The Inline-6 Engine Is Making A Comeback: Here's Why

There is a trend happening in the automotive industry lately — engines are losing cylinders. Partly due to downsizing and electrification, we are witnessing the demise of powertrains with more than four cylinders. The V12 is almost completely eradicated, V10-powered cars on sale today can be counted using two fingers, and the once ubiquitous V8 is being replaced by smaller engines, even in the United States.

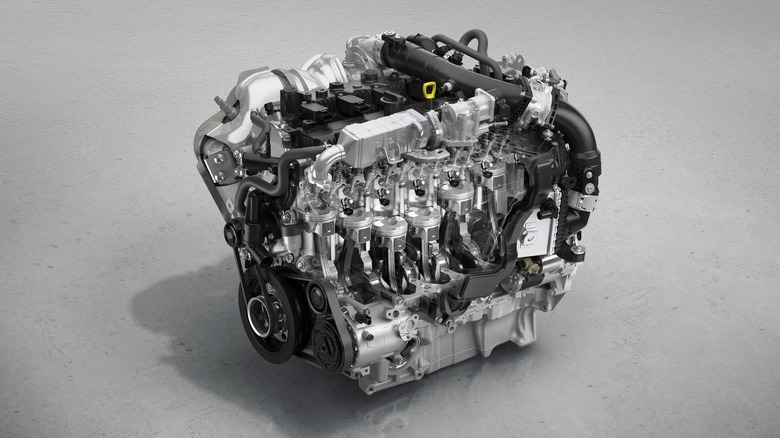

But the V8, at least, might get a worthy successor. Sure, this won't go well with most enthusiasts, but in an era of electrification, the inline-6 will keep the old-school muscle alive, like in the 2025 Dodge Charger Sixpack. In fact, inline-6 engines are coming back into fashion after being almost completely replaced by V6s. It seems counterintuitive, but for modern vehicles, straight-six powertrains simply make more sense than any V-configuration unit. Not to mention, they are miles better than those unrefined four-cylinder units.

So, is the inline-6 engine making a comeback? Brace yourselves, this cylinder-deleting story might make you a believer in the straight-six engine once again. Future generations may look at it the same way we look at V8s — here's why.

Cheaper to produce than a V6

Although making better cars is definitely a driving force for many automakers, making more money is very important too. Despite all their disadvantages, inline-6 engines open up profit margins.

These engines have one cylinder head and one exhaust manifold, compared to two in V6 motors. Moreover, there are fewer camshafts in an inline-6 engine and a shorter timing belt. In addition, the engine block has a simpler construction, which streamlines manufacturing. Due to the fewer internal parts, it is also easier to lubricate inline-6 than V6 engines. And because they are inherently balanced, straight-six powertrains don't require balancing shafts, cutting down costs and complexity.

Finally, inline-6 engines are simpler to make, which means manufacturing them at scale is simpler. It requires fewer tools and takes less time. While automakers have found ways to optimize V6 manufacturing, inline-6 engines still have the upper hand in that department.

Scalability

When V8 engines were ubiquitous in higher-end luxury cars, automakers could scale them down to V6 engines by chopping off two cylinders. Sure, it is slightly more complex than that, but many V6 and V8 engines of the past shared the same pistons, connecting rods, piston rings, and bearings. This scalable approach allowed them to cut manufacturing and development costs significantly while providing customers with more offerings.

However, V6 engines are on the chopping block today due to engine downsizing, in favor of turbocharged four-cylinder units wildly different in design from V8s. However, there is an engine that is similar in construction to an inline-4 — the inline-6. These engines can share most internal parts and feature a similar block and head design. Not to mention, manufacturers could even use the same production line for their inline-4 and inline-6 engines.

In fact, inline-6 engines are even more scalable than V6s and V8s, because in V configurations, changing the angle between the cylinder banks is often necessary. Notably, the best angle for a V6 engine is 60 degrees, while for a V8 it is 90 degrees, which hurts scalability. In inline-4 and inline-6 engines, all cylinders are arranged in a line, so part sharing is much easier.

BMW and Mercedes-Benz both use this modular approach in their 2.0-liter inline-4 and 3.0-liter inline-6 engines. Each of those units shares the same 500cc cylinder capacity, along with similar pistons and connecting rods. So, in a sense, the inline-4/inline-6 combo is replacing the V6/V8 combo in modern luxury cars.

Smoother operation than a V8

American cross-plane V8 aficionados will tell you that the reason they love these engines so much is because they are smooth and refined. That is true if you compare them to V6s or small four-cylinder engines because the pistons from the two banks (in a 90-degree configuration) cancel each other's movements. Even so, in 90-degree V8, there is still oscillation, and a counterweight is required at each cylinder to minimize vibrations. Those counterweights make the whole engine less responsive.

If smoothness is the reason why you like V8s, then you will love inline-6 engines because they are even smoother. Straight-six engines are longitudinally balanced and don't require balancing shafts because there is always a pair of cylinders doing the same movement and another pair doing the opposite movement. Moreover, the pistons in inline-6 engines cancel each other's vertical and transverse forces. With all of those forces compensating each other, you have a completely balanced engine with almost no vibration.

The inline-6 engine isn't the only configuration with perfect balance. Boxer engines, regardless of the cylinder count, are also inherently balanced, and the same is true for V12 engines. Still, in today's world, where V8 powertrains are a dying breed, straight-six engines are the next best thing for luxury cars. They are smaller and more accessible, yet still buttery smooth.

More reliable than V6 and V8 engines

Reliability in cars is a complex matter. Most automakers invest in making their vehicles more reliable, but not all of them are successful. It requires meticulous engineering and deliberate design choices to reduce the chances of breakdowns. Still, if you start from scratch, it would be easier to make a reliable inline-6 engine than a V6 or V8 one.

The simple design with fewer moving parts that makes straight-six powertrains more cost-effective also aids in durability. That is true even for simple items. For instance, V6 and V8 engines have more than double the number of gaskets and seals, leading to more frequent oil leakages. Having two engine heads, each with two camshafts, also increases the chances of something breaking down.

Moreover, the natural balance of inline-6 engines leads to smoother operation, meaning less wear on engine components, particularly bearings. Cooling and lubricating a straight-six uniformly is also easier, as the fluids have less path to travel to reach internal components.

There is a reason why older inline-6 engines, like Toyota's very special 2JZ-GTE and Nissan's legendary RB26DETT are the darlings of the tuning scene. They are strong, durable, and reliable. BMW's B58 is another prime example — it might be the Bavarian company's most reliable engine ever. And let's not forget the 5.9-liter and 6.7-liter Cummins inline-6 diesel engines, both considered tough and durable.

Inline-6 engines are generally easier to work on

Open the bonnet of a car with a V6 or V8 engine, and the complexity might make your head spin. V-configuration engines are usually more tightly packed under the hood, with not much space left for you to work on. Even a simple spark plug change could be a nightmare on most V6 and V8 engines.

Inline-6 engines are the complete opposite —the spark plugs and ignition coils sit on the same side, near the top of the engine. Heavy repairs are also much easier on an inline-6 engine. For instance, the exhaust and intake manifolds are clearly separated and easy to reach. Opening the cylinder head cover is also straightforward because the engine sits vertically, and the valvetrain components are easier to reach. Not to mention, V6 and V8 engines have two-cylinder heads and need to be removed for most repairs, so double the job.

Other components, like the timing chain, water pump, A/C pump, thermostats, and oil filters, are all easier to reach on inline-6 engines. Additionally, less disassembly is required to reach each of those parts, which can significantly speed up the process. Overall, straight-six engines cut maintenance and repair times, allowing dealers to serve more customers faster.

More efficient and cleaner than a V8

Although the motto "there is no replacement for displacement" has truth to it, engine downsizing still brings benefits in fuel consumption and emissions. In most driving situations, a turbocharged inline-6 that produces roughly the same horsepower as a naturally aspirated V8 will be more efficient. And it makes sense.

