How To Select The Right Milwaukee Sawzall Blades For Your Next Project

We may receive a commission on purchases made from links.

Taking on DIY home improvement projects is really just a perpetual game of determining if you have the right tools for the job. You may have a screwdriver, but is it the right head? And you have a trusty ratchet set, but do you have the right socket size? Things get even more complicated when you need to saw through something. Is your Sawzall blade the right one for the project ahead?

While you can trust Milwaukee to have a bounty of Sawzall blades, you can't just buy any blade for your specific project. If you look really closely at the different blades available at Milwaukee, you'll notice little variations in tooth length, the blade's profile, and the number of teeth per inch (TPI).

If you're antsy to start your next DIY project but need a little help navigating the many different types of blades for your Milwaukee Sawzall, we're here to help. Below is a quick guide breaking down the differences in each blade type to help you best select the one that will get the job done.

What material are you cutting through?

When shopping for a new Sawzall blade, the most important question you have to answer is what material you need to saw through. There are different types of blades with different features designed to cut through metal, PVC, wood, and more.

With Milwaukee tools, there are three categories of Sawzall blades, and each category has three different blades available, which we'll discuss shortly. Compared to others, wood-cutting blades tend to have fewer TPI, allowing you to saw through quickly, albeit not quite as cleanly. This may leave a rougher surface area, but depending on the needs of the project, wood can be sanded easily to a smooth finish.

Metal saws will have more teeth per inch and may be made from a stronger, thicker metal. Milwaukee Sawzall blades range from seven to eight TPI and are either carbide or nitrous carbide to saw through anything from steel to cast iron.

If your project involves cutting through wood and metal, there's also a multi-material category of Sawzall blade. Multi-material blades combine the best of both worlds with a mid-range TPI, carbine teeth, and an average profile height and length for controlled stability.

Along with TPI, you also need to look at the length of the blade. Longer blades offer a deeper cut but can also be wobblier while cutting. A long, wide blade will offer a more balanced experience, though you'll want to consider something short for plunge-cutting, like when working with softer materials.

Milwaukee Sawzall blades for cutting through wood

Whether you're cutting through branches or sawing through 2x4 planks, Milwaukee has a trio of Sawzall blades designed specifically for wood. Since an outdoor project may involve cutting close to the ground, wood-cutting Sawzall blades tend to feature a larger gullet or the space in front of the tooth. Large gullets prevent debris from building up. In this case, dirt and pebbles.

The lower profile of Milwaukee's three TPI Ax with Carbide Teeth for Clean Wood/Pruning makes it easier to cut through roots. There is also The Ax Bi-Metal Sawzall Blade, a higher-profile wood-cutting blade. These taller blades add accuracy to your cut, making them ideal for DIY projects that require precision.

Milwaukee blades not made for pruning may also come with a Nail Guard. The Ax with Carbide Teeth for Nail-Embedded Wood is a heavy-duty, fang-tipped alternative ideal for sawing through installed or previously used wood that may still have nails.

Milwaukee Sawzall blades for metal cutting

The type of metal you're cutting through will determine which Milwaukee Sawzall blade you opt for. While they're all fairly higher in profile for increased stability while cutting, there are variations in TPI and material.

For example, the Torch Bi-Metal Sawzall Blade has the least amount of teeth at seven TPI and is made from a durable carbide. While a capable option for most metal cutting, the bi-metal Sawzall blade is a little less efficient with thicker metals than the Torch with Carbide Teeth for thick a metal blade uses a stronger tooth to maximize performance while sawing through stainless steel, rebar, black pipe, and other strong metals.

An upgrade from the carbide teeth is the Torch with Nitrus Carbide. While the carbide teeth can do a number on most metals, the nitrous carbide takes it a step further by adding cast iron to its applications.

Multi-material Milwaukee Sawzall blades

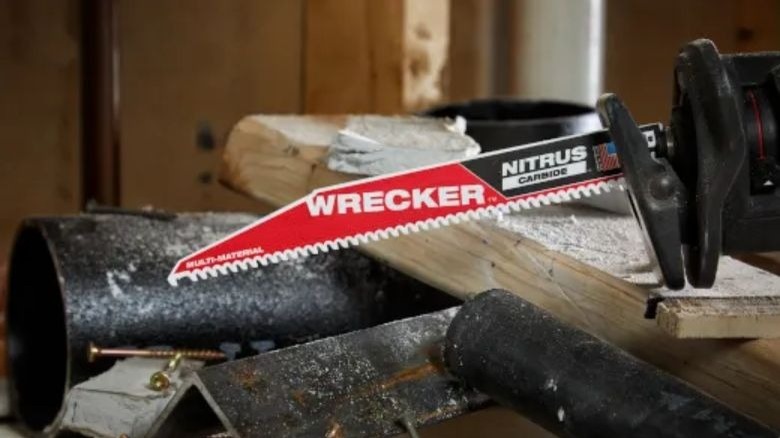

The Wrecker is Milwaukee's Sawzall blade, designed to cut through everything from wood to thicker, more resistant materials. While it's designed similarly to its metal counterpart, the profile height varies.

For example, the Wrecker Bi-Metal Sawzall looks similar to the Torch Bi-Metal Sawzall, but it has a more dynamic profile that ends in a point, like a wood Sawzall blade. The Wrecker with Carbide Teeth has a similar design to the Torch's carbide option, though it has two fewer TPI and a more defined pointed edge.

Additionally, the Wrecker's Nitrus Carbine option makes it a durable multi-material option, though its six TPI makes it a great option for wood and other materials that don't require such a clean cut. Being a mid-range option means you can enjoy stability while cutting through less durable materials like wood while still getting the strong, sturdy cut needed to get through thicker, stronger metals.