Fuel Injection Vs Carburetor: The Biggest Pros And Cons

Anyone who has gone to school to learn how to repair engines of all types, such as myself, will have learned the fundamentals of how they work. It's crucial for troubleshooting and diagnosing engine failure. One of the most crucial fundamentals to understand is fuel delivery. With well over a century of development, many ideas have been introduced to make this process work, but, ultimately, most engines in existence use one of two options: a carburetor or fuel injection.

The basic function of both carburetors and fuel injection is to blend fuel with air in such a way that it can burn efficiently once introduced into the combustion chamber of an internal combustion engine — that includes all gasoline and diesel engines, plus a few others burning alternative fuels such as propane or natural gas. The primary goal of either system is to deliver air and fuel in a stoichiometric ratio, which is the optimum balance of fuel and air for complete combustion to occur. The secondary goal is to deliver the fuel as efficiently as possible. In modern times, a tertiary goal is to do all this with the fewest possible harmful emissions resulting from combustion. Fuel injection and carburetors go about fuel delivery using markedly different processes, and these are the biggest pros and cons of each system.

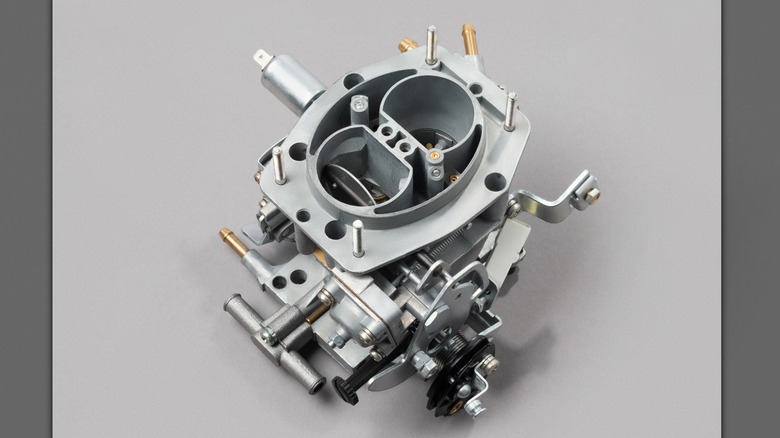

What is a carburetor?

The oldest device for fuel delivery is the carburetor. Very early engines ran on gas (not gasoline), requiring rudimentary metering valves. However, in 1885 Karl Benz, founder of the Mercedes-Benz auto manufacturer, patented the first carburetor for an engine to run on liquid fuel to use in his Patent Motorwagen, the first car ever invented. The carburetor then spread to be the primary method of fuel delivery for about a century.

The carburetor is a mechanical device that manipulates a few fundamentals of physics to turn a liquid fuel into a vapor mixed with air that can readily burn when under pressure and introduced to a spark. Basic models, like the ones that go on lawnmowers, are made of only a few parts, but those on cars can be extraordinarily complex.

Carburetors store fuel in a small tank, to be drawn into an engine from air passing through a small cylinder. This cylinder, or barrel, narrows and then widens, creating what is called a venturi. Air passing through a venturi speeds up, creating an area of low pressure. A small hole, or jet, is placed in the low-pressure area and the resulting vacuum sucks fuel into the air stream. On the bottom of the barrel is a throttle plate controlling the amount of air that can flow through the carburetor while a choke plate at the top decreases the air available for extra fuel on cold starts. There are huge variations to exactly how this happens, but all carburetors work on these basic principles.

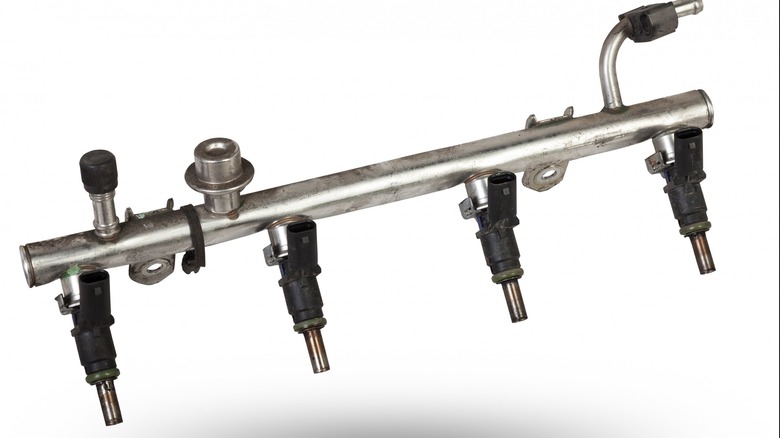

What is fuel injection?

