Do Rotary Engines Have Valves? Here's How They Work

Rotary engines (also known as Wankel engines and Wankel rotary engines) are quite different from piston or "reciprocating" engines. One of the distinguishing features is that they don't need valves to operate. That's to say, the Wankel rotary engine design doesn't have valves — but quite a few rotary engine designs have incorporated them. Both rotary engines and piston engines utilize internal combustion and share the same phases of intake, compression, power, and exhaust. But beyond this similarity, they are very different in design and operation.

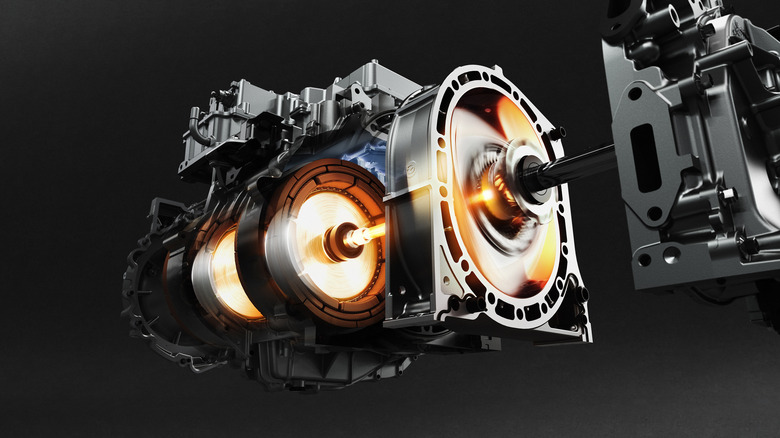

The work done by a rotary engine doesn't need to be converted into rotational motive power for use by propellers or transmission, as is the case with piston engines. As a result, they are considered more efficient by some metrics and require fewer moving parts to function. The first rotary engines were primarily used for aircraft during World War I, but the design was abandoned due to flaws and inefficiencies.

In 1954, German engineer Felix Wankel invented a new design for an automobile rotary engine for the German car and bike company NSU. After prototype testing by NSU in the following years, they entered into an agreement with Japanese company Mazda to develop Wankel rotary engines for its cars. The first Mazda cars with rotary engines were launched in Japan in the 1960s before crossing the Pacific to America in 1971. Remaining one of the few companies that stuck with the rotary engine design, Mazda has, over the years, developed some of the most innovative engines of this type.

How rotary engines work

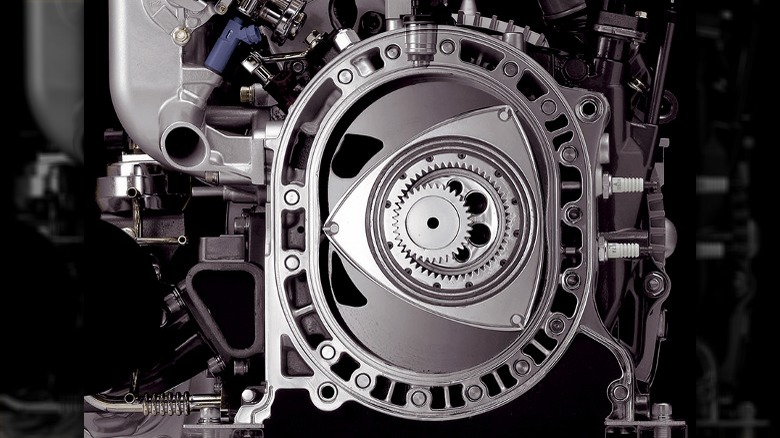

These engines create power by combusting a mixture of compressed air and fuel within a chamber or cylinder, translating the displacement of the rotor or piston into motion. Wankel rotary engines feature an equilateral triangular rotor with convex edges in an ovaloid chamber or rotor housing (the shape is an epitrochoid where the long sides of a symmetrical oval have two curves like a slight figure eight).

As the triangular rotor moves through the chamber, all three of its apexes are in constant contact with the housing (thanks to rotary engine apex seals), creating three gas volumes that are isolated by the rotor. There are two ports on the same side of the figure eight housing, with the top one for intake of fuel and air and the bottom one for the exhaust of combusted gases. Intake can be assisted by a supercharger pushing air into the chamber, while exhaust can be assisted by a turbocharger pulling air out of the chamber.

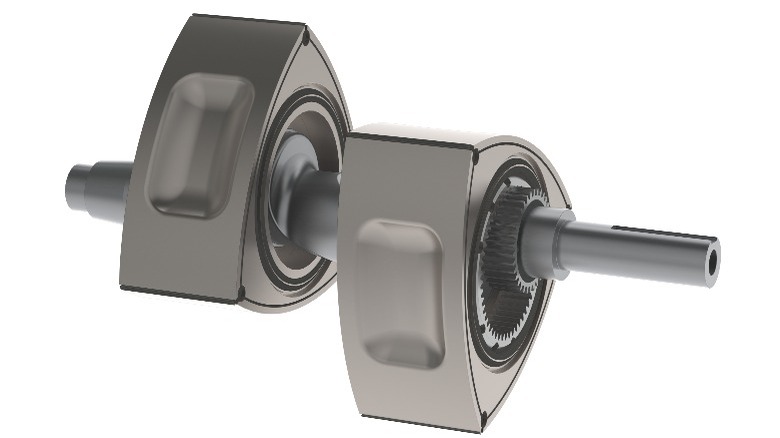

As the leading edge of the rotor passes the intake port, it creates a vacuum, inducing (or pulling) air and fuel into the chamber. The rotor's motion then compresses the air and fuel, lit by a spark plug (two in Mazda's design), further propelling the rotor along its path and sending the combusted gases out of the exhaust port. The rotor is attached to an eccentric output shaft (containing lobes not on the center of the shaft) via a gear, and as it rotates, the shaft produces a torque that's used to turn the transmission.

