Wilson's Airless Basketball: Full Of Hidden Tech With A Hefty Price Tag

With technology creeping into every facet of our lives, innovations in all industries have become much more exciting. The advent of 3D printing technologies, specifically, has given rise to unprecedented levels of customization in product design, allowing companies to create not just complex architecture but ones that were simply unachievable through traditional manufacturing processes. The Airless Gen1 Basketball by Wilson is one such recent breakthrough that pushes the envelope in additive manufacturing and in price.

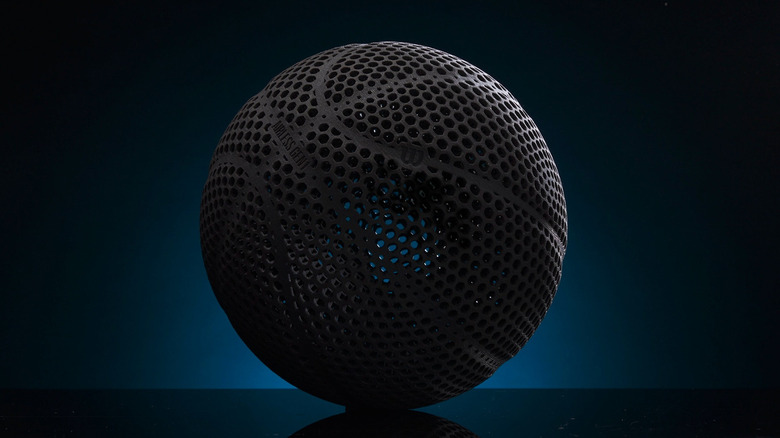

First revealed during AT&T's Slam Dunk Contest in February of 2023, Wilson claimed they had "reinvented" the basketball — showcasing to the crowd a 3D printed jet black marvel that bounced just like a regular air-filled basketball. A span of 12 months has been successful for the sports equipment manufacturer in not only bringing this prototype to the commercial market but also in demonstrating the advantages that an airless basketball brings. But does the impressive engineering and the product's unique proposition justify the exorbitant $2,500 price tag? More importantly, how does it bounce?

Beyond inflation: The science behind the airless basketball

Wilson's Airless Gen1 Basketball features an intricate polymer lattice structure crafted from a proprietary elastomeric material that is flexible, durable, and, more importantly, bouncy. In layman's terms, a 3D lattice structure works on the principle of connecting repeating patterns into a three-dimensional shape, offering tons of flexibility in the types of products one can craft. The right combination of geometry, stiffness, stability, and impact absorption, paired with the Airless Gen 1 Basketball's perforated design, makes it bounce so well.

Produced in collaboration with EOS, the basketball is made using lasers that bind layers of a polymer powder into the 3D design that's been fed into the printer. The ball is then sealed and dyed according to specification. EOS, the 3D printing company that usually produces for the aerospace, medical, and automotive industries, claimed that additive manufacturing using a 3D printer was the only way the conceptualized airless basketball could be brought to life.

The finished products would then be sent to the NBA's task facility in Ohio, where all parameters of the ball would be rigorously tested. The result? A basketball that doesn't come with any of the drawbacks of deflation or pressure change due to temperature — and one that nearly fits all NBA regulations in size, weight, and bounce.

The price you must pay for innovation

Improvements from the original prototype include an updated eight-panel design and a seam going across the ribs of the ball that resembles a regular basketball. The Airless Gen1 is also available in two new colors, brown and white. While the Airless Gen1 Basketball fixes the most annoying issue of a traditional ball, only time will tell how well the structure holds against the ground. Something we are also concerned about is the hundreds of hexagonal holes possibly getting clogged up by dust and tiny stones — that is, if anyone who's bought this is actually going to be using it to play outdoors.

Despite the $2,500 asking price for this engineering feat, the limited edition drop of 200 airless basketballs was quickly sold out, with no information of a subsequent stock. Perhaps the novelty of owning one-of-a-kind sports equipment aided in the quick depletion of available units. Every purchase comes with a pelican case; a fancy mirror display stand to showcase your luxurious purchase, a customizable genuine NBA leather insert, and a luggage tag.

If you like to 3D print your own creative designs, here are five tips essential for beginners and experts.