First built in 1906, the Antoinette 8V aviation engine was the first gasoline engine with a primitive forerunner of fuel injection. The technology was further refined but remained confined to aviation until the 1940s. Fuel injection systems first appeared on race cars in the '40s, but it would not be until the '50s that production automobiles received fuel injection, with the release of the Mercedes-Benz "Gullwing" 300SL.

Fuel injection systems rely on pressurized fuel delivered by a high-pressure pump in the fuel tank to valves called injectors on the engine. The fuel is delivered into the engine directly from the injector, which has several pinholes to atomize the fuel as it enters the airstream into the engine. A throttle plate controls airflow while sensor inputs control fuel flow and engine sensors control injector pulses' timing.

Early systems relied on various pumps, diaphragms, and other mechanical sensors to operate. They were complicated and expensive, and so used mostly in luxury and sports cars. Eventually, that was replaced by electronic fuel injection, which used multiple electronic sensors to monitor engine conditions to be calculated by an electronic control unit that would activate the injectors, and deliver the precise amount of fuel at the right time.

Early throttle body systems had fuel injectors instead a carburetor but were replaced by more efficient port injection systems with individual injectors on the intake port of each cylinder, the most common system today. The newest system, which is growing in popularity, is called direct fuel injection, and its fuel injectors spray fuel directly inside the combustion chamber.

Technological improvements of carburetors

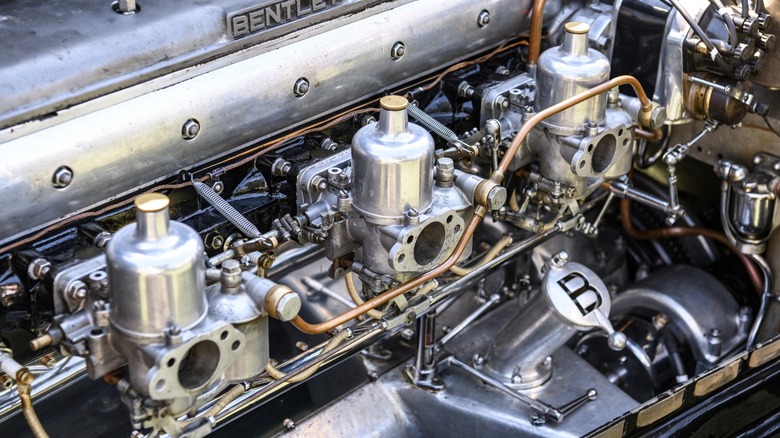

Both of these fuel delivery systems operate on the same principles but have seen drastic technological improvements over time. While builders of the earliest carburetors were likely happy that they worked at all, they found ways to make improvements immediately. Early automobiles used updraft carburetors, which drew air in from down low and up into the engine, preventing engine flooding by being mounted low at the side of the engine. They were simple and easy to make. By the 1930s, downdraft and sidedraft carburetors mounted on top of the engine dominated, offering better air filtration and more precise fuel delivery. Continued refinement led to two and then four-barrel configurations as well as multiple-carburetor setups, such as the Mopar Six-Pack on some rarer Chrysler muscle cars, and the iconic Lamborghini Miura V12, which featured six two-barrel carburetors.

Automatic chokes were invented in the '30s but did not become widely used until sometime in the '60s or '70s, and carburetors matured into being relatively complex but robust engine components offering good efficiency and reliability. However, emissions regulations of the '70s saw manufacturers trying to clean them up. Before the widespread adoption of fuel injection, most manufacturers attempted to clean up emissions with computers controlling their carburetors with mostly unfavorable results. Chrysler's Lean-Burn system was notoriously unreliable, and Hondas of the era came with miles of spaghetti-like vacuum hoses. These complicated and unreliable systems delivered only marginal improvements in emissions outputs, and plagued car owners for too many years.

