10 Weird Attempts To Reinvent The Wheel (Literally)

The car is one of the most important creations ever. Automobiles reinvented transportation and even associated industries — we wouldn't have the assembly line if it weren't for cars. Quite frankly, the only invention more influential than the car is the wheels they rely on.

Wheels have been around since at least 3500 B.C.E. and have undergone relatively few changes. First builders started hollowing out solid wheels and supporting them with spokes, then they added items such as rubber rings (i.e. tires) to the outsides for extra durability and traction. However, the core principle and shape of the wheel have remained unaltered for thousands of years, so much so that people have generally given up trying to create a better method of transportation. In fact, the idiom "reinventing the wheel" describes working hard to create an alternative to something that has already been perfected. But if that expression were true, then the tank's treads and the hovercraft's inflatable balloon wouldn't exist. Turns out wheels aren't universally efficient in all situations — and there's always room for improvement.

Here are some crazy ideas engineers and designers have come up with to alter how wheels function, if not supplant them entirely.

Spherical Tires

Wheels can rotate a full 360 degrees, but they can only go in one direction. You can turn them to alter your vehicle's direction, but not by much. Goodyear tried to fix this issue by using the only object rounder than a circle.

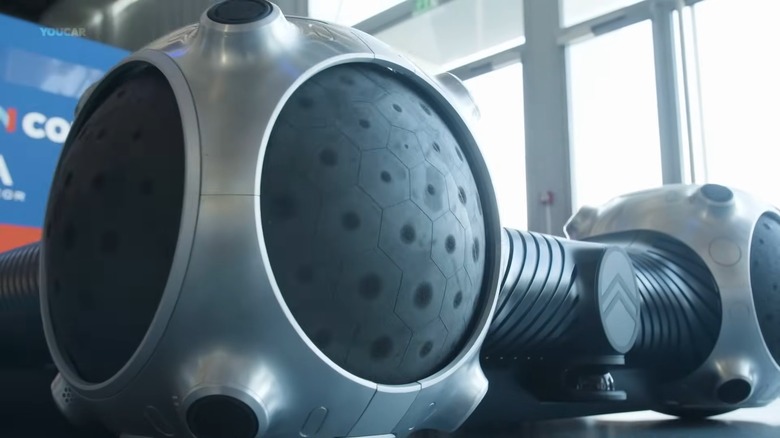

In 2016, Goodyear unveiled the Eagle-360, a spherical tire with treads that mimic the texture of brain coral. One might wonder how glorified dodgeballs could ever be considered tires. The answer is magnetic levitation (MagLev) technology. Eagle-360 tires can rotate and brake using varying magnetic fields, which means drivers would never have to worry about wearing down brake pads. Since the Eagle-360 is spherical, they are, as Popular Mechanics put it, "essentially omnidirectional." Any cars that use these wheels could drive forward and backward, strafe, and spin in place. This design would make swapping lanes easier and let cars squeeze into parking spots without much effort. It would also eliminate the need for traditional parallel parking maneuvers.

While the Eagle-360 hasn't entered production just yet, in 2021, the French car manufacturer Citroën unveiled the conceptual Citroën Skate, an autonomous universal platform that runs on Eagle-360 tires and can connect to modular pods. Imagine a world where instead of public transportation, everyone owns their own pod and rents out Citroën Skates like an Uber. Once you're done using one, it detaches and moves on to the next person. That hypothetical future might become the present if the Eagle-360 gets off the ground.

Archimedes Screw

The Archimedes screw is a deviously simple, gravity-defying device that consists of a pipe with a helix wrapped around it, which resembles the thread of a screw. This invention has been used to raise water from one location and deposit it elsewhere ever since the days of Ancient Egypt, if not longer. Archimedes screw vehicles, alternatively known as screw-drive vehicles, harness the same principle the Archimedes screw relies on. But instead of staying still and transporting material up its helix, a screw drive propels the attached vehicle forward. Archimedes screw vehicles are generally amphibious and best used in muddy, snowy, and swampy areas.

