How To Prevent (And Clean) Carbon Buildup In Engines

While port injection is still the most common form of electronic fuel injection, gasoline direct injection is quickly starting to replace it since it provides better fuel atomization, decreased emissions, and cooling properties. Despite the benefits that direct injection holds over port injection, it has a few downsides too, with one of the most significant being increased carbon buildup.

Carbon buildup is a collection of residual carbon compounds that form when not all of the fuel injected into the combustion chamber is combusted completely. Carbon buildup is more common in direct-injection engines than in port-injected engines for one simple reason: Direct injection systems inject fuel directly into the combustion chamber, while port injection systems inject fuel behind the engine's intake valves allowing the passing air-fuel mixture to clean the valves of carbon buildup. Since fuel doesn't pass over the intake valves in direct-injected engines, carbon builds up quickly on the valves and injectors, clogging the injectors and preventing the intake valves from operating correctly. Some manufacturers are now implementing dual-direct and port injection systems in their vehicles to combine the benefits of both systems and limit carbon buildup.

While there isn't a way to prevent carbon buildup completely, there are ways to slow its progress including staying on top of regular vehicle maintenance, using high-quality fuel, and using fuel injector cleaner. It is also possible to get rid of carbon buildup by manually cleaning the valves with a solvent and scraping tools or walnut media blasting.

How can you prevent carbon buildup?

You can limit carbon buildup by staying on top of engine maintenance and paying special attention to oil and spark plug change intervals. Oil maintenance is a big deal when it comes to preventing carbon buildup, as using inferior-quality oil or failing to change it within the recommended interval can cause the oil to break down and accumulate on intake valve stems, leading to buildup. Some oil is specifically made with detergent to reduce the change of carbon buildup.

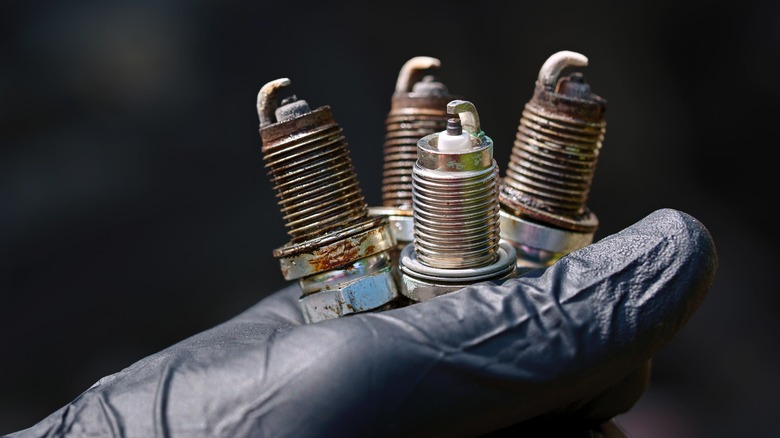

Changing your car's spark plugs at their recommended interval also plays a role in mitigating carbon buildup, as aged or damaged plugs are less effective at combusting fuel, leaving unburned gas in the combustion chamber to harden into carbon buildup.

Fuel quality is another major consideration when it comes to limiting carbon buildup. Direct injection systems rely on extremely high-pressure fuel injectors to finely atomize the fuel entering the combustion chamber. For that process to work, the injectors need to stay incredibly clean and free of contaminants. Low-quality fuels can introduce contaminants into the fuel injectors, interfering with their atomization patterns, causing them to flood the cylinders with fuel, and leading to carbon buildup. That's why it's critical to use not only high-quality fuel, but also the correct octane fuel for your engine. In-tank injector cleaners can also help prevent carbon buildup by clearing out blockages or contaminants in the fuel injectors, allowing them to atomize the fuel in the correct way again.

How do you clean carbon buildup?

About a year into my ownership of a BMW 135i equipped with the N54 direct-injected engine, I discovered that my intake valves were horrendously caked with carbon buildup. I wanted to handle this project on my own and discovered that there are two main ways of removing carbon buildup from intake valves: soaking the valves in solvent and scrubbing them manually, or using a media blaster to spray off the carbon buildup using walnut media shells.

In the interest of saving money, I decided to try the former method, which required some intake valve cleaner (or carburetor cleaner), a set of hard plastic or soft metal picks, microfiber cloths, and compressed air either in canned form or from an air compressor.

With supplies in hand, I first turned the crank bolt manually to make sure that the intake valves on the cylinders that I was working on were fully closed. I then soaked the valves with solvent, scraped the carbon off of the valves, and used a microfiber to soak up as much carbon/solvent residue as possible. Any remaining dislodged residue can then be blown out of the intake ports with compressed air and wiped down again with a microfiber. This process can be repeated until all residue is gone. Media blasting the intake valves is another popular option that cuts the work time down significantly, as walnut shells do a very good job of stripping carbon off of the valves.