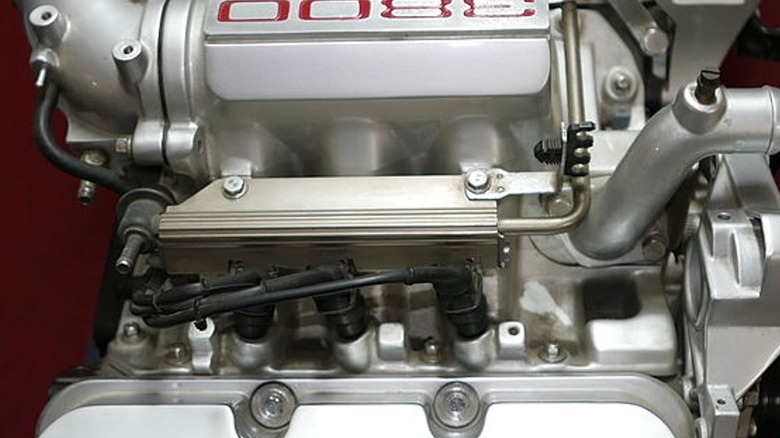

Technological improvements of fuel injection

The evolution of fuel injection charted a course full of innovation and sophisticated solutions. Mercedes-Benz equipped its 1954 SL300 cars with a fuel injection system that its race cars had previously developed from the infamous Messerschmitt Bf 109 WWII fighter plane. A few years later, Chevrolet Corvettes were offered with a Rochester Ramjet mechanical fuel injection system. Although this option cost around $500 in the late '50s, it delivered a benchmark one horsepower per cubic inch and measured its fuel requirements from vacuum inputs, delivering fuel through a mechanical distributor and eight fuel lines.

In 1957, Chrysler offered the Bendix Electrojector system as an option on some models. This was the first electronic fuel injection system, although it was not digital. It used a controller made with analog circuitry and, in early iterations, vacuum tubes. All cars sold with this option were recalled, as the primitive electronics failed miserably in real-world conditions. VW improved on this with Bosch D-Jetronic fuel injection, which proved to be reliable, thanks to its solid-state circuitry. More refinement came to fuel injection systems as Cadillac introduced electronic fuel injection on the 1976 Seville. And in 1980, Bosh introduced Motronic, the first system controlled by integrated circuits.

For the last 40 years, fuel injection systems have become more advanced, precise, and efficient. With even higher-pressure secondary fuel pumps, direct injection sends highly atomized fuel directly into the cylinder with precision, to further increase efficiency and power output.

Benefits of a carburetor

At one time, there were no inherent benefits to a carburetor because there was no other technology to replace it. That time passed long ago but carburetors still exist today and can be found attached to millions of engines. The reasons why are varied and all of them are for practical considerations.

Perhaps the biggest reason a carburetor would be chosen today is due to its overall cost being less than that of a fuel injection system. They are simple, purely mechanical, and require no expensive computerized or electronic components. The design and assembly represent the bulk of the cost, and no software needs to be written for them. They all use a handful of basically the same parts and are relatively easy to assemble. This also makes them capable of lasting for many years. As long as the gaskets, seals, and other assorted rubber components hold up, a carburetor will work as long as it is properly tuned.

The primary reason carburetors are not as widespread as they once were is efficiency. As much as engineers have worked to make them efficient, they will always pale in comparison to fuel injection.

[Featured image by Reforma.imufomot via Wikimedia Commons | Cropped and scaled | CC BY-SA 3.0]

Benefits of fuel injection

The primary reason for choosing fuel injection is clear: efficiency. A carburetor can not come close to metering the exact amount of fuel needed at exactly the right time in the way modern electronic fuel injection can. Mechanical fuel injection can also offer greater efficiency than a carburetor, but electronic systems are by far the most efficient.