The first example of an Archimedes screw vehicle can be traced back to the late 1800s. Jacob Morath patented an agricultural machine that would use Archimedes screws to travel across farmland while also tilling soil and breaking up roots. However, this vehicle was never manufactured. The screw drive didn't see any actual action in the real world until the early 1900s when James Peavey patented his own contraption — the screw-drive vehicle. Probably the most famous example of an Archimedes screw vehicle was the ZIL-2906. While it looked like it could run through walls, it was primarily used to search for and retrieve Russian cosmonauts.

While you don't see Archimedes screw-powered vehicles often anymore, they are still used in a few niche roles, such as mud farming and arctic exploration vehicles.

[Featured image by Mil.ru via Wikimedia Commons | Cropped and scaled | CC BY 4.0]

Transforming Wheel Track

Wheels excel on solid roads, but sometimes they have trouble gripping the surface — assuming there's even a "surface" and not just sand or mud. Caterpillar treads tend to shine in the latter scenario, but their paved road performance lags behind wheels. It's a shame you can't use a vehicle that shifts between wheels and treads depending on the road conditions. Or can you?

In 2018, the Defense Advanced Research Projects Agency (DARPA) revealed the fruits of the Ground X-Vehicle Technologies (GXV-T) program, which consisted of projects meant to improve military vehicle survivability without weighing them down with armor. The Carnegie Mellon University's National Robotics Engineer Center's contribution was the reconfigurable wheel track (RWT). The RWT could shift from a rolling round wheel to a tumbling triangular tread in under two seconds — even while attached vehicles were on the move. The device was meant to optimize vehicle mobility over rapidly shifting terrain and ensure its attached car or truck sped along as quickly as possible.

DARPA and Carnegie Mellon weren't the only think tanks to come up with rapidly-transforming tires. Seoul National University's Biorobotics Lab and Harvard's School of Engineering and Applied Sciences also collaborated to develop their own transforming wheels, but instead of creating pliable tank treads, their project result was essentially metal origami. This particular model couldn't turn into rubberized caterpillar treads, but it could shift from long, drum-like rollers with smooth rims to tall, ridged wheels intended for rough terrain.

While you probably won't find transforming wheels on your average consumer Honda or Toyota, they might become a common sight on military vehicles, armored or otherwise.

Universal Wheel Drive System

While the shape and function of the wheel have remained unchanged for thousands of years, the mechanics have evolved by leaps and bounds. Car wheels aren't just tires, spokes, hubs, and axles — they also require components that sit outside the wheel proper. However, some engineers recently unveiled a new type of wheel that is a little more self-contained.

In 2023, Hyundai and Kia revealed what they called the Universal Wheel Drive System, or Uni Wheel for short. At first glance, the Uni Wheel might look like any other car wheel, but the magic waits just under the surface. Unlike most car wheels, which rely on drivetrains that extend outward and into the engine, the Uni Wheel's drivetrain sits inside the wheel.

In normal wheels, a reducer trades motor rotation speed for torque — the drive shaft sends that torque to the wheel, and the constant-velocity Joint (CV Joint) ensures power transfer is constant from the engine to the wheel. The Uni Wheel combines these three primary components (or at least their functions) into a sun gear, a series of pinion gears that form a linkage assembly, and a ring gear. This design frees a ton of space that can be used for extra legroom or trunk capacity, especially because the Uni Wheel allows engineers to split electric vehicle engines into two separate motors.

Since Hyundai's and Kia's engineers created the Uni Wheel with electric vehicles in mind, it's difficult to predict if the design will ever find a home in combustion engine models. Nevertheless, the Uni Wheel could easily revolutionize electric vehicle floor plans, if only because it allows designers to add more floor space to car blueprints.

e-Corner Wheels

Nobody likes parallel parking. Sure, plenty of people can pull off the maneuver no problem, but it's still annoying to do, especially when it's a tight squeeze. Luckily, Hyundai is working on a car that should solve that problem. During the Consumer Electronics Expo 2024, the company introduced the MOBION, which is a stock IONIQ 5 with one key difference: the e-Corner System. According to a firsthand report from The Verge, this system is activated by the touch of a button (on the car's touchscreen tablet), which activates several special driving modes that let the MOBION spin in place, pivot the rear, and strafe.