Do rotary engines have valves?

So far, we've explained the most basic Wankel rotary engine, but Mazda — the company that popularized it — has developed several variations over the years. One improvement included a concave pocket on each of the three convex edges of the rotor, which increased the amount of volume within the epitrochoid housing.

Mazda also attempted to solve one of the biggest problems of the Wankel rotary engine — the incomplete combustion of all the fuel in the air-fuel mixture — by incorporating two spark plugs to combust both compressed air-fuel volumes created within a single cycle of the rotor. In its latest rotary engine design used in the November 2023 Mazda MX-30 Skyactiv R-EV, the Japanese company also changed the location of the fuel intake to the top of the housing, separating it from the air intake, thereby keeping it in the main intake area and increasing atomization to improve the incomplete combustion of fuel.

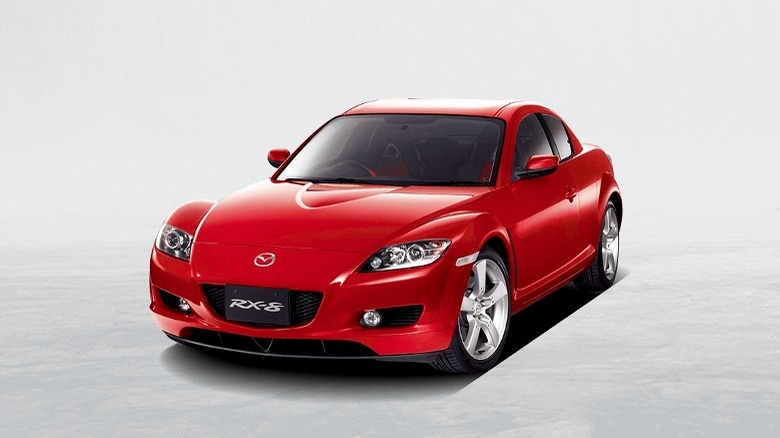

Another Mazda rotary engine innovation is using an auxiliary intake port valve that can swivel open to increase the amount of air during the intake phase when required for more power at higher RPMs. Later designs of the Mazda rotary engine included two more valves for greater air intake when needed at higher RPMs. So, to answer the question, do rotary engines have valves? Yes, they do, including in some of the most popular rotary engines of all time — those used in the Mazda RX-7 and Mazda RX-8.

Differences between a rotary engine and a piston engine

Rotary engines have three power phases instead of just the one of a four-stroke engine. This, along with the way the rotor is mated to the gear of the output shaft, means that for every complete rotation of the rotor, the output shaft rotates thrice, instead of just once, as with a reciprocating piston engine. All four phases occur within a single cycle of the rotor, rather than one at a time in a four-stroke piston engine.

There is also no need for a minimum of two valves (intake and exhaust) per cylinder as seen in a piston engine. Instead, fuel enters via intake ports that don't need to open and close. In a Wankel rotary engine, air and fuel are pulled in by a partial vacuum, and combusted gases are pushed out by pressure. However, various valves have been adopted to deliver variable valve timing for better air intake at different RPMs.

In its simplest form, a Wankel rotary engine has just two moving parts: the rotor and the output shaft. Compare that to modern piston cylinder engines, which have over 40 moving parts. Of course, in many iterations of the rotary engine, Mazda used two rotors rather than one, bringing the total number of moving parts to three. You get at least three more moving parts if you include the extra air intake valves the company added in later years.

Advantages and disadvantages of a rotary engine

Advantages of a rotary engine include its compact size, which makes it lightweight and gives it a higher power-to-weight ratio than piston engines. Its simple design with fewer moving parts makes it easier to produce, and the parts also move slower compared to piston engines, making rotary engines more reliable in terms of wear and tear. A reciprocating engine needs its power translated to rotational motion, whereas the rotary engine produces direct rotational motion, creating much lower vibration, higher RPMs, and smoother power delivery. Rotary engines are also touted for their multi-fuel capabilities, ranging from gasoline to ethanol and natural gas.

Disadvantages of a rotary engine include lower fuel efficiency, increased emissions (thanks to the use of oil — that is combusted alongside the air-fuel mixture — within the housing to better lubricate and seal the rotor), and regular replacement of the seals (apex, face, and side). Rotary engines also have reduced thermodynamic efficiency thanks to the large rotor housing with combustion happening only in certain sections, which leads to different temperatures of the housing, causing uneven expansion and difficulty in maintaining a seal. Mazda has attempted to solve the fuel efficiency problem by changing the location of the fuel intake. In recent rotary engine designs, the company uses aluminum for the interior of the housing instead of iron for additional weight loss. It also aimed to solve thermal and fuel efficiency problems by using exhaust gas recirculation (EGR).

Popular vehicles with rotary engines

Mazda is one of the only automotive companies that has commercially used rotary engines, starting with the Cosmo Sport (also known as the 110S) in 1967. Other popular rotary engine-powered vehicles by the company include the Mazda Luce R130 Coupe, the Rotary Pickup, the Parkway Rotary, the RX-7, and of course, the RX-8. An honorable mention is the Mazda 787B, a Group C sports prototype racing car that won the 1991 24 Hours of Le Mans race. It remains the first-and-only car that didn't use a reciprocating engine to win the 24 Hours of Le Mans race.

The latest rotary engine car from the Japanese manufacturer is the Mazda MX-30 Skyactiv R-EV, released in November 2023. Its launch marked Mazda's first rotary engine offering since it discontinued the Mazda RX-8 in 2012. To be precise, however, the MX-30 Skyactive R-EV uses its small, single-rotor rotary engine as a range extender and not to actually power the drivetrain.