What Are Ryobi's Brushless Tools And Are They Any Good?

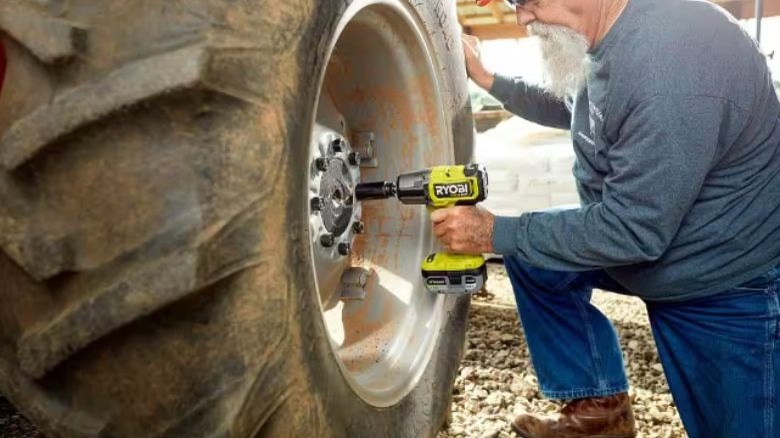

Shopping for tools can either be a straightforward process or one that requires a little research. Buying a new Philips screwdriver takes seconds. Choosing a new power tool, however, can be a little more complicated. Even if you know the brand, like if you're faithful to Ryobi, some things may throw you for a loop. For example, what exactly are you buying when you pick up Ryobi's brushless hammer drill or the brushless impact wrench?

You likely know what the tools themselves are, but what does a "brushless motor" mean? It's not listed with every Ryobi tool, such as the PCL265K12 impact wrench or the P519 reciprocating saw, so it must mean something. It actually means a lot, and it has everything to do with the tool's motor. Added to Ryobi's 18V ONE+ line in 2020, brushless technology results in a far more efficient and longer-lasting motor by relying on a circuit board to simplify a surprisingly complex process.

To best understand how a brushless tool works and why they've taken over the market, it's also best to know what a brushed motor was and why it's considered antiquated technology. Regardless of which system your power tool is using, it all starts with magnets that are ultimately responsible for the drill bit spinning or the saw blade reciprocating.

Brushless brings new technology to an old application

Regardless of the tool you're using, they all have the same end goal. You need the engine inside to create a specific motion to get the job done. Both brushless and brushed motors do that, but brushless motors do it without two carbon brushes flanking what's known as the commutator.

In a brushed motor, the armature, or the rotor that drives the drill bit, is attached to the commutator, which is touched by spring-set, stationary brushes. When you pull the trigger on the tool, it sends a current that courses through the brushes and commutator to magnetize the armature's wire coils. A pair of magnetics with differing polarities known as the stator push and pull the armature, rotating the shaft. While the process is occurring, the commutator is working with the brushes to create a perpetual motion of the armature being pushed and pulled to make the tool work.

A brushless motor is made up of a rotor, stator, and an electronic controller. When you pull the trigger, the controller does all the work. First, it determines which polarity the coils need to work with or against the permanent magnets on the rotor. It then determines how much of a charge is needed to start the process of turning the rotor. While running, the controller increases or decreases the charge as it deems necessary to keep the rotor spinning and the tool working.

Why is a brushless motor better than a brushed motor?

One of the biggest advantages that a brushless motor has is fewer components. There are no brushes to wear down and no commutator to break. The three main components of the brushless model allow for a more compact assembly, but that doesn't mean brushless tools are necessarily lighter than brushed. Ryobi's ONE+ HP 18V Brushless Impact Wrench is still just under 2 lbs heavier than the brushed model. However, the brushless option can achieve a maximum torque of 14,040 lbs compared to 4,500 lbs.

Along with a simplified construction, brushless motors are more efficient than brushed motors. With a brushed motor, the tool runs on the same current no matter the task. Whether you're drilling into concrete or screwing into drywall, the battery expels the same charge. The controller of a brushless tool is better at power consumption and efficiency. It will only use what's needed for individual tasks, meaning you'll use far less energy on lighter tasks.

The only real cons with brushless motors are their price and repairs. Generally, brushless tools will cost more, as seen with the impact wrenches. Since they run on a circuit board, they're more difficult to repair than the nuts and bolts construction of a brushed motor. When using a brushless motor, you also should be mindful of the conditions you're working under. Water and other debris are going to affect the circuit board more than it would the brushed motor setup.