America's New 6th-Gen Fighter Jet Will Most Likely Be Equipped With This Cutting-Edge Engine

It's an open secret that the U.S. military is actively developing a new fighter jet more advanced and capable than its cutting-edge F-35 Lightning II. Known as the Next Generation Air Dominance (NGAD) program, there has been much speculation about its capabilities and the weapons it can carry. However, amidst all the exciting discussions, one crucial element is often overlooked: What engine will keep it flying?

From the outset, advanced propulsion has been a key part of the NGAD program's goal. The chosen engine must provide a significant leap in capability compared to its predecessors, offering higher, more efficient thrust, increased cooling, and power generation, all while being more durable and reliable than any engine currently in the U.S. inventory.

It's a tall order, but one that the Air Force deems urgent enough to award five veteran engine manufacturers – Boeing, General Electric, Lockheed Martin, Northrop Grumman, and Pratt & Whitney – a $975 million contract each to develop an engine design that can meet all the requirements by the 2030s. This effort is part of a sub-program of NGAD called Next-Generation Adaptive Propulsion (NGAP).

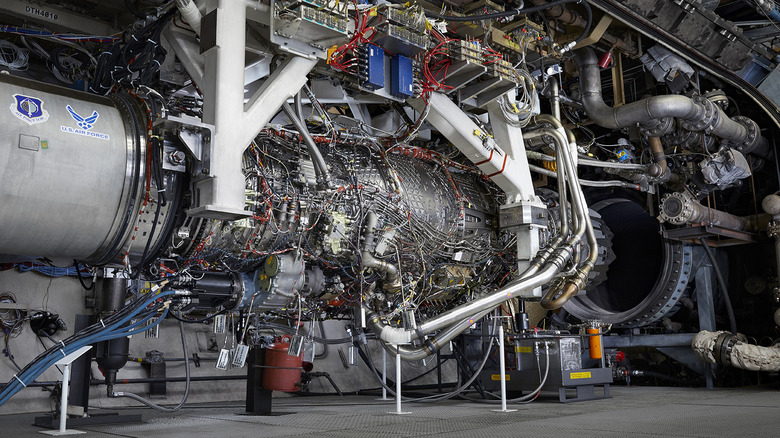

Fortunately, we don't have to wait for long to get a glimpse of what such an engine might look like. GE Aerospace has unveiled its XA100 engine, while Pratt has also published details about its XA103 prototype. But what makes these engines so special?

What Is an Adaptive Engine?

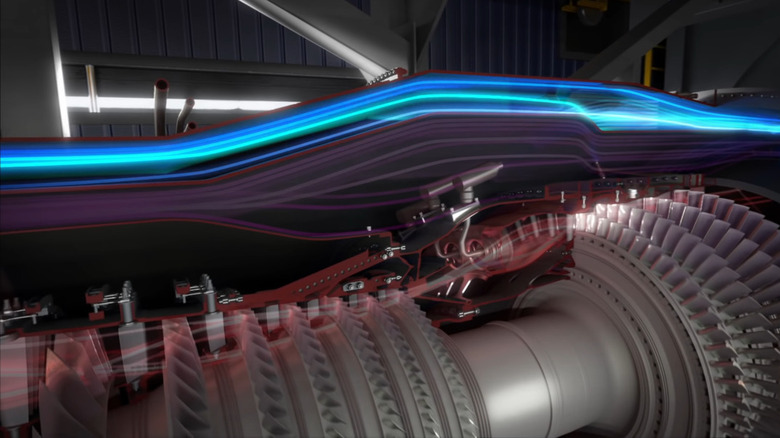

Traditional jet engines, both civil and military, are known as two-stream turbofans. When air flows into the engine's inlet, it is divided into two separate streams: the core stream and the bypass stream. The core stream flows directly into the engine's core, where it is mixed with fuel, combusted, and expelled as a hot, high-velocity jet. The other stream, known as the bypass stream, is directed around the engine's core and accelerated by the hot gas, providing additional thrust. The disparity between these two airstreams is referred to as the engine's bypass ratio.

High-bypass engines are typically used in commercial airliners. While they provide comparatively lower power, they are extremely fuel-efficient, especially at subsonic speeds, making them great for cheap mass transportation at scale. Military fighter jets, on the other hand, prefer low-bypass engines. With more fresh air flowing through the engine's core, these engines can provide much higher thrust, better performance at supersonic speeds, and enable the use of an afterburner. In exchange, fighter jets are notoriously fuel-hungry.

Adaptive engines like the XA100 and XA103 are designed to combine the best of both worlds into a single package. They can reconfigure themselves in mid-flight to better suit the flight profile. For instance, when the jet is cruising at subsonic speed, the engine can be optimized for maximum fuel efficiency and range. In combat situations, it can adapt for maximum thrust and supersonic performance, just like a conventional fighter jet engine.

How the XA-series Engines Are Different

XA-series engines follow the same concept of operation: they can "adapt" themselves by utilizing a third stream of bypassed air, instead of the conventional two-stream design. In subsonic cruise, the third stream is allowed to flow near the exterior of the nacelle, around the core block. This enlarges the engine's bypass ratio and, consequently, improves fuel economy. In supersonic flight or combat situations when thrust takes precedence over efficiency, the adaptive fan can "focus" the third stream inward and through the core, resulting in a narrower bypass ratio and extra thrust.

Many components in these engines are fabricated from ceramic-matrix composites (CMCs), which are more durable and can withstand higher temperatures while being lighter than common aero-grade metals. CMCs allow the engine to run hotter, making it more efficient since less air has to be diverted to cool the engine. Additionally, 3D printing technology is employed, which can help lower costs and improve the engine's serviceability.

The third airstream also plays a crucial role in cooling by acting as a heat sink. Besides cooling electronics, it allows the jet to fly at near-supersonic speeds at lower altitudes for longer periods without burning up due to the increased friction with denser air.

Lastly, the kinetic energy of the third stream can be harvested by an accessory drive to produce electricity. As much as one megawatt can be generated in this fashion, which can, in turn, be used to power future laser weapons.

The XA100-series Is Cruising Along Nicely

Originally, the Air Force planned to immediately press adaptive engines into service by swapping out the F-135 engines of the F-35 with the new XA-series powerplants. However, the total costs to re-engine the nearly 500-strong fleet of F-35s of different variants across all branches were deemed too expensive. Fortunately, these revolutionary engines wouldn't be mothballed — they would be held off and further developed to power the next generation of American fighter jets. Instead of receiving a brand-new engine architecture, the F-35 will simply have its F-135 engine upgraded to provide more performance and better thermal management via the Engine Core Upgrade (ECU) program.

In March, lawmakers set aside $280 million for Pratt & Whitney and GE Aerospace to continue maturing the technology and push them closer to production. So, when you look at the prototypes of the XA-series engines on their test stands, you're most definitely witnessing the future of American airpower (or part of it, at least).

Currently, little is known about the progress that either Pratt or GE is making with their respective prototypes, or how they differ and compare to each other. All we know is that according to the companies, tests and reviews are being conducted at a good pace. Regardless of which company ultimately wins, the new engine — once flown — will surely shake up the aerospace industry as a whole!