iPhone Repairs May Soon Be A Lot Easier (And Cheaper) For Everyone

Over the past few years, the right-to-repair movement has gained a considerable amount of steam, but it was the intervention of government agencies — especially in regions like the European Union — that manufacturers have finally started to make meaningful changes. For example, the recent adoption of a do-it-yourself (DIY) approach for selling genuine parts, supplying guides, and letting an average person perform repairs was a step in the right direction coming from brands like Apple, Samsung, and Microsoft, among others. But there are still a handful of hurdles, and the most notorious among them is the adhesive.

According to The Information, the adhesive troubles could finally be a thing of the past, at least when it comes to accessing and replacing the battery fitted inside an iPhone. The report mentions Apple exploring a technology called "electrically induced adhesive debonding" for batteries fitted inside the iPhone chassis. The novel part about this approach is that the lithium pack will be lodged inside a metal shell instead of covering it with foil.

Applying electricity to this metal would act as an electrochemical catalyst that will nullify the adhesive bonds and let users take out the battery with ease. The core objective here is that there won't be a need for a heat blast to melt the adhesive around the battery and the rest of the circuit board. This unique approach not only means repair costs will come down, but it's also great news for DIY enthusiasts.

Why the shift?

One may ask why exactly is Apple making these changes. Well, it has to do with regulations in the EU bloc that were introduced last year and a proposal for battery recycling as well as battery designs that are easily removable and replaceable. On a similar note, the Indian government's Right to Repair framework also pushes reforms that aim to make it easier for an average person to access and replace batteries without spending money on buying an altogether new product while worsening the e-waste crisis.

The Atlantic Council has a fantastic overview of the situation from a consumer viewpoint of the push for greener solutions to handle batteries inside consumer electronics items like smartphones. This is where the electrically induced adhesive debonding comes into the picture. It's not a novel idea coming from Apple's design labs.

In fact, the electronics and aviation industries have been eyeing a wider adoption of this tech for a while now, primarily because it's not only easier, but also reduces the risk of thermal and mechanical damage to other components around the battery that are held together by the adhesive. Right now, repair experts have to rely on heat to take apart the adhesive holding the battery in place inside an iPhone's chassis. The method works, but it makes the whole process of repair and replacement notoriously messy and time-consuming. The experts at iFixit have been complaining about it for years, and yes, they lambasted Apple for it, as well.

How does the tech work?

A few years ago, when batteries were user-removable and had a hard-case design, they were encased in a solid single-unit container that could be removed with bare hands. When electrically induced adhesive debonding comes into the picture, the battery once again needs to be kept inside a boxy structure, and this time, it's metallic for applying the necessary voltage to change the adhesive structure.

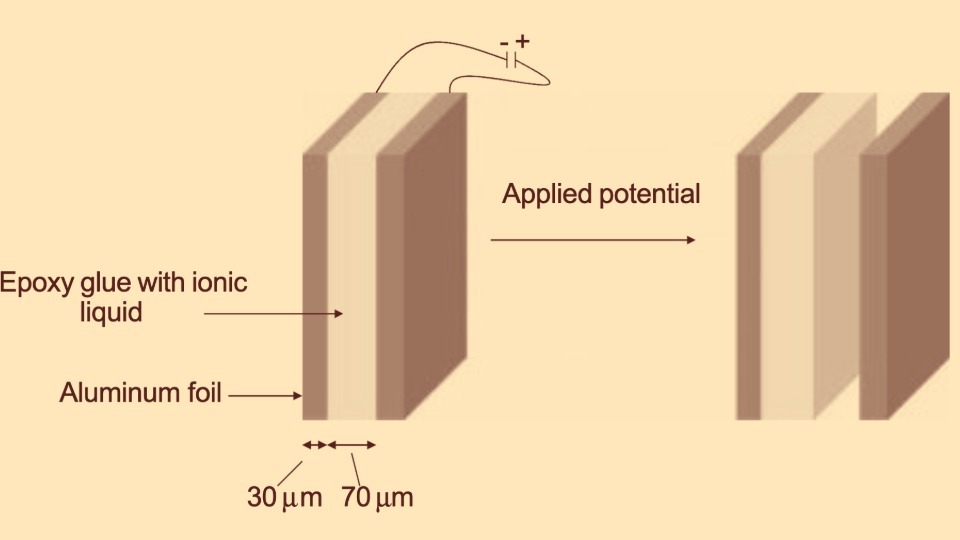

According to a research paper published in the International Journal of Adhesion and Adhesives, an epoxy resin needs to be mixed with metallic ions (to create ionic conductivity) and placed between two metallic plates that act as electrodes. When voltage is applied, the debonding process starts and the adhesive detaches itself from one of the electrodes, as shown in the figure below. The paper refers to this method as "design for disassembly," which is exactly what the EU is chasing for batteries fitted inside gadgets, such as iPhones.

