The Pratt & Whitney Engine That Changed Air Travel Forever

Amelia Earhart's famous aircraft, the Lockheed Electra 10E Special, was her choice for the tragic round-the-world journey that ended with her disappearance. It was selected in part because Electra was powered by a very special piece of equipment: the Wasp engine.

This mechanical wonder has been instrumental in shaping air travel. In turn, this opened additional windows in the industry. The development of the Wasp is one of the most significant steps in aviation history, yet the process was so troubled it's a wonder it happened at all. This is the story of how the Wasp was developed, what it meant for the industry, and the sheer size of its legacy.

Frederick Rentschler was central to the creation of the Wasp engine. With the U.S. Army Signal Corps in World War I, he had worked closely with Wright-Martin's Hispano-Suiza engines, also serving as the president of Wright. He parted ways with the company when it proved reluctant to innovate with its approach to new engine technologies.

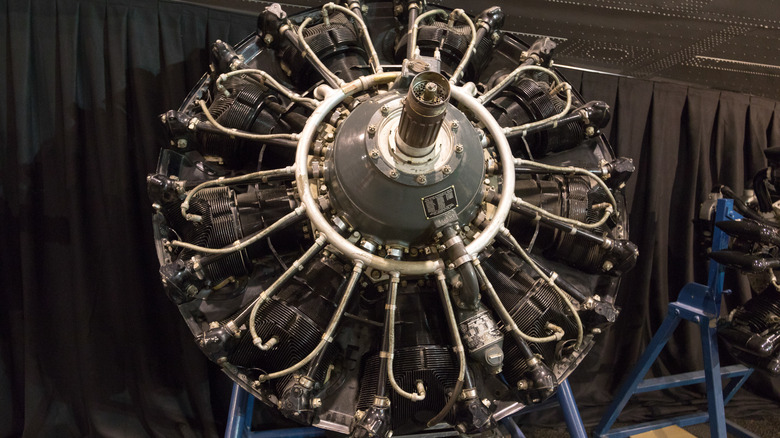

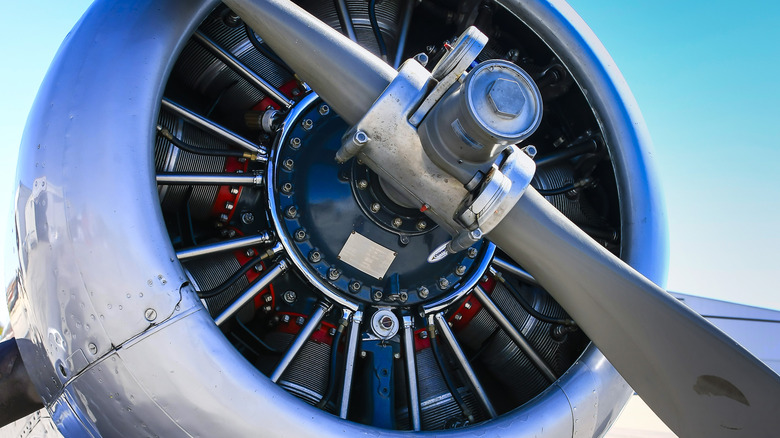

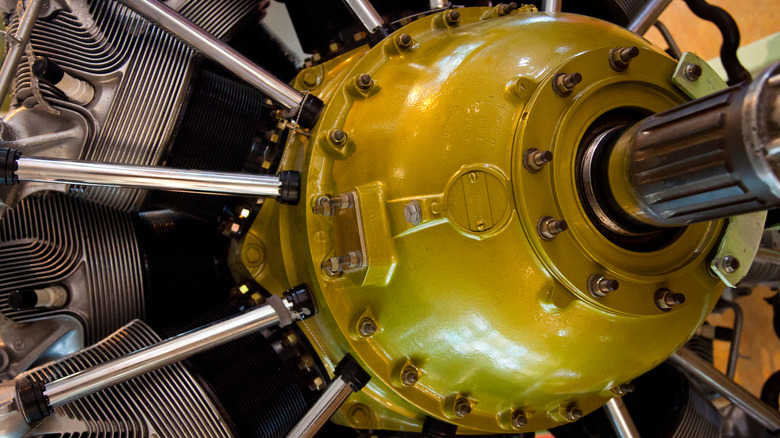

A radial engine, Rentschler determined, would be much lighter than the hefty ones that were widely used. An air-cooling system, rather than a liquid-cooling one, could be the key to improved performance. The end result of this line of thinking was the remarkable Wasp.

When was the first Wasp engine developed?

Rentschler's goal was to increase capacity without letting the engine size become detrimental. If successful, this could boost efficiency and the practicality of flight. The idea had huge potential, and on receiving a total of $1,250,000 in funding for the project from investors, Rentschler collaborated with Pratt & Whitney, then a tool-making company, for additional capital and a manufacturing space equipped to create his prototype engines.

In 1925, he founded Pratt & Whitney Aircraft Company, based in Connecticut. He was joined, thanks to his prior experience in the industry, by some highly accomplished engineers: Andy Willgoos, Earl A. Ryder, and John Borrup were among their small but talented ranks. In short order, they had created the world's very first Wasp engine, Wasp Serial Number 1 making its debut Christmas Eve in 1925. Its impact and legacy would prove remarkable.

One particularly large early investor in the Wasp engine was the U.S. Navy, which was in need of such an engine because radial, air-cooled technology had several key qualities: lighter, potentially faster and more powerful planes. One day, such aircraft would be capable of making safe landings on aircraft carriers. The Navy was so impressed with the Wasp that it placed 200 engine orders.

The legacy of the Wasp engine family

Radial engines weren't new (the Wright R-790 Whirlwind had already seen use), but this was an evolution. Named for the buzzing sound it emitted, the Wasp was a smoothly-operating engine enhanced over time with adjustments like replacing duralumin components with steel.

The first iteration of the Wasp, the R-1340, was produced until 1960. By then, it had become the stuff of legend: 1945 saw the production of 300,000 of the engines, an enormous part of the Allied effort during World War II.

In 2016, the original Wasp engