The Best And Worst Years For The Jeep 4.0L Engine

Jeep, as the brand we know today, was first established by Willys Overland after it produced the company's Quad vehicle for the U.S. Army during World War II. In the years since, Jeep has passed into the hands of Kaiser American Motors and Chrysler, with its 4.0L engine design amongst the most sought-after and reliably bought models.

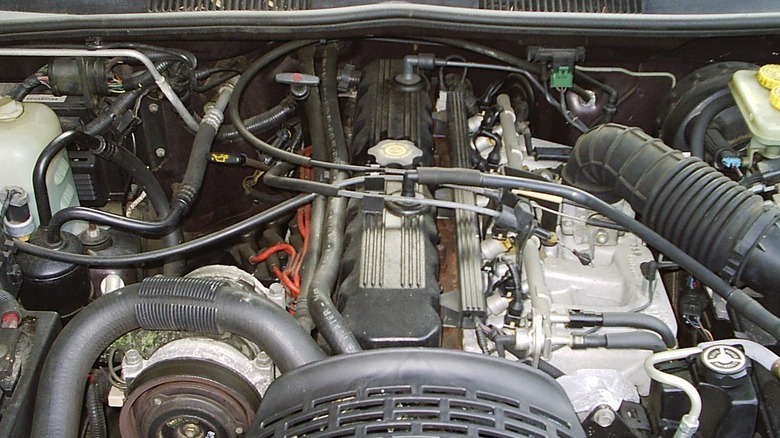

One of the many attributes that made the 4.0L great was its relentless durability. Regarded as one of the most reliable engines ever built, it will routinely last beyond 200,000 miles with proper maintenance. The engine first appeared in the 1987 XJ Cherokee and remained a staple in the Jeep lineup until 2006, when it was replaced by a new 3.8 liter V6.

Like any piece of machinery with a lifespan of almost two decades, Jeep's 4.0 liter straight six engine had good and bad years, separated primarily by an upgrade to the multi-port fuel injection system and troublesome cylinder heads.

The 1987-90 Renix system was problematic

Troubled years ran from its debut in 1987 through the 1990 model year, when the Jeep 4.0 was equipped with an engine management and fuel injection system made by Renix, a partnership between Renault and Bendix. Although previously used on the 2.5L — another highly reliable old Jeep engine — the system was more complex than the Mopar computer and FI system that appeared in 1991. The Renix system had a troublesome knock sensor, and the computer managed engine timing automatically, although this could be tweaked slightly by adjusting the mount points of the crankshaft position sensor. Furthermore, the 1987 Renix 4.0 was the least powerful version of this engine, producing 173 horsepower and 220 pound-feet of torque. The next year, higher-capacity fuel injectors boosted output marginally but did nothing to expel the electronic gremlins.

The Renix system was unable to store engine fault codes, making troubleshooting difficult. Chrysler abandoned it beginning with 1991 models, replacing it with an in-house engine management and fuel injection system. The intake and exhaust manifolds were also redesigned, and a larger throttle body and higher capacity fuel injectors went atop the intake.

1991-1993 fuel injectors were prone to leaks

Although Chrysler upgraded the engine management system in 1991, adding a computer that could store fault codes, the injectors used in the next few years of the 4.0 were prone to leaks, even if replacements were relatively cheap. All the changes boosted the 4.0's output to as much as 190 horsepower and 232 pound-feet of torque in the XJ Cherokee. The Wrangler's version was slightly less powerful due to variations in the air cleaners and exhaust manifolds between the two models. The injector design was changed in 1993, with engines made from this point on far more desirable for consumers.

The block was strengthened for the 1995 model year, lending the 4.0 additional strength. That was the final year for the YJ Wrangler, although the 4.0 lived under the hoods of Cherokee, Comanche, Wagoneer, and Grand Cherokee models. The engine would remain in use until 2006 but peaked in desirability a few years before the end of its run.

The 1995-99 were the peak years

The 4.0L engines made in the years from 1995 through 1999 are the best of the bunch. In 2000, a distributor-less coil-on-plug ignition system was introduced, which was more expensive to replace on a routine basis than the original distributor and coil components. Cherokee and Grand Cherokee models from the last few years of the 20th Century will typically run well beyond 100,000 miles.

Randy Lorentzen of Motor Trend paid tribute to the late '90s 4.0 in his review of the 1997 Cherokee, writing, "This long-lived OHV powerplant has a reputation for getting people where they need to go, whether it be through a blizzard or ascending a craggy mountainside. Even saddled with the four-speed automatic transmission, this unassuming motivator propels the 3153-pound Cherokee 0-60 mph in a quick 8.2 seconds after several thousand break-in miles."

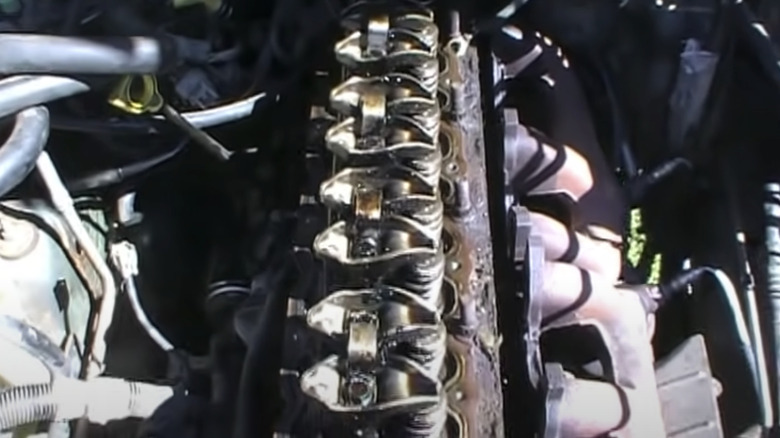

Early 2001 heads are prone to cracking

In 2001, a crack-prone cylinder head was installed. They have the casting number 0331, which can be found on the driver's side of the block where the edge of the valve cover meets the cylinder head. If you find the telltale 0331 stamped there, don't panic and run away from a prospective purchase — the heads on that engine can be replaced aftermarket. If the seller will allow it, remove the valve cover and look for a crack between cylinders three and four. You can also remove the oil filler cap and peek inside with a flashlight, but this won't give you as clear of a look.

The head was strengthened mid-2001, and upgraded heads have TUPY stamped near where the old ones were prone to cracking. The 4.0L engines from 2001 to 2006 made marginally more torque than the late '90s versions, but horsepower remained unchanged at 190. The problematic cylinder heads in the later engines make the pre-2001 versions more desirable, and output can be improved by installing aftermarket exhaust headers in place of the stock manifold. This is vital if you plan to go off-road, as powerful torque on a compact chassis is part of what makes Jeeps incredible climbers.