Everything You Need To Know About The Bentley W12 Engine

Pioneering new engine technologies has always been an integral part of Bentley's DNA. The second car ever made by the British marque, introduced a year after the end of World War I, featured a monoblock four-cylinder engine with four valves per cylinder, twin spark plugs, and twin magnetos. It also featured aluminum pistons, an innovation that the company's founder — W.O. Bentley — spearheaded before the world descended into chaos. Needless to say, the 3-liter four-cylinder found in the 1919 Bentley EX2 set a benchmark for performance roadcar engines from that point forward.

By 2003, Bentley was a much different company. In fact, Bentley wasn't truly Bentley at all by that point. That change occurred in 1998, when the Volkswagen Group purchased a 100% stake in Bentley from Vickers PLC and BMW for $745 million. The man behind the purchase was Ferdinand Porsche's grandson and then VW CEO Ferdinand Piëch, who has not only been credited as car executive of the century but also as a visionary automotive engineer.

The VW buyout led to an exchange of intellectual property and a new vision for Bentley. With a man like Piëch steering the ship, it's no surprise that radical and innovative solutions were taken to revive Bentley, and part of that plan was introducing the VW Group's unique W12 engine layout to a number of flagship models. Despite Bentley no longer being Bentley, Volkswagen stayed true to Bentley's powertrain pioneering roots and the W12 was at the center of it all.

The W12 is essentially two VW VR6 engines mashed together

While Bentley might have had the longest-running series of W12 engines, it wasn't the first to introduce them. The first W12 engine was introduced in 1917 by D. Napier and Son to serve WWI-era planes that could benefit from a compact engine design and stronger internal components. It used three banks of four cylinders including a central upright bank and two canted banks to each side of it, forming somewhat of a W shape. The design allowed for a 12-cylinder design that didn't require the additional length needed to accommodate a traditional V12 engine.

While the Bentley W12 took a similar philosophical approach, its design was quite different. Bentley's W12 wasn't an original design, it was a borrowed design from Volkswagen that had already been implemented in the Audi A8 and Phaeton. However, the W12's design can be traced even earlier to the famed Volkswagen VR6 engine, a huge innovation in engine technology.

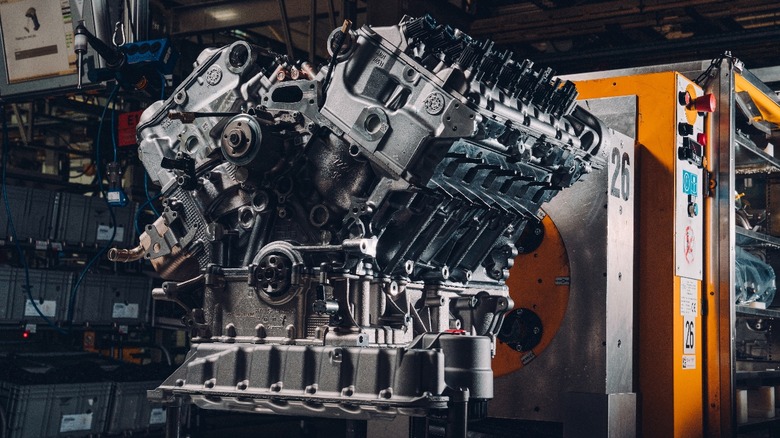

Like the Volkswagen VR6, the W12 was a combination of inline and "V" engine configurations. It features two banks of six offset cylinders that share a common crank. Each of those banks is essentially a V6 engine, only at a minuscule 15-degree bank angle allowing them to share a single cylinder head. VW's design means that their W12 is as longitudinal stout as D. Napier and Son's while not being as vertically intrusive. Bentley versions received twin turbos, and eventually twin-scroll turbos, from their release in 2003.