You might wonder how the MOBION can accomplish this. At first glance, it seems like the wheels only turn almost full 90 degrees and then spin in different directions depending on the specified maneuver. But the e-Corner System goes far deeper. Each wheel has its own independent drive motor, suspension, steering motor, and brakes — no axles or steering linkages. Since each MOBION wheel is its own motor, you'll probably never see a car with a combustion engine utilizing the e-Corner System.

Unlike most wheels on this list, the MOBION isn't a concept. The head of advanced engineering at Hyundai Mobis, Vice President Lee Seung-Hwan, said the MOBION and its wheels are "ready for immediate mass production." The car will probably cost more than most houses, but you might be able to purchase the MOBION before the decade is over.

Mecanum Wheels

While many wheels and tires have patterns (i.e. treads) that help them grip surfaces, these "additions" don't mess with the wheel's overall round shape. You want to keep them rolling straight — unless you intentionally design a wheel with add-ons that completely change how they move.

Mecanum wheels are a special form of omnidirectional wheel invented by Bengt Erland Ilon. Unlike most wheels, which sport either smooth(ish) surfaces or textured tires, the rim of the mecanum wheel is covered in rollers — usually rubberized — that are placed at 45-degree angles. Contrary to what you might think, this design does not hamper the wheel's ability to roll forward or backward. If anything, these rollers free up vehicle movement.

Thanks to the mecanum wheel's rollers, vehicles can travel in any direction by altering the direction each wheel spins. For instance, if you want to go forward, you make all wheels spin normally. But if you want to spin on the spot, you make the wheels on the left turn in one direction and the wheels on the right turn in the other. Strafing is also possible by spinning the front left and rear right wheel one direction and the front right and rear left in another.

While we're probably a long way away from seeing cars sporting mecanum wheels, forklifts and robots are built with these unique models when movement space is at a premium. And if you want a mecanum wheel-powered vehicle of your own, you can always build one.

[Featured image by Euchiasmus via Wikimedia Commons | Cropped and scaled]

Moss-Filled Wheels

Air quality is a constant concern in cities due to heavy usage of cars and motorcycles and not enough plants. Phasing out components such as two-stroke engines has helped, but that hasn't addressed the dearth of vegetation. Recently, though, some engineers penned the brilliant plan of adding plants to cars, and we don't mean just putting a succulent in the cup holder.

During the 2018 Geneva International Motor Show, Goodyear unveiled the Oxygene. This concept wheel should function like any other wheel but with a twist: The wheel's sidewall would be filled with moss, and the tire's open design would let moisture and water seep into the tire and circulate throughout the moss to keep it alive and breathing. According to Goodyear's calculations, if every vehicle in a city the size of Paris replaced their regular tires with Oxygenes, we'd be looking at 2.5 million cars pumping out almost 3,000 tons of oxygen and absorbing over 4,000 tons of carbon dioxide per year. And since the tires would be open, drivers wouldn't have to worry about punctures. Two birds, one mossy stone.

The Oxygene's sustainable design is intended to be future-proof. According to President of Goodyear Europe, Middle East and Africa Chris Delaney, over two-thirds of the Earth's population is expected to live in cities by 2050. Yet the World Health Organization (WHO) reported in 2016 that over 80% of people who live in urban environments don't have access to sufficiently clean air. Drivers who adopt Oxygene tires would cleanse the oxygen as they drive, and that isn't the wheel's only pollution solution — they would also be constructed out of recycled tires.

Even if the Oxygene never makes it to production, here's hoping someone else manufactures oxygen-producing wheels. The less pollution we have to breathe in, the better.

Light-Up Wheels

The Mercedes-Benz Vision AVTR and Lincoln Model L100 are both concept cars that embody what their respective designers think cars will look like in around 100 years. While their forms look nothing alike, they still share many design tropes — automatic, handleless doors; electricity-powered engines; and for the purposes of this entry, light-up wheels.

At first glance, the Vision AVTR's and Model L100's wheels are just cosmetic. The AVTR tires look like rolling rubber armadillos with luminescent bands, whereas the L100 doesn't even show its tires — the "wheels" are part of the car's body, and the lights mimic their shape. However, neither car's wheel lights are mere fashion statements. Since the AVTR and L100 are electric vehicles, their wheels also function as charge indicators and show whether the batteries are full or still need a bit of juice. Moreover, AVTR's wheel lights act as turn signals — people driving beside you get a helpful shine of yellow lights when you want to merge into their lane.

