Why Your Car Stalls When It's Put In Gear: 6 Possible Causes

We may receive a commission on purchases made from links.

Most car owners have experienced the heart-sinking moment when you shift into gear and your car conks out. This can happen in your driveway, at a stop light, or while you're getting ready to pull out of a parking spot. The best case scenario is that it starts right up again, resulting in nothing worse than a brief worrisome moment before you're back on your way. With auto repairs often hard to estimate, knowing what might be wrong with your car gives you a leg up when you take it in for service.

When your car is in park or neutral, the load on the engine is minimal, and many issues will go unnoticed. Once you shift into gear and put demand on the engine, there are several potential reasons your car may stall. I have been working on cars for more than three decades, and in that time have encountered nearly every possible cause for an engine that stalls when put under load. With that experience as my guide, I offer a few possible causes of engine stalling, along with tips on some initial troubleshooting you can do before calling a tow truck.

You might have a problem with your fuel system

Whether your car uses gasoline or diesel fuel, an inadequate supply of fuel will cause your engine to stall out. This can be due to a clogged fuel filter, faulty fuel pump, or leaks in the fuel lines. Leaks under the hood are especially dangerous, because fuel that sprays onto a hot exhaust manifold or pipe can cause a dangerous fire. Check under the hood and along the frame rail for fuel leaks, and if you find one, have your car towed to a shop immediately.

If you notice no leaks, clean your fuel injectors before testing your fuel pump for adequate flow and pressure. If these tests reveal that not enough fuel is getting to your engine, try replacing the fuel filter first. Before loosening filter clamps, release the fuel pressure by removing the fuel pump fuse or relay and running the engine until it dies. If swapping in a new filter doesn't restore proper fuel delivery, it is possibly time to replace the fuel pump as well. If you're lucky, your car's fuel pump will be located along the frame rail, but most modern cars have the pump in the tank to help keep it cool. You may be able to get to it through an access hatch in the trunk or under the rear seat, but often you'll have to drop the tank to replace the pump.

Your engine also needs good spark to run properly

If pressure and volume tests reveal no issues with the fuel system, your stalling problem could be due to insufficient spark. This can be caused by worn or damaged plugs, a cracked distributor cap, bad plug wires, or a failing ignition coil. You can check for spark using an inexpensive test tool like this one from Harbor Freight. You should remove the spark plugs one by one and check them for fouling or damaged electrodes. You can also ground one of the plugs while a helper cranks the engine if you don't have a spark tester.

If you see a strong blue spark between the plug's electrodes, you should next check the coil's output with a multimeter. Also inspect the plug wires for any loose connections or obvious signs of wear. If the coil is providing enough juice and the plugs are clean, test each plug wire for resistance. You should also check for loose or damaged primary wiring running to the coil. It's a good idea to regularly replace your plugs, wires, and coil according to the manufacturer's specifications; this will keep your engine running well and help you eliminate possible issues while troubleshooting.

Low compression will also cause your car to stall

If you have enough fuel getting to your engine and sufficient spark to ignite that fuel, you may not have enough compression to keep the engine running when in gear. Low compression can be caused by a leaky cylinder head gasket, worn or damaged piston rings, damage to the cylinder walls or pistons, or slack in the timing belt or chain. You can find inexpensive compression testers at Harbor Freight or Amazon; these testers have fittings that screw into the spark plug threads and a gauge that measures the pressure generated inside each cylinder.

Most gas engines should have 100 to 150 pounds per square inch of compression; diesel engines usually generate at least three times that amount. All of your cylinders should measure within about 10% of each other, a larger variance can be a sign of a blown head gasket or damage to a particular cylinder.

Your valve system is also critical to proper engine operation

If your valve system isn't working properly, this can cause low compression or inadequate fuel delivery, even if your fuel pump and filter are functioning as they should. Valve system issues can range from improper adjustment to damaged or worn lifters and springs, any of which can make your engine stall when you shift into gear. If your valve system is damaged or needs adjustment, you may notice blue smoke in the exhaust, excessive oil consumption, or a ticking or rattling noise from under the valve covers.

Simply removing the valve covers and doing a visual inspection may reveal issues like damaged springs or loose rocker arms. This is also a good time to replace the valve cover gaskets; this is a common place for potentially damaging oil leaks. One easy way to make sure your valvetrain doesn't let you down is to change your oil and filter according to the manufacturer's recommendation. Check your owner's manual or call the dealership's service department to find out the recommended oil type and change interval for your vehicle.

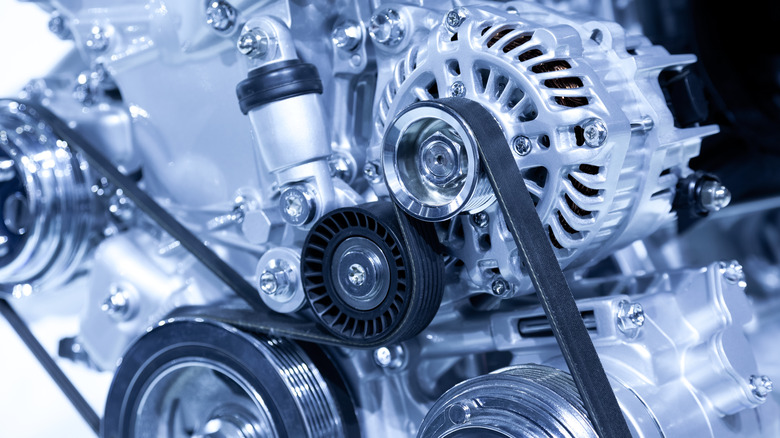

Failing engine accessories can put a load on your engine

If your fuel and ignition systems are working properly, and your engine has no compression leaks, it might be the belt-driven accessories mounted in front that are causing the engine to stall. Accessories include the alternator, power steering pump, and air conditioner compressor, all of which have bearings inside and pulleys that allow the engine's rotation to drive them via belts. If one or more of these accessories are damaged and putting excessive strain on the engine, it could cause stalling when you shift into gear. Usually this won't happen if everything else is ok with your engine, but it doesn't take much extra load in front to reveal other issues with an engine.

You can visually check the operation of the belt-driven accessories while the engine is idling, but keep your hands, tools, and long hair well clear from any moving belts and pulleys. Look for wobbling accessory pulleys and listen for bearing noises. To check for an issue with the accessories, remove the belt(s) and turn each accessory and the tensioner and idler pulleys by hand, feeling for binding or excessive resistance. The bearings inside the accessories will wear out over time, and this will happen faster if the belt(s) are too tight.

Electrical problems can also cause your engine to stall

Your engine also needs a steady supply of electricity to run properly, and there are many ways this supply can be interrupted. Loose or corroded battery terminals will reduce the current flowing through your car's electrical system, as will a loose ground wire. You can test your alternator and battery with a multimeter or have them tested at most chain auto parts stores; this will tell you if your system is recharging well enough to keep your engine running under load. Check the wiring going to the alternator for damage or loose connections, and make sure the belt is tensioned correctly.

You should be able to deflect the belt about a 1/2 inch at its longest point between pulleys. The problem could also be as simple as a loose relay or fuse, especially for your fuel system components. Check the power distribution center under the hood and/or fuse box inside the cabin. Make sure all the fuses and relays are seated completely; you should also check fuses with a dedicated fuse tester or your multimeter's continuity or resistance functions.