How Reliable Are 6.4L HEMI Engines? Here's What Owners Have To Say

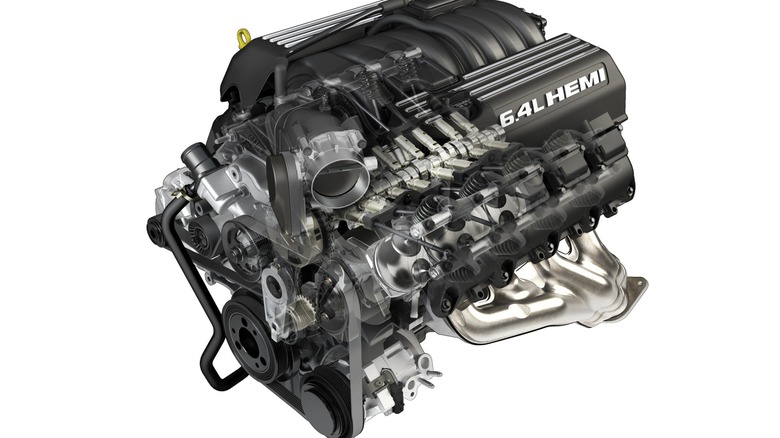

You can find the 6.4L, or 392, HEMI under the hoods of several models of cars, SUVs, and heavy-duty pickup trucks from Chrysler, Dodge, Jeep, and Ram. The first Gen III 6.4L HEMI variant, introduced by Chrysler's Street and Racing Team (SRT) in 2011, was designed for sports car performance to power SRT-badged models like the Chrysler 300, Dodge Charger, Challenger, Durango, and a few Jeep SUVs.

It took a couple of years to roll out the SRT 6.4L HEMI across the lineup, following which Ram trucks adopted a slightly less powerful 6.4L HEMI for use in its heavy-duty 2500 and 3500 pickup truck lineup and larger chassis cab models. The pickup truck version launched in 2014 with 410 horsepower and 429 lb-ft of torque, while some of the chassis cab trucks saw lower power ratings.

With over a decade of service in all kinds of vehicles used for a multitude of tasks ranging from racing to rock climbing and towing substantial loads, the 6.4L HEMI has proven itself to be a reliable work-horse for many. Owner reports exceeding 150K miles are common, with some approaching 200K. The most common owner reported 6.4L HEMI engine problems being the troublesome "HEMI Tick" and the associated valve train failure.

What is HEMI Tick?

The main cause of HEMI Tick is the failure of Chrysler's Multi-Displacement System or MDS controlled valve train. Most, but not all, 6.4L HEMI engines use MDS to deactivate four of the eight cylinders whenever the engine is experiencing light load demands, like coasting downhill or cruising along a flat highway. Deactivating half the cylinders reduces pumping losses by keeping the deactivated cylinders' valves closed after the power stroke, using the trapped exhaust gas as a type of compression spring to conserve energy.

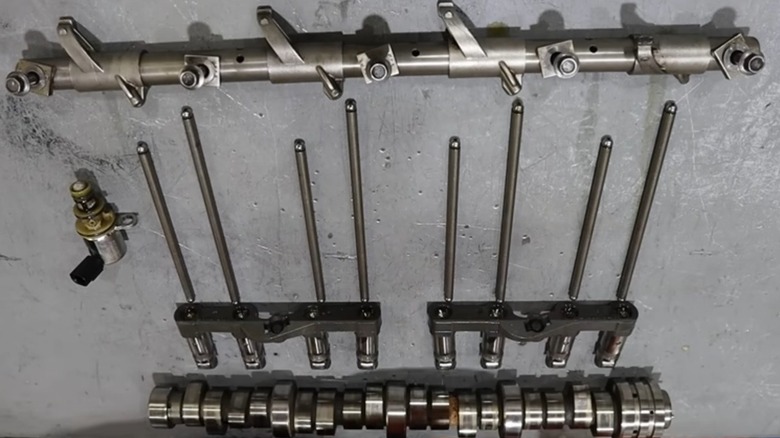

The system uses solenoids to control the flow of pressurized engine oil to the roller lifters. Each MDS lifter deactivates with precise timing, allowing it to follow the camshaft lobe using spring pressure, but not with enough force to open the valves located in the cylinder heads. While the timing and mechanical process required to make MDS work is an engineering marvel, the problem starts with the limited oil flow in the system's off position.

Until the MDS is activated, oil-flow to the rocker arms, pushrods, and lifters is restricted by the MDS solenoids. This means that anytime the engine is left idling, or working under a load, the engine's valve train components, namely the roller lifter bearings, are not getting the full complement of engine oil available. Once the roller bearings fail, or if the internal lifter-deactivation mechanism fails, the lifter will make an audible tick when contacting the camshaft.

What is the best way to avoid HEMI Tick?

The best way to minimize the chances of HEMI engine lifter failure and the dreaded tick is to minimize the amount of time it's left idling and performing oil changes at prescribed intervals or before. We've already covered the restricted oil flow caused by the MDS at engine idle, but clean engine oil, of the proper type and viscosity, helps keep the lifter deactivation mechanism operating properly.

Once a lifter begins to fail, even before the tick becomes audible, minute metal shavings begin circulating with the engine oil, leading to more damage and fouling more MDS lifters and other components. Even with proper maintenance, including replacing affected components with new versions under factory warranties, some 6.4L HEMI owners still experience problems.

It was reported of a class action lawsuit with three HEMI owners seeking damages caused by the HEMI Tick. Alleged damages include reduced values of affected vehicles, safety concerns of stalled HEMI engines causing an accident, and the potential $15K HEMI engine replacement cost. In addition, the plaintiffs claim warranty repairs of the existing HEMI engine in their vehicles, including replacing camshafts and valve train components, failed to address other damage within the engine or the recurring nature of the valve train failures.