Cars probably won't look like the Vision AVTR or Model L100 in the next 100 years, but their light-up wheels hold promise. Many devices with rechargeable batteries feature lights that let owners know if they're fully charged. Who wouldn't want that on an electric vehicle, especially if it doubles as a turning signal? You can never have too many road safety features.

Electricity-Generating Wheels

Electric vehicles have a lot of promise, but they're held back by several things, namely their range and a general lack of charging stations. Solar panels are a potential solution, but Goodyear came up with another idea: Tires that charge your car as you drive. In 2015, the company announced the BH-03, a concept tire that converts energy into electricity. According to Wired, Goodyear's pitch would see the BH-03 generate electricity in one of two ways: thermoelectricity or piezoelectricity.

The former is self-explanatory. Tires heat up when they're in the sun and spinning on roads (there's a reason people say they're "burning rubber" when speeding). Using materials such as bismuth telluride and tin selenide, a tire could convert that heat to electricity. Piezoelectricity, meanwhile, is the production of electricity in response to mechanical stress, and tires are under constant stress since they deform while spinning. Materials such as quartz can convert these pressing and squeezing forces into electricity.

What's the possible use of an electric-generating tire, you ask? In theory, it could send the electricity it generates from heat and/or stress to the car battery. This doesn't mean Goodyear has the keys to an infinite energy cheat for electric vehicles, but the BH-03 could potentially keep them charged far longer than normal. Still, Wired says Goodyear has to work out countless logistics problems before it can start producing the BH-03. What materials produce as much electricity as possible without sacrificing durability? How efficient will these materials be? How would they even be implemented into the standard tire design? By Wired's calculations, we probably won't see the BH-03 in action until 2025 or 2030 at the earliest.

Regrowing Tires

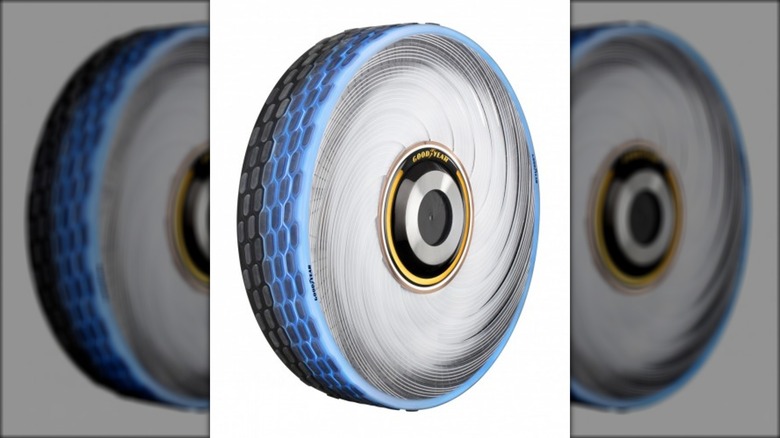

Tires are durable, but they aren't immune to the punishing conditions of rotating thousands of times per minute over hard asphalt. For this reason, some engineers are toying with the idea of tires that never need replacing (this isn't the same as making invincible tires, though). In 2020, Goodyear announced the reCharge — a striking concept tire that, like the Oxygene, would be sustainability-forward. The core design of the wheel revolves around its construction material. Unlike other tires, the reCharge would utilize a biodegradable tread compound that would start as a liquid inside a capsule and slowly regenerate the tire as roads wear it down.

The reCharge's material wouldn't just reduce polluting waste — its biological nature would make it easily sourceable. And the previously mentioned capsule would act as the tire's secret sauce. In Goodyear's pitch, replacing the reCharge tire would be as easy as swapping out capsules. Moreover, the wheel tread would be supported by a lightweight, non-pneumatic frame. In layman's terms, you'd never have to worry about tire pressure again.

Even if the reCharge doesn't come to fruition, many parts of the design deserve a shot. While a regenerating tire would do the world a huge service, a biodegradable tire formed out of biological materials is probably the most appealing feature. You can't reinvent the wheel quite like making rubber tires obsolete.