Blue Origin's BE-4 Vs. SpaceX's Raptor Engine: What's The Difference Between Them?

The rise of the commercial space industry in the past decade has been nothing short of amazing to watch. Not only have we witnessed some brilliant innovations brought to reality, such as reusable rocket boosters, but access to space is now cheaper than ever before thanks to the likes of SpaceX and Blue Origins. The private sector has achieved some remarkable feats, such as sending the first commercially-operated mission to the International Space Station (ISS) in 2020 with SpaceX's Crew Demo-2 mission. Although the near-future plans involve returning humans to the Moon, the ultimate goal for many of these companies lies much farther — Mars.

For Blue Origin and SpaceX, in particular, their Martian ambitions hinge on two key vehicles: New Glenn for Blue Origin, and Starship for SpaceX. These heavy-lift launchers can propel cargo and astronauts on many trajectories — from Low Earth Orbit (LEO) to Mars — at costs far lower than anything we've ever built before.

There are many reasons behind the affordability, from advanced manufacturing techniques to reusable technology. But arguably, the true game-changers are in the engines that power these spacecraft — the Blue Engine-4 (BE-4) and Raptor. Compared to more "conventional" rocket engines, BE-4 and Raptor are cheaper, more efficient, environmentally friendly, reusable... basically better in every single way than the engines we've relied on to go to space in the past.

[Featured image by SpaceX via Wikimedia Commons | Cropped and scaled | Public domain]

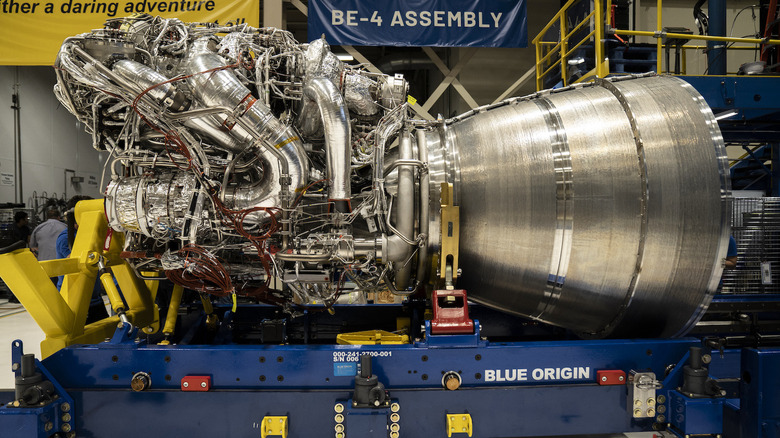

What is the Blue Origin BE-4 engine?

The story of the BE-4 engine began in 2011 when Blue Origin (BO) partnered with United Launch Alliance (ULA) to develop a new class of powerful engines. Their ambition? To build a new American orbital-class rocket within the decade. After three years of quiet development, the company finally unveiled the specifications of its new engine in 2014. Initially, the engine was only supposed to power BO's New Glenn rocket. Later, BO entered a deal with ULA to supply BE-4 units to its next-generation Vulcan Centaur rocket, too — which made its maiden flight in January.

The BE-4 is a single-shaft, oxygen-rich staged-combustion engine. That's a lot of technical lingos that, through the course of the article, we'll break down one by one since it's in these hyphenated technical terms that the true differences between the BE-4 and the Raptor lie. All you need to know for now is that the BE-4 combusts its propellants in stages to provide better fuel efficiency.

At sea level, the BE-4 can generate 550,000 pounds of thrust force. To put that into perspective, the much smaller BE-3 engine that powers BO's suborbital New Shepard rocket produces only about one-fifth of that thrust, or around 110,000 pounds at sea level. This makes it, at the moment, one of the most powerful engines in the world and the second most powerful Methalox-fueled engine around ... second only to the SpaceX Raptor 3 engine.

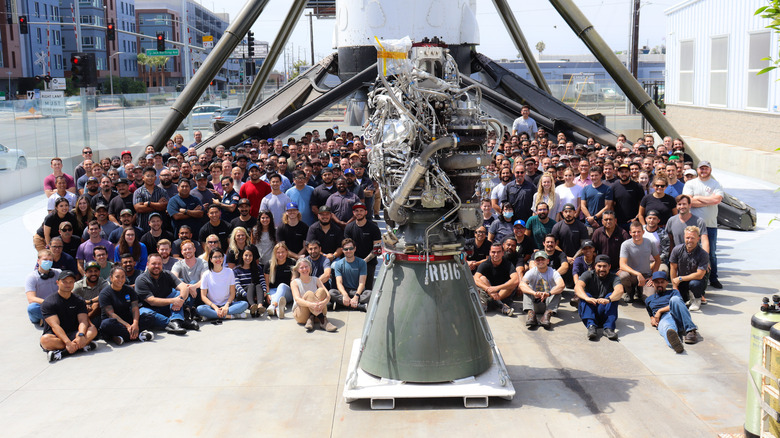

What is the SpaceX Raptor engine?

In 2012, SpaceX announced its plans to produce a Methalox rocket engine that would be several times more powerful than the kerosene-burning Merlin engines powering its workhorse Falcon 9. The main reason SpaceX chose a methane-fueled engine wasn't really about efficiency. Rather, it comes from a more practical consideration: methane is plentiful on Mars, which is the final destination of Starship.

This will allow astronauts to produce rocket fuel on-site rather than solely relying on supply missions from Earth. Of course, methane has other upsides than just being plentiful off-world, too; like how it doesn't produce much soot, which can clog up the injectors of a rocket engine like a kerosene-based propellant would.

