How 3D Printing Could Revolutionize The Way You Get Your Medication

Arts, automotive, and jewelry are some of the segments that have benefitted deeply from 3D printing, but it seems the healthcare industry is not far behind. The National Institute of Standards and Technology just released a paper talking about its trajectory and the need for regulations to ramp up 3D printing for making drugs more accessible, targeted, and in certain cases, flavorful, too.

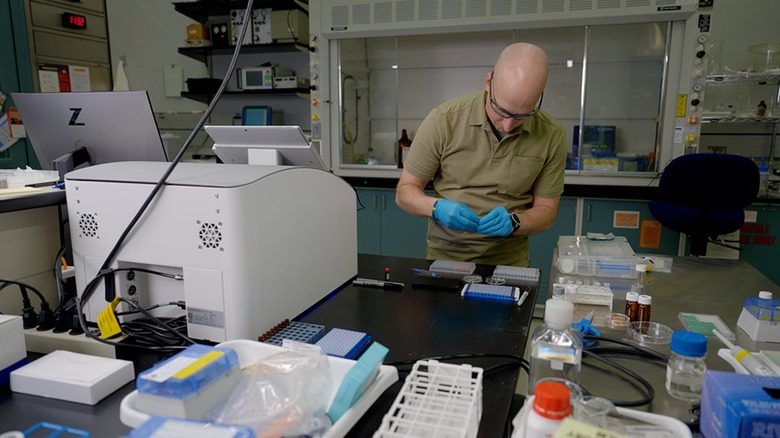

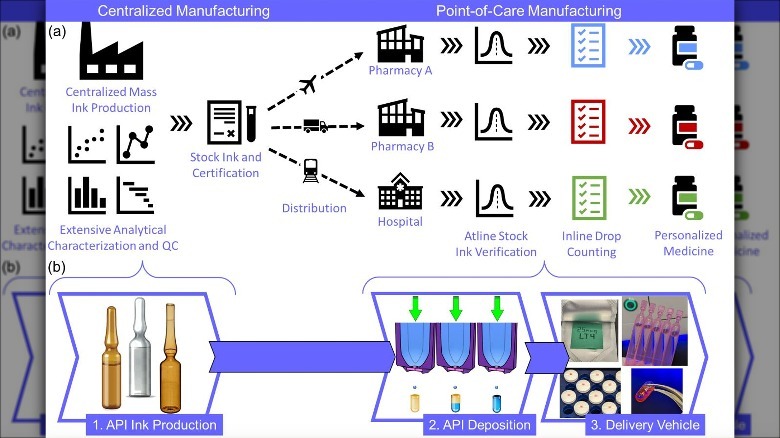

The team refers to the technique as distributed manufacturing, and hopes it will be of critical importance when there is a need for rapid manufacturing of drugs, like in an epidemic. Notably, these distributed manufacturing units can also work in tandem as a mass manufacturing unit at large pharmaceutical facilities. The team is advocating adherence to good manufacturing practice (GMP) standards at all costs. The goal is to deploy 3D printing units places like hospitals, pharmacies, or other kinds of registered healthcare facilities.

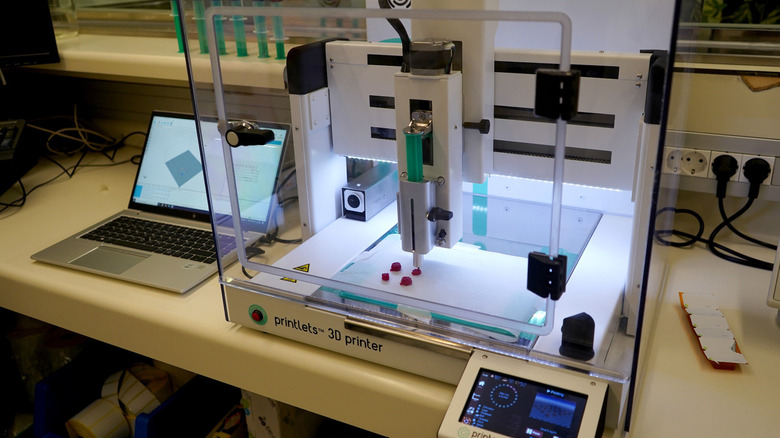

Compared to factories, the biggest advantage of these 3D printers is that they will "produce small batches down to single dose allotments," opening the doors for "personalized precision dosages/therapies for individuals." That means we can not only expect medicines to come in a perfect dosage but also in a chosen shape and preferred flavor, too. Notably, the manufacturing standards applied to these on-site machines would differ from those expected from large-scale pharmaceutical manufacturing units, without compromising the safety and quality standards for the end product.

A personalized and diverse approach

One of the biggest advantages of 3D-printed drugs is that it solves the dosage size issue. For example, there are many drugs that don't come in multiple sizes. For example, a young patient might require only a 5mg dosage of a medicine, but the required pill is only manufactured in double that dose by a pharmaceutical company. With 3D printing, medicines can not only be printed and delivered based on the size of the dosage required, but also tailored to the specific, potenitally changing, needs of a patient.

Another crucial benefit is that 3D printing also offers flexibility in terms of the medication's format. For patients with difficulty swallowing a capsule or pill, they have a choice to access it in a liquid form. Alternatively, vapor deposition allows the creation of medicines in the form of films that dissolve in the mouth. Moreover, the technique can also end the chore of having to pop multiple pills at once. Thanks to the "polypills" approach, multiple drugs can be combined into a single package.

As far as children are concerned, the psychology of taking medicines is another tough task. With 3D printing, medicines can be produced in shapes that can appeal to children, such as stars or animals. Moreover, the bitter taste can also be taken care of, by customizing the chemical constituents to taste like chocolate or fruits of their choice. A paper published in the Molecular Pharmaceutics journal describes a technique that involves "microextrusion for the processing of powdered blends" to make ibuprofen (an easily-accessible over-the-counter drug for treating pain, fever, and inflammatory diseases) in a chewable form that comes in orange and strawberry flavors.

What's next?

The techniques discussed in the research paper are inkjet and drop-on-demand printing to achieve precision deposition of the chemicals that go into making medicines in multiple forms such as films, tablets, and capsules. According to NIST, 3D printing could also help handle pandemics more efficiently by speeding up the pace of vaccine delivery to the public.

The agency has kept an eye on all the key developments in the field of 3D-printed pharmaceuticals, and plays a crucial role in setting up quality standards. It notes that supplying the right raw material to the site is of utmost importance, as factors like temperature and state change decide if a material is still effective or if it has degraded.

Equally important is the quality assessment of the 3D printers. As part of its internal testing, the NIST learned that LEDs and photodiodes are reliable methods of detecting issues such as blockage of the printer nozzle, contamination, or scenarios where the kit has run out of medical-grade ink. However, one crucial piece of the puzzle remains unsolved, and that is verifying if the correct dosage has been printed.

The research paper points out that folks managing these local drug-making sites would need to adhere to certain safety protocols. These rules would make sure that only drugs that meet official quality standards are made at these sites to meet patient needs.