The makeup of fuel injection systems at their core is relatively simple. They all use some kind of injector, a throttle, a fuel pump, and an array of sensors. However, the software and engineering of modern fuel injection systems are highly complex, contributing to the high cost of development. The components in the early days had to be designed and custom-built, but now the technology has been around long enough that individual parts are more affordable. Furthermore, with decades of production, fuel injection systems have proven to be incredibly robust and easy to diagnose with the right scan tool and a little bit of training.

For drivers, this all means you enjoy better fuel mileage, more power, and increased reliability. Electronic fuel injection requires no adjustments or tune-ups and eliminates all of the problems of cold starting and cold-weather performance.

[Featured image by OSX via Wikimedia Commons | Cropped and scaled | CC BY-SA 3.0]

Applications of fuel injection and carburetors

Both carburetors and fuel injection remain relevant today. Unless you drive a classic, your car is fuel-injected — the last car sold in the United States with a carburetor was the 1990 Subaru Justy, although the Isuzu Pickup did not receive fuel injection until after the 1994 model year. While the 1969 Munch Mammoth motorcycle became the first fuel-injected motorcycle in production, the tech did not become widespread until more recently.

Today carburetors are largely relegated to small-engine use. Lawnmowers, chainsaws, and scooters represent the majority of modern machinery equipped with them. In the world of aviation, most new aircraft use fuel injection. However, the life of a given aircraft can be much longer than a car. The average age of a general aviation aircraft is 50 years old, and many that still fly use carburetors. This means the aviation carburetor business is as busy as ever. Carburetors also continue to be used in auto racing and remain important to classic car ownership and restoration.

Despite the dominant use of carburetors for small engines, the tide is turning. As far back as 2003, Honda developed its first fuel injection system for a 50cc 4-stroke engine, and the major chainsaw brand Stihl currently offers a fuel-injected chainsaw. Carburetor usage continues to decline, but it is not dead just yet.

Which one is better?

For the vast majority of modern applications, fuel injection will provide more efficiency with reliable operation. It is more expensive to produce and install, but the technology has matured and proliferated enough to bring the prices down significantly from what it was during its infancy. In some limited applications, a carburetor may be the preferred choice, usually due to cost and simplicity. In remote regions with limited resources, where modern computers and testing equipment are unavailable, having a carburetor could be beneficial as repairs and adjustments can be done mostly with basic hand tools.

Fuel injection is the rational choice for all applications in which its cost does not climb to an untenable level. In small engine applications, the use of fuel injection is growing, particularly among equipment at the higher end and targeted toward professional use in particular. However, the small engine carburetor market remains huge, involving many global manufacturers who still see growth potential on the horizon. Nonetheless, battery power continues to grow in applications traditionally using small engines. Regulations coupled with consumer demand could see more small engines swapped for batteries in the years ahead.

The future of fuel delivery systems

Since carburetors are a partially obsolete technology, the development of future products is limited. Most upcoming developments regarding carburetors will likely revolve around classic cars and racing. Edelbrock and Holley, two longtime carburetor manufacturers, continue to develop their products, with Edelbrock releasing a new and improved model in 2019, the Edelbrock AVS2. Furthermore, PRW recently announced the production of brand-new Rochester Quadrajet carburetors, the model GM installed on millions of V8 engines for about 30 years.

However, the development and innovation of fuel injection are continuing. Widespread use of gasoline direct injection is one of the more exciting developments in recent years, but more can be done. Engineers are also working on adapting direct injection for use with liquid propane engines and for the burgeoning technology of hydrogen-powered. Ducted fuel injection, which is under development for diesel engines, uses small tubes to spray the fuel to different areas within the combustion chamber, leading to less soot and greater efficiency. Direct injection is under development for Honda's long-running Africa Twin motorcycle while Kawasaki is taking it a step further by combining port and direct injection for future models.

Even with the incredible fuel delivery technology already in production today, rest assured more clever and innovative designs promising more power and efficiency will be coming as long as internal combustion engines stick around.

[Featured image by Craigblock at English Wikipedia via Wikimedia Commons | Cropped and scaled | CC BY-SA 3.0]