Like the BE-4, the Raptor uses a staged combustion scheme to achieve better fuel efficiency. However, the Raptor has a full-flow, twin-shaft configuration. This means the Raptor has double the number of pre-burners, each driving a single propellant pump. What SpaceX got out of this design is greater reliability and safety.

The downside is that the engine is also far more complicated to build. Thankfully, over the years, SpaceX has simplified and iterated on the engine with each hot-fire test. Today, the latest version of the Raptor (Raptor 3), isn't just cheaper than the first one, it also has nearly 50% the nominal thrust — increasing from 408,000 pound-force at sea level on the Raptor 1, to almost 593,000 pound-force on the Raptor 3.

The staged combustion cycle

For a liquid-fueled rocket engine to work, you need to pump the fuel and oxidizer into the combustion chamber at the right quantity, pressure, and ratio. Handling this task is a turbopump, which requires a lot of power. In a modern staged combustion engine, this power is generated by what's called a pre-burner. Take the BE-4 engine, for example: It has a single pre-burner mounted on a shaft that drives both the oxidizer and the fuel pumps.

When the engine ignites, the oxidizer pump routes a full flow of oxidizer through the pre-burner. Simultaneously, a small amount of fuel is introduced to create combustion and fire up the pre-burner. The resulting hot gas runs a turbine that powers the turbopump and, via piping, travels to the main combustion chamber. The oxygen-rich gas is then mixed with more fuel, combust, and boom — thrust.

While the BE-4's design is relatively simple, it has its downsides. For instance, extra sealing is required to prevent the oxygen-rich gas from "leaking" back through the fuel line and prematurely igniting. This sealing makes the engine more maintenance-intensive. This is where Raptor's full-flow staged combustion (FFSC) design comes into play. Instead of just one pre-burner, the Raptor has two: an oxygen-rich pre-burner for the oxidizer pump and a fuel-rich pre-burner for the fuel pump.

Since these two systems are separate, there's no need for sealing. This makes it more durable by design, which is a crucial requirement for a one-way trip to Mars.

Thrust level

When Blue Origin announced the BE-4 in 2014, they announced that it was the most powerful Methalox-burning engine ever conceived. Compared to the first version of the Raptor, which was the only other functioning Methalox engine at the time, it was true. The BE-4 can output a lot more power at 550,000 pound-force at sea level versus the Raptor 1's 408,000 pound-force.

Two BE-4 cores make up the first boosting stage of ULA's Vulcan Centaur rocket and together (with no side boosters), the system can bring about 23,800 pounds to low Earth orbit, or fling 5,100 pounds to the Moon. It's a feat that it would've achieved had the roughly 2,800-pound Peregrine lunar lander that the Vulcan sent to space on January 8 hadn't malfunctioned and careened into the Pacific Ocean after six days.

However, while the design of the BE-4 has remained largely unchanged since its conception point in 2011, the Raptor series has gotten to its third iteration. The Raptor 3 — the latest version — was a complete redesign of the engine to make it smaller, more streamlined, reliable, and most importantly, offering more thrust. The Raptor 3 can deliver up to 593,000 pound-force of thrust, making it by far the most powerful Methalox engine ever. With 33 Raptor cores powering the Super Heavy first stage of Starship, SpaceX's massive launch system can bring up to 330,000 pounds to orbit, dwarfing Vulcan's best by nearly five times.

Specific impulse

Efficiency is everything in rocketry, which is why specific impulse (Isp) is such a big deal in this field. Simply put, this number represents the amount of thrust an engine can generate when burning a certain amount of propellant over a set period — typically in seconds. The higher the Isp of a particular rocket engine, the more efficient it is since it can produce more thrust, while consuming less fuel.

According to measurements made by Everyday Astronaut, the Isp for the BE-4 sits at around 310 seconds, while the initial version of the Raptor goes up to 330 seconds. The 20-second difference may not sound like much for most of us, it's actually very important for a rocket engine.

Basically, when you attach the two engines to the same rocket, each carrying an equal amount of propellant, the Raptor will be able to burn for 20 extra seconds compared to the BE-4. So, even if the total thrust of the Raptor 1 (around 450,000 pound-force) is less than that of the BE-4 (550,000 pound-force), the fact that it's able to produce thrust for 20 extra seconds could allow the Raptor to bring more mass to orbit than the BE-4.

Which engine is better in the end?

The engineering behind both the BE-4 and Raptor engines is mind-boggling and both are, without a doubt, industry-leading. But if you were to take a look at all the details between the two, it's clear that the SpaceX Raptor is currently enjoying a big edge over the BE-4 in just about every respect. The latest iteration of the Raptor isn't just more efficient than the BE-4, but it has also proven itself in real, hot-fire tests to achieve a higher peak thrust than its rival.

There's also the matter of availability. SpaceX is churning out one Raptor engine core per day at their in-house manufacturing plant in McGregor, Texas. Meanwhile, the BE-4 has (infamously) encountered troubles during development and production, resulting in a four-year delay in the engine's launch. In fact, it was because of all the issues surrounding the BE-4 that ULA had to postpone the launch of their flagship Vulcan rocket several times. And since the Vulcan's maiden flight in January, it has been the only time the BE-4 has been used in a realistic launch mission so far.

As for the Raptor? It performed brilliantly in the last few tests of the Starship system. At the time of writing, the next Starship launch test has been announced. Unless Blue Origin comes up with new upgrades for the engine, the capability gap will only widen as SpaceX improves on its engine design further.