once the design was in place there wasn't much reason to change it.

[Featured image by CapCase via Wikimedia Commons | Cropped and scaled | CC BY-SA 2.0]

Did any other automakers use a rear-mount V8 distributor?

Chrysler introduced its first-generation Hemi engine in 1951. In addition to the now-legendary, hemispherical combustion chamber design, the 331-cubic-inch FirePower V8 featured a rear-mounted distributor. However, by the time the second-gen 426 Hemi came around in 1964, the distributor location was moved to the front of the engine.

The Ford Y-block was another early V8 engine introduced in the early 1950s with its distributor mounted at the rear of the engine. The Y-block's claim to fame, and namesake, was the extended length of the skirt at the bottom of the block. Typical V8 engine block castings only extended downward to about the centerline of the crankshaft, but Ford's Y-block deep-skirt design offered a more rigid platform to stabilize the crankshaft.

While most automakers used distributors located at the front of the engine, Chevy's rear placement endured for decades. Although it's not the most convenient location when adjusting ignition timing, it's one of the most recognizable features of the Chevy V8.