V6 Vs. VR6 Engines: What's The Difference?

The world of engine development is a complicated one. The number of variables that need to be considered when shoving a power plant into any given chassis is so high that it'd make even a seasoned engineer's head spin. There's truly an art to developing an engine that checks all of the boxes, from meeting emissions requirements, to developing an ample amount of power, to ensuring that the bloody thing even fits in the car that it's supposed to.

Six-cylinder engines are a very popular choice among car manufacturers when it comes to choosing an engine layout for a midsize or compact car, for a couple of reasons. They occupy a good middle ground between size and performance. Traditionally, manufacturers have had the choice between inline-six and V6 configurations when going the six-cylinder route — with each having its own set of advantages and disadvantages.

Inline-six engines are naturally balanced, meaning that the reciprocating forces within the engine equal each other out, leading to much smoother power delivery. They're also cheaper to build, typically easier to work on, and use fewer parts. However, that comes at the cost of their extreme length, making packaging impossible in a small car. V6 engines solve that issue by being shorter and wider due to having two banks of cylinders. However, they are less balanced, more complicated, and more expensive to produce.

That's why Volkswagen took a stab at building an engine with the benefits of both straight-six and V6 engine layouts without any of the issues. The Volkswagen VR6 engine was the successful result of that experiment.

How are V6 and VR6 engines similar?

Starting with the obvious, both V6 and VR6 engine layouts feature six cylinders. The "V" in VR6 means the same thing that the "V" in V6 does; representing that both engines have two angularly opposed banks of cylinders. Since there are six cylinders in total, with both V6 and VR6 configurations, each has two banks of three cylinders.

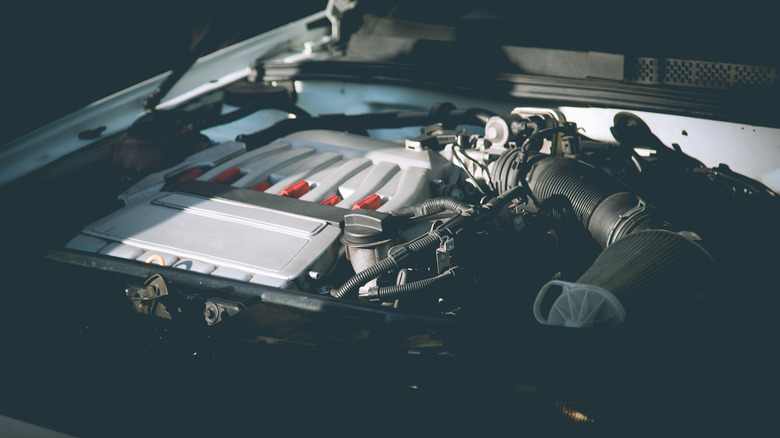

The biggest advantage that V6 engines have going for them is their small form factor. V6 configurations make for a short and wide form factor due to their cylinder banks being slanted away from each other, instead of having all six cylinders in line. That means that they can generally fit in a small car's engine bay in both a longitudinal or transverse layout. That was critical for Volkswagen when they were designing the VR6, as most of the cars that the engine was designed to be used in were not only tiny, but also came with different drivetrain arrangements requiring different engine orientations. +

So, in order for the VR6 to keep a V6's shape, its two cylinder banks were given either a 10.6-degree or 15-degree bank angle depending on the variant.

Why the VR6 engine is different from a traditional V6

While the VR6 might have a "V" in its name and two angled cylinder banks, it has much more in common with an inline-six configuration than a V6. Look at the VR6's bank angle again — 10.6 or 15 degrees. Either is an extremely acute angle compared to most V6 engines which typically have a bank angle of 60 degrees. While 60 degrees is the optimal V6 bank angle for smooth operation and effective packaging, there are a couple of critical reasons why Volkswagen trimmed it down to such a significant degree for the VR6.

At 10.6 or 15 degrees, the distance between the cylinder banks is extremely low, which is beneficial for two reasons. That arrangement means that the VR6 isn't as wide as a traditional V6, making it not only short length-wise, but also very thin. That is a dream in terms of packaging, as it will fit in practically any vehicle and in any arrangement throughout Volkswagen's lineup. Outside of packaging, the distance between the cylinder banks is so small that the VR6 only needs one cylinder head instead of the two usually required for a V6 engine.

The VR6's single cylinder head is a massive benefit for both Volkswagen and enthusiasts, as it significantly reduces the complexity of the engine. While V6 engines require four camshafts — two for each cylinder bank — the VR6 only needs two, just like an inline-six engine. The simplicity of the VR6's cylinder head and valvetrain make it a cheaper engine to manufacture, and an easier engine to work on than a standard V6.