GM LT4 Vs. LT5 Engine: What's The Difference?

The fifth generation of GM small-block was released in 2014 to cautiously optimistic enthusiasts around the world. The previous third and fourth-generation GM small-block V8s were not only special, but they became the blueprint for everything that an American pushrod V8 should be for over two decades between 1997 and 2020. Luckily, the LT engine series lived up to its predecessors and introduced new innovations that the LS series lacked.

While the naturally aspirated engines in the series, especially the LT1 and LT2 V8s, got the job done in lower-tier models of the Corvette and Camaro, the supercharged entries in the fifth-gen small block family are the ones that have truly pushed the platform to its limit. To this point, there are two blown entries of the GM LT small-block, including the LT4 and LT5.

Being a part of the same engine family, the LT4 and LT5 are fraternal twins. In fact, the supercharged 6.2L LT4 — released in 2015 — served as a springboard for the LT5's success. Like all the other engines in the LT engine series, both the LT4 and LT5 are 90-degree V8 engines with cast aluminum blocks and cylinder heads. Both engines also feature the same cast aluminum pistons and forged powdered metal connecting rods, along with most other key internal components. While the LT4 and LT5 are similar on paper, they are differentiated by a few key components.

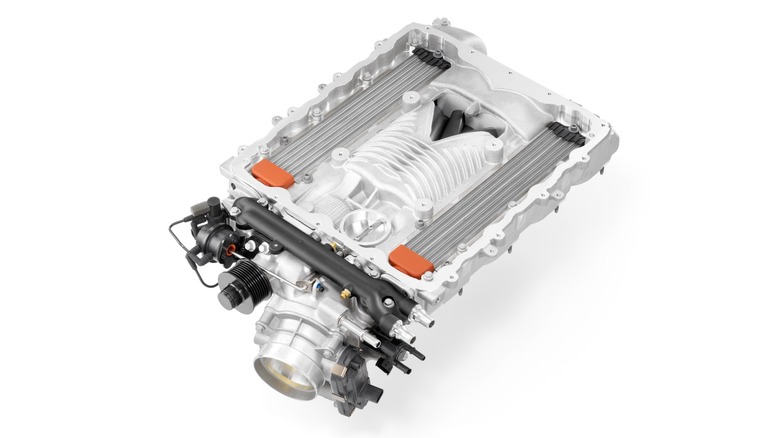

The LT5's supercharger means business

The LT4 and LT5 have more similarities than differences, but the differences that they do have are pretty notable. There's over 150 horsepower separating the output of the LT4 and LT5, with the majority of the LT5's additional horsepower coming from its larger displacement supercharger. The LT5's 755 horsepower output makes it the most powerful production engine that GM has ever put under the hood of a car.

Both the LT4 and LT5 make use of Eaton TVS roots-style superchargers, which are good for instant torque and power right off the line. The earlier LT4's supercharger was really nothing to write home about. At 1.7 liters, it was significantly smaller than the 2.3L supercharger found on the previous generation LS9 V8. It also needs to spin faster to produce a similar amount of boost — about 9 psi in factory form — than larger displacement blowers, producing more heat as a result.

In comparison, the LT5 uses a similar Eaton R2650 TVR supercharger, but with a lot more displacement. The LT5's 2.65-liter blower is 64 percent larger than the LT4's, which is a massive difference in the world of superchargers. The additional size means that it is able to produce significantly more boost — around a 13.9 psi peak in factory form — and at over 5,000 rpm slower than the LT4's supercharger, making more power and producing less heat.

The LT4's fuel system was beefed up for the LT5

Outside of the supercharger differences between the two engines, the LT5 also received a revised fuel system compared to the earlier LT4. One of the most significant differences between the LT engine series and earlier LS engines is the former's use of a direct injection fuel system. Compared to port injection, which the LS engines employed, direct injection is superior in nearly every way, with the most significant benefits being improved fuel economy, better power production, and increased engine safety/knock resistance.

While direct injection's laundry list of benefits outweighs its negatives, DI has its own set of faults. Since direct injection systems deliver fuel directly into the combustion chamber, they don't provide the same valve-cleaning effects that port injection systems offer, as fuel never flows over the intake valves. The 6.2L LT4 used a direct injection fuel system only. As a result, carbon builds up on the backside of the LT4's intake valves over time, which can lead to decreased performance and other engine issues.

To address that issue and create a more optimized overall fueling package for the LT5, GM introduced a dual-fuel injection system that uses both port injection and direct injection. The LT5's dual PI/DI system takes advantage of the strong suits of both fuel system types, with all the advantages of a direct injection system and the innate valve cleaning attributes of a port injection system. The additional PI system also reduces the amount of strain put on the direct injection system and makes the fuel system more upgradable in the future for modifications down the road.

The LT4 and LT5 are distinguished by a number of smaller changes

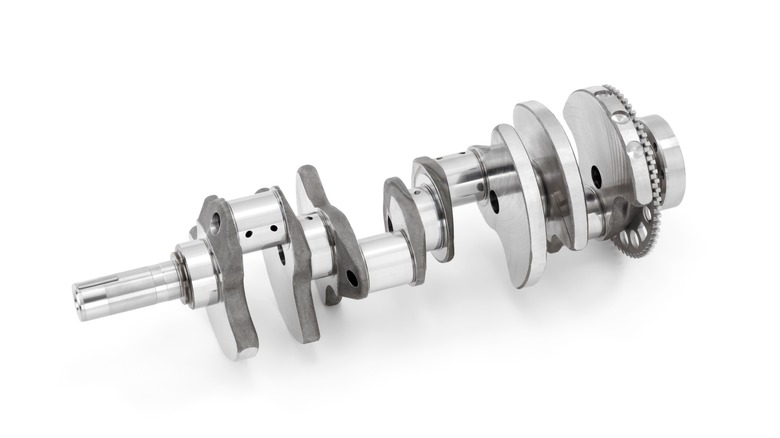

Most of the differences between the LT4 and LT5 have been accounted for at this point, but there are some important additional bits and bobs that GM also changed to account for the LT5's significantly increased power and torque output over the earlier engine. The most significant of those smaller changes include a revised bypass valve design and a stronger crankshaft.

On supercharged engines, including the LT4 and LT5, bypass valves play a critical role in moderating how much air reaches the intake side of the engine. The bypass valves of the LT4 and LT5 work in different ways. The LT4's bypass valve is a more traditional vacuum-controlled design, which routes air around the supercharger and closes when a certain manifold pressure is reached. The LT5's is electronically controlled. The LT5's bypass valve is actually a throttle body that was borrowed from the L5P Duramax turbo diesel engine. The LT5's electronically controlled valve allows for more precise airflow leading to better throttle response and torque lower in the rev range.

Crankshafts are often considered the backbone of an engine, as all the internal reciprocating elements are attached to it. For that reason, it is critical for a crankshaft to be strong, especially when it comes to a 755 horsepower monster like the LT5. Due to the LT5's additional power over the LT4, its crankshaft was also revised to handle the additional forces. The main difference between the crankshafts is the material that they are constructed from, with the LT5's being forged from a stronger steel alloy. The LT5's larger supercharger also required a beefed-up 11-rib belt, requiring an additional crankshaft groove.