The W12 steadily evolved through the years

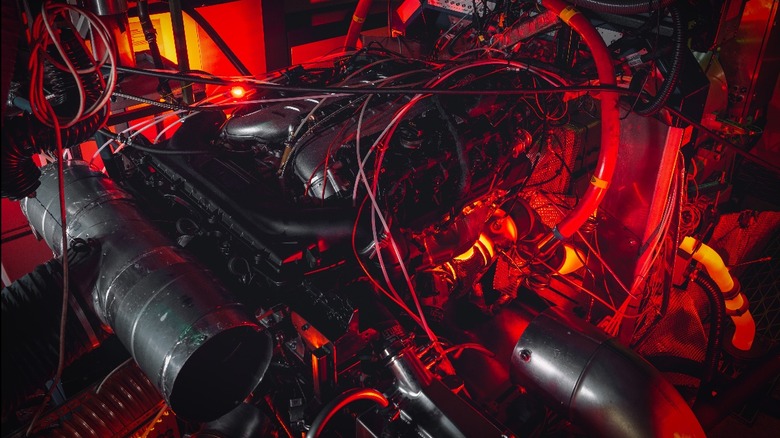

The Bentley W12 has changed and adapted to the times. When the engine first appeared on the scene, it was advanced in terms of its overall design, but it was still limited by its fuel injection system, cooling system, and turbo technology. This is evident through its modest 552 horsepower output, considering its cylinder count and use of twin turbos.

The W12's upgrades were slowly introduced to the engine over the course of years to make it a better-performing and more efficient engine. By 2012, the W12 was up to 567 horsepower and 516 lb-ft of torque thanks to those upgrades. Among them were a re-tuned engine control unit, an upgraded oil cooler, redesigned intercoolers, improved Warner turbochargers, and direct injection. Those changes also bumped the upgraded W12's fuel economy to a slightly less miserable 15 combined MPG compared to the initial engine's pitiful 12.

While the Bentley W12 did see some significant upgrades in the first 12 years of its production, its 2015 upgrade essentially turned it into a different engine. That year, Bentley completely redesigned the W12 from the ground up for the release of the Bentayga. Think of the W12's initial upgrades as a trial run for the real thing, as the redesigned engine's upgrades mirrored those of earlier years but to an even more extreme degree. It was given a combined direct and port injection system for increased fuel flow and reduced carbon buildup and was also upgraded with new twin-scroll turbochargers. Most significantly, the W12 was given cylinder deactivation technology which allows it to shut down half of its cylinders when not under load.

Production of the W12 came to a close at the end of April 2024

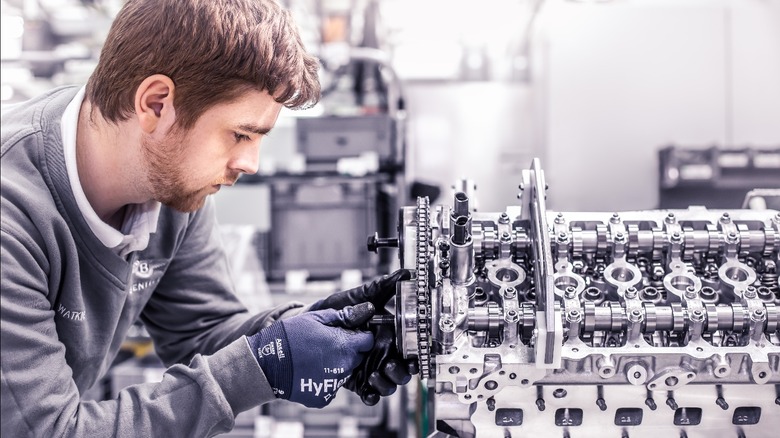

By April of 2024, Bentley's factory in Crewe, England had produced over 105,000 W12 engines since beginning production in 2003. The Crewe factory itself has come to define Bentley's history over the years, having produced the majority of Bentley models since the Bentley Mark VI in 1946. It was also the location where all of Bentley's W12 were hand-built by a team of craftsmen over a total period of 6.5 hours. Over 20 years of dedication to the W12 platform ended in 2024, when Bentley decided to pull the plug on the W12 engine for good.

In its place, Bentley intends to focus on more modern, more potent, and more efficient motors that will carry the brand further into the 21st Century. In 2019, Bentley made a statement that it was committed to switching to an entirely electric lineup by 2030, a claim that it looks like the brand will adhere to. For the time being, however, it only has one foot out the door, with a range of hybrid V6 and V8 engines still on offer.

Despite being a formidable power plant for Bentley for two decades, the automotive climate has fossilized the unique engine and constrained it to the increasingly disappearing internal combustion era. It seems like that's a common theme no matter where you look, with only 10 brands still manufacturing V12 engines in 2024.