For starters, inline-6 engines have fewer pistons to move, meaning the combustion has less inertia to overcome. For the same reason, there is less friction inside straight-six engines than V8s. Thus, inline-6 engines can convert more of the combustion energy to motion rather than heat. These gains aren't huge, but they are real.

Manufacturers today use all sorts of trickery, like injecting the fuel at a precise moment to maximize combustion, accompanied by a forced induction for more power. Meanwhile, smaller and lighter variable-geometry turbochargers transform engine performance by spinning up faster, making turbo lag a thing of the past. With all these small improvements, contemporary inline-6 engines can offer similar acceleration and feel to V8 engines while using less gas. A win-win!

Tailpipe emissions are also reduced in inline-6 engines, and not just because of the lower fuel consumption. Namely, because the exhaust pipes are connected to one cylinder bank, manufacturers can place the catalytic converter closer to the engine, allowing it to reach its operating temperature more quickly.

Modern inline-6 engines are much more compact

Automakers are increasingly using electricity in modern cars — not only for better fuel economy but also for packaging concerns. For instance, an integrated starter generator/alternator (ISG), powered by a 48-volt electric system, allows engineers to completely electrify auxiliary engine parts, like the water and A/C pumps.

Therefore, ISGs eliminate the accessory belt, cutting a few inches from the overall length. It might not be much, but it was enough for Mercedes-Benz to replace its aging M276 V6 engine with the M256 straight-six. ISGs have other advantages as well. Namely, they are torquey enough to fill up the gap before the turbocharger spools up, significantly reducing turbo lag. In the M256, the ISG produces 20 hp and 162 lb-ft of torque!

Furthermore, manufacturers are decreasing the size of the latest inline-6 engines by reducing the bore of the cylinder and substituting it with a longer stroke. For example, Mercedes' 3.0-liter M256 motor has an 83-mm bore and 92.4-mm stroke engine, which cuts the distance between the bore centers by 16 mm (0.63 inches). Of course, that is still not enough for an inline-6 to be as small as a V6, but it is much better than before.

Well-suited to turbocharging

V-configuration engines are packaging champions when it comes to forced induction, as the turbochargers can sit between the cylinder banks. But that's about where the advantages of these engines end, regardless of the differences between supercharged and turbocharged designs. The pipework for the intake and exhaust in V6 and V8 engines is much more complex, and it becomes increasingly so once you factor in forced induction.

Meanwhile, inline-6 engines have simple intake and exhaust plumbing. Thus, designing and manufacturing these parts is more cost-effective, and it is also easier to combine them with a turbocharger. Besides, inline-6 engines leave a lot of space on the side inside the engine bay, allowing for some very big turbochargers or superchargers. Due to the simple pipework, in general terms, there should also be slightly less turbo lag in inline-6 engines.

Even if you disregard the simplicity of a turbocharged inline-6 engine, it is still a better fit for turbocharging thanks to its inherently balanced nature.

Unique selling proposition

Most car lovers will agree that turbocharged inline-4 engines are the worst thing that has happened to the automotive scene in the past decade. For instance, the latest Mercedes-AMG C63 features a four-cylinder plug-in hybrid instead of a twin-turbo V8. Sure, the S version has 671 hp on tap, making it much faster than the previous model (503 hp). However, the general consensus is that the latest C63 lacks the personality of its forebearers, though it's too early to tell whether this will hurt sales.

Meanwhile, BMW is stealing the spotlight with its M3 and M4 turbocharged inline-6 gems. They sound better and feel much more refined. And in an era when EVs are annihilating internal combustion engine cars in acceleration times, enthusiasts are starting to value experience more than speed. Simply put, inline-6s will always feel and sound better than inline-4s, power be damned.

Look at what Mazda is doing with its CX-90. The Japanese automaker has never offered inline-6 engines (only V6s) but has now introduced one, despite the recent push for EVs. Mazda wants to become a premium brand that competes with the German trio of Audi, BMW, and Mercedes-Benz, and having an inline-6 offering (or at least a V6 one) is virtually essential in that segment. Let's just hope that other automakers follow suit.