What Is A Turbo Blowoff Valve, And How Does It Work?

One of the turbo engine's most iconic sounds is called the turbo flutter. That "stu-tu-tu-tu" sound the Nissan Skyline GTR R34 makes as the throttle closes is the sound of compressed air escaping past the compressor fan blades. At the core of it, this phenomenon sometimes follows a compressor surge, where there's too much turbo-compressed air, but the engine can't use it. A blowoff (or recirculating) valve is designed to solve this problem and release (or reuse) the air.

While turbo flutter may sound cool to you, it could put unnecessary strain on the turbo system, and it will cause the components to wear faster. Unless you're in the expensive habit of buying replacement turbochargers more often than you should, a blowoff valve is the best way to reduce wear and save costs. Plus, the blowoff valve makes its own cool wooshing or hissing sound.

However, turbo flutter doesn't always indicate a compressor surge. The damaging surge happens only when the returning compressed air stalls the fan wheel, killing its momentum and causing more turbo lag. The famous turbo flutter is only the sound of the blades "cutting" through the escaping air. Let's start with the basics: You'll need to understand how a turbocharger works to appreciate the blowoff valve.

How a turbocharger works, and why it's affected by compressor surge

As you may know, combustion engines work by injecting an air-fuel mixture into the combustion chambers for ignition. More powerful combustion means a more powerful engine. However, these combustions need oxygen; the more oxygen, the more power an engine can generate.

A four-stroke engine sucks in air and fuel through their respective valves, compresses the mixture, detonates it, and then blows off the exhaust fumes through exhaust valves into the exhaust manifold. A turbocharger uses the air pressure from the exhaust gases to spin a turbine, which in turn drives a compressor that sucks in air, compresses it, and sends more oxygen to the engine. A turbocharged engine receives more oxygen than its regular counterparts, producing more powerful combustion.

Because a turbocharger needs the exhaust to work, you might need to wait before the extra power from the turbo kicks in. This gap in power is called turbo lag, and it's one argument against turbos in the turbocharger vs supercharger debate. For air to get to the engine in the first place, the throttle valve must be open. You control the throttle valve with the accelerator pedal. The lower you push it, the wider the throttle valve opens. When you take your foot off the pedal, to switch gears for instance, the valve closes. But your turbocharger may still very well be pumping the same amount of oxygen to the engine.

This unneeded compressed air from your turbo will meet a closed throttle valve, and since the air has nowhere else to go, it will return back to the compression chamber and cause a compressor surge.

How does a blowoff valve help compressor surge?

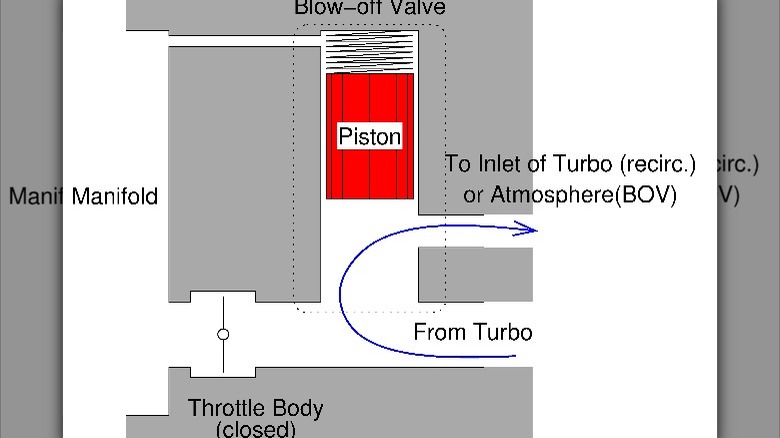

A blowoff valve is typically located after the intercooler (a cooler for cooling compressed turbo air) along the turbo outlet's piping. It serves as an ideal escape route for the compressed air, so the bulk of it doesn't have to return to the compression chamber. The blowoff valve can detect when there's too much pressure, and it will open its outlet so that the air can escape.

It typically works using a spring mechanism and a piston. By default, the piston clamps down and stops air from getting into the blowoff valve and escaping. Of course, the spring isn't powerful enough to hold the piston down with all that high-pressure air. Instead, there's another pipe on the top half of the blowoff valve connected to the engine's intake manifold — this allows an equal amount of high-pressure air to support the piston from the top and stop air from getting in.

When the throttle valve closes completely, there's now a vacuum in the engine's intake manifold, and the pressure from the turbo piping becomes strong enough to push the piston and the spring, allowing the air to get into the blowoff valve and escape. Once all the air has escaped, the blowoff valve's spring will push the piston back to its clamping position. Some blowoff valves recirculate the air back into the turbo system instead of wasting it. Many factory-fitted blowoff valves use that instead for better efficiency.

[Featured image by Akyeren~commonswiki via Wikimedia Commons | Cropped and scaled | Public Domain]