Is Detroit's DD15 Engine The Same As Its Series 60? What You Need To Know

Detroit Diesel has been in the engine-building game for over 85 years, and in that time they have established themselves as one of the most reputable diesel engine manufacturers in the country. Initially a subsidiary of General Motors, Detroit Diesel was tasked with building compact diesel motors for use in military vehicles and construction equipment, with their Series 71 two-stroke engine playing an important role in powering America's WWII war effort. Detroit Diesel initially built their brand on two-stroke diesel engines — which complete an entire power cycle in two piston strokes instead of four — sacrificing efficiency for power. In the 1950s, Detroit Diesel entered the on-highway market, offering their popular Series 53 two-stroke diesel in commercial trucks.

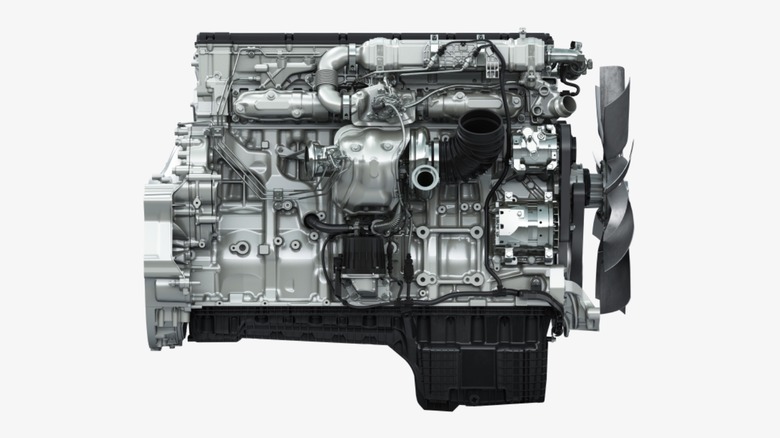

After Detroit Diesel merged with GM's Allison Division in 1970 to become the Detroit Allison Division, things began to change for the company that was known for building two-stroke diesels. Their competition, primarily Cummins, was doing well with more efficient four-stroke diesel engines which tended to be more fuel efficient and produce fewer emissions — two pros in an increasingly more environmentally conscious world. As a result, Detroit Allison built their first four-stroke engine in 1989, known as the Series 60. In the years following its release, the Series 60 became the best-selling four-stroke commercial diesel in the United States.

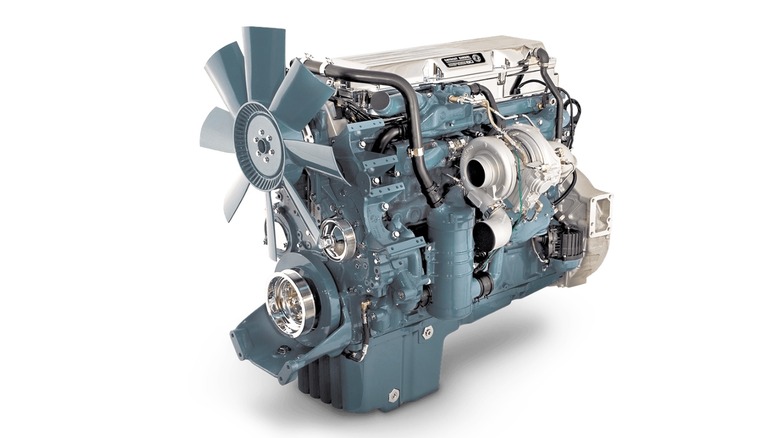

In the following decades, the Detroit Allison company went through some significant changes, including two changes of ownership, that kept Detroit's forward momentum rolling. In 2005, they spent $300 million to refresh their plant and tooling. They also invested $1.5 billion into a new four-stroke engine line called the DD engine series, which included the DD15. The new series was a completely new design that was far more technically advanced than the Series 60, making it more powerful and emissions-compliant.

The DD15 featured a completely new fuel system

One of the biggest differences between the Series 60 and the DD15 is their methods of fuel delivery. When the Series 60 was introduced in 1987, electronic fuel injection wasn't as sophisticated as it was in the mid-2000s. As a result, the Series 60 utilized a more mechanically driven electronic unit injector system. The Series 60's EUI system relied on a camshaft-driven mechanical pump to actuate a spring-loaded fuel injector, which pressurized fuel before it was injected into the combustion chamber. Timing and fuel metering were controlled by the ECU, serving as the "electronic" aspect of EUI. While EUI reduced fuel consumption, lowered emissions, and increased power compared to earlier systems, it was more likely to fail since it relied on so many mechanical actions to perform correctly.

In contrast to the Series 60's EUI fuel system, the DD15 uses a more advanced but less intricate Amplified Common Rail System to deliver fuel to the combustion chamber. Instead of using a camshaft's rotation to pressurize the injectors, the DD15's fuel system simply used a high-pressure fuel pump. The main benefit of the DD15's fuel system was the fact that injector fuel pressure remained constant at 30,000 PSI regardless of engine speed, making fuel injection more consistent and more controllable across the entire rev range. In practical terms, that means more low-end torque and more power than the Series 60's system.

It also used a new turbo compounding system

Turbo compounding is a concept that has existed since the 1950s but was used primarily on aircraft engines before Detroit Diesel reinvented it for diesel engines on the road. In essence, turbo compounding is the process of harnessing otherwise wasted exhaust gas heat to produce more power. Detroit Diesel did it in a very creative way by using a single Holset turbocharger and a secondary turbine.

The secondary turbine recovers exhaust energy from the primary turbo and translates it directly to the engine's flywheel. The DD15's use of turbo compounding added up to 50 horsepower and 100 lb-ft of torque compared to the Series 60 which lacked turbo compounding while also making it five percent more fuel efficient. Detroit Diesel eventually swapped out the initial DD15's turbo compounding system with a single asymmetric ball-bearing turbo in 2013 which produced more power and torque lower in the rev range.

The DD15 went further with emissions reduction

In 2007, the EPA announced that heavy-duty on-highway diesel engines would have to comply with much stricter emissions regulations than in the years prior. The new regulations called for a 55 percent reduction in NOx and a 90 percent reduction in particulate matter emissions. As a result of the stricter emissions requirements, many on-highway truck and diesel engine manufacturers, including Detroit Diesel, were forced to make changes to their existing trucks and engines to meet the emissions thresholds. Detroit was ahead of the game, as they had already equipped the Series 60 with exhaust gas recirculation technology during a previous emissions regulation change in 2002. The Series 60's EGR system rerouted some of the engine's exhaust gas back into the intake manifold, reducing cylinder temperatures and NOx emissions as a result. For the 2007 emissions regulations, the Series 60 also received a diesel particulate filter which was used to trap excess soot and other exhaust debris and burn them off at high temperatures.

In contrast to the Series 60, which was adapted to accommodate the changing emissions requirements, the DD15 was designed around the 2007 regulations. The Amplified Common Rail fuel System and turbo compounding systems went a long way to make the DD15 better suited for the stricter regulations, and other changes decreased its emissions output even more. Like the Series 60, the DD15 uses both exhaust gas recirculation and a diesel particulate filter. The DD15's revamped EGR system utilizes an integrated coolant manifold, reducing NOx emissions while also improving fuel economy. The DD15's DPF was also upgraded with a new fuel injection system, allowing it to burn off contaminants more effectively.