Is A Wankel Engine Different From A Rotary Engine? Here's What You Need To Know

A Wankel engine is a type of rotary engine, but not all rotary engines are Wankel engines. Wrapping your mind around this idea will help you to better understand the similarities as well as the differences between Wankel engines and other types of rotary engines. How a rotary engine works can be better understood when it's called a "pistonless rotary engine." This eliminates the confusion with the similarly-named rotary engines that had pistons in a radial configuration. These were widely used to power airplanes, as well as a few motorcycles and cars. The limitations of this design made it obsolete by the early 1920s.

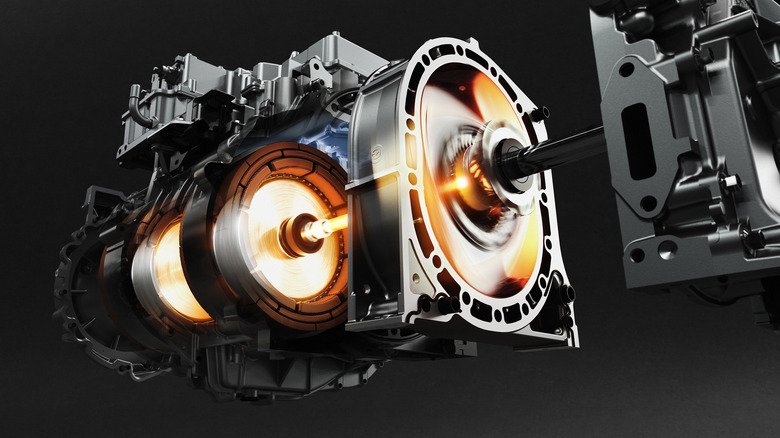

Pistonless rotary engines are the engine family to which the Wankel engine belongs. These engines do not use reciprocating pistons that travel back and forth within a cylinder. Instead, they use a constantly rotating element that spins within a housing into which the fuel-air mixture is injected, compressed, ignited, and exhausted to produce power for the vehicle. The constant, unidirectional movement of this rotating "piston" promises higher efficiency and power, less vibration and complexity, and more power output for a given sized engine.

While there have been many attempts to develop and commercialize pistonless rotary engines, there are only two versions that have had any degree of real success outside of a lab: the Wankel engine (more on that below) and the more recent LiquidPiston engine, which received its first funding in 2007 and is currently involved in testing programs with the U.S. Armed Forces.

The history of the Wankel rotary engine

The creation of the Wankel engine goes back to 1919, when the then-17-year-old Felix Wankel allegedly had a dream about inventing a new type of engine. Even though Wankel had absolutely no formal engineering training, he started his own research lab five years later to develop his "dream" engine. World War II approached and Wankel became a member of the Nazi Party, gaining funding for his rotary engine work for aeronautical applications.

Post-war, Wankel was imprisoned briefly but was later able to partner with German auto and motorcycle producer NSU in 1951, where he continued his rotary engine research and development. His first rotary-piston engine was designed in 1954 and underwent testing in 1957. Wankel's engine featured a piston that was an equilateral triangle with curved edges, rotating within an epitrochoidal housing that looked like a vertically-oriented oval pinched in at the three o'clock and nine o'clock positions.

In 1959, NSU announced its new Wankel rotary engine and saw intense interest from around 100 companies located all over the world. NSU was the first manufacturer to bring the design to market in 1964 with the rotary-engine-powered NSU Spider. The company followed up with the Ro 80 Sedan in 1967, but subsequent warranty issues with the rotary piston's apex seals put an end to NSU's further use of the rotary engine.

Mazda believed in the potential of the rotary engine

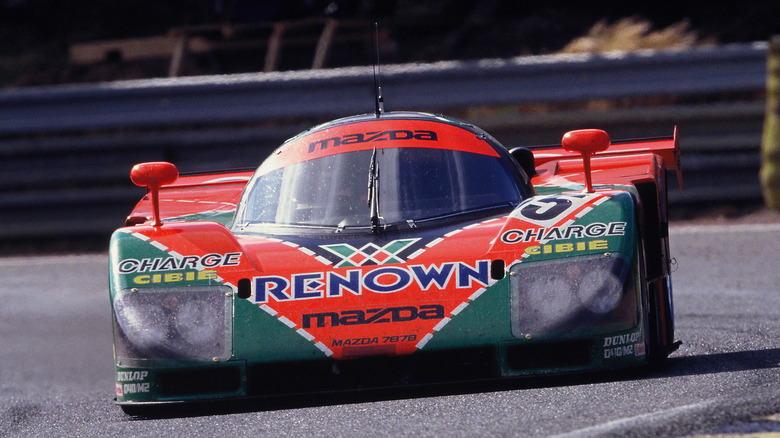

Mazda was an early and steadfast proponent of the Wankel engine. It signed a development contract with NSU in 1959 and displayed its 2-rotor and 4-rotor Wankel engines at the 1964 Tokyo Motor Show. The company's first rotary-engined vehicle was the 1967 Cosmo 110S, followed by a wide variety of cars, trucks and even buses equipped with the rotary. Mazda was able to overcome the apex-sealing issues that caused NSU to shut down its Wankel engine program. The 1970s saw Mazda bringing many affordable rotary vehicles to the U.S. These included the RX-2, RX-3, RX-4, and the much-loved RX-7 and RX-8 sports cars. Mazda also won overall at the 24 Hours of Le Mans race in 1991.

Though Mazda produced some of the best cars with rotary engines, the company hit a rough patch with the fuel crises of the 1970s. While Mazda's vehicles were renowned for their light weight and high performance, their rotary engines suffered from poor fuel economy. With gas prices rising, this became a liability.

Another major problem for Mazda's rotary engines was their poor emissions performance. Poor thermal efficiency led to unburned fuel in the exhaust, oil was injected into the engine to lubricate it (and came out with the exhaust), and rotor seals couldn't seal perfectly because they had to operate at the varying temperatures found within the rotary engine housing. All these issues contributed to excessive emissions. Increasingly strict emissions standards made it impossible to certify rotary-engined Mazdas for sale. The final Mazda RX-8 was produced in Japan in June of 2012.

Are Wankel rotary engines still made?

Mazda has not given up on the rotary engine but is repurposing it for modern electric vehicles. The Mazda MX-30 e-SKYACTIV R-EV plug-in hybrid comes with a 0.8-liter (830cc) rotary engine. With direct fuel injection and exhaust gas recirculation to keep emissions under control, the rotary engine serves as a significant range extender, allowing the MX-30 to cover around 373 miles (600 km) on a single charge and tank.

Mazda also continues to make replacement parts as well as complete replacement engines for its 13B series of rotary engines at its Powertrain Production Department No. 2 in Hiroshima, Japan. The parts are made with the original machinery that produced them during the heyday of the rotary and assembled by some of the original craftsmen who made them in the past. These experts pass down their knowledge to new employees who also have a passion for the rotary engine.

The LiquidPiston engine mentioned previously is not strictly a Wankel engine (it is a rotary engine), but it reimagines the Wankel while eliminating many of its shortcomings. It is currently being evaluated by the U.S. military for use in future aerial drones.