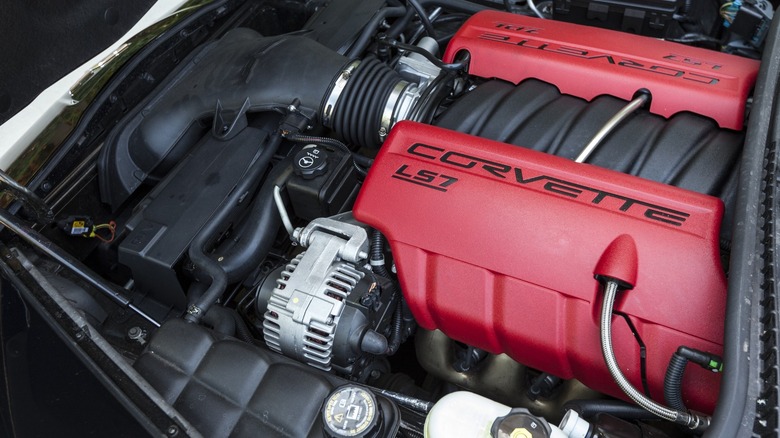

This Design Feature Is Why LS Engines Can Handle So Much Horsepower

General Motors' LS engine lineup has been fascinating gearheads and auto lovers since it was originally released in 1997. The engine has powered some of GM's most popular cars, trucks, and SUVs, including models like the Chevrolet Camaro, GMC Sierra, Chevrolet Tahoe, and the always evolving Chevrolet Silverado. The LS engine line is notorious for its absurd horsepower and torque outputs, and LS engine swaps have become one of the most popular ways to introduce massive amounts of power to various vehicles.

But what is it exactly that makes LS engines so great? The answer is multifaceted and ultimately lies in the motor's overall construction. However, one of the most critical factors contributing to LS engines' massive horsepower capacity is GM's use of six-bolt main bearing caps. Main bearing caps are internal engine components and are integral to the engine's performance. They maintain the connection between the piston connecting rods and the crankshaft, allowing the pistons to move up and down as the crankshaft turns. While many main bearing caps have two or four bolts holding them in place, LS engines utilize six bolts, resulting in a significantly stronger connection and the potential for substantial power outputs.

That's a heavily simplified breakdown of a pretty complex subject. So, to explain things a little more clearly and to help you understand why LS engines can handle so much horsepower, let's dive in and explore these iconic motors in greater detail.

LS engines are built for peak power

LS engines are designed to handle incredible amounts of horsepower and torque. That capacity for extreme power starts with a solid base. With the exception of a few truck-specific motors, most LS engines have aluminum blocks. That translates to an incredibly strong and lightweight base, resulting in a robust engine case that's strong enough to stand up to extreme power without being overly heavy and weighing down the vehicle.

Another feature that makes LS engines both powerful and versatile is their pushrod construction. There are two common types of modern internal combustion engines: pushrod and overhead cam (OHC). Pushrod engines have one camshaft located below or between the cylinder heads in the engine block. The timing chain turns the camshaft, which in turn moves a series of rods that open and close the cylinders' exhaust and intake valves.

OHC engines have camshafts located in the cylinder head above the pistons. The timing chain or belt still turns the cams, but the primary difference is the location of the camshaft(s). This may seem insignificant, but pushrod engines are substantially smaller than OHC motors without sacrificing power. This fact alone contributes to LS engines' potential for power and their desirability as swap motors.

LS engines are also built with a greater amount of space between the camshaft and crankshaft than many other motors. This allows the engine to support a longer piston stroke, resulting in an efficient increase of torque and horsepower.

The main bearing caps are the stars of the show

We mentioned that one of the most critical factors that allows the LS engine lineup to handle such monstrous horsepower outputs are its six-bolt main bearing caps. This design contributes to power capacity by increasing the strength of the connection between the piston rods and the crankshaft. That system works due to the four vertical bolts and two horizontal bolts that combine to form an incredibly solid connection, allowing tuners to squeeze every drop of power from the engine without the risk of damage.

In other engines, main bearing caps have two or four bolts. However, over time, those connections can weaken, especially if drivers modify their engines in an attempt to generate more power. When the connection between the pistons' connecting rods and the crankshaft fails, the pistons may begin moving erratically, and more severe engine damage will likely follow. Ultimately, a faulty main bearing cap can cause complete engine failure.

The LS engine lineup's use of six-bolt main bearing caps has allowed it to achieve legendary status in the world of gearheads and car lovers. Each of the engine's numerous generations is renowned for robust power and reliability, thanks in no small part to GM's use of incredibly stout six-bolt main bearing caps.