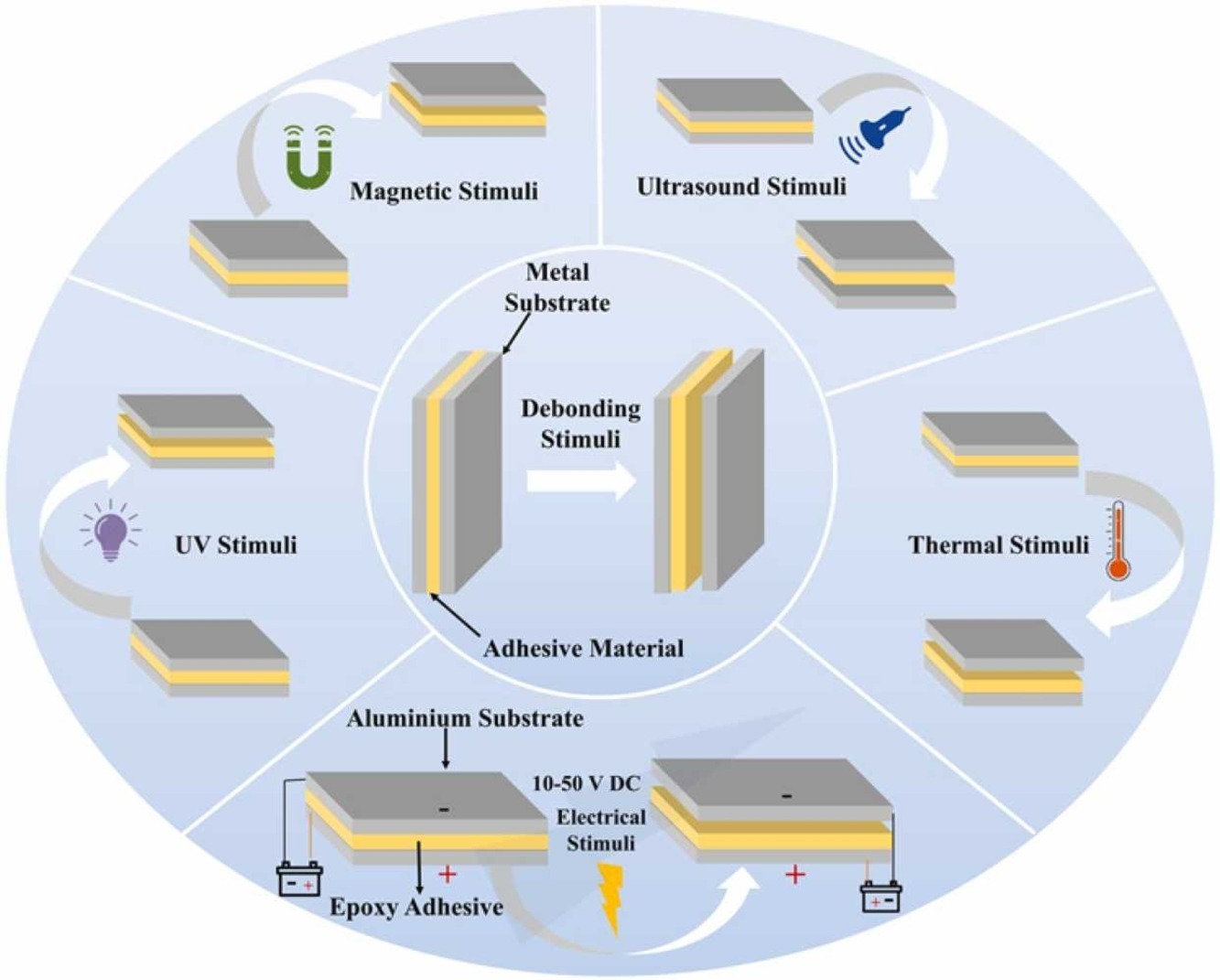

Now, debonding can happen in multiple ways, such as using a magnetic field, UV rays, and even ultrasound, but electrical debonding is particularly promising because it can even be accomplished remotely, as described in this research published in the Materials Today Communications journal. In this case, the metallic additives that allow the adhesive debonding could be solvated salts or ionic liquids.

According to this paper published in the Advanced Materials Interfaces journal, these "adhesives are currently of high interest in the aerospace and electronics industry" because they reduce the risk of thermal, mechanical, or chemical damage to electronics when there is a need to repair or replace certain components.

How this could change batteries forever

The adhesives used inside gadgets at the moment have their own set of advantages, as they replace methods like soldering and offer a certain degree of mechanical as well as chemical protection, such as liquid exposure for waterproofing. However, chasing all those benefits has meant smartphone makers have adopted the risk-prone foil design for batteries with generous use of pressure-sensitive adhesives (PSI) to go with it.

Using adhesives that can be debonded with the application of a small current and modifying the design of batteries accordingly so that they can be removed easily and with lower risks is the ideal way forward. One of the best explanations of how electrically induced adhesive debonding in the context of making recyclable batteries is offered in a paper published in the Next Energy journal.

Titled "Designing lithium-ion batteries for recycle: the role of adhesives," it mentions tweaks such as reducing the number of cells, getting rid of heat-dependent adhesives, cells that can be opened with ease, and batteries that can be debonded using pressure or electricity.

"As well as reducing the energy consumption of the disassembly processes, it also reduces the number of steps required, which would be beneficial to the overall economics and GWP [global warming potential]," says the paper. At the end of the day, that's what an average iPhone buyer would want, which is being able to get an aging battery removed with ease and replaced with a fresh one, instead of having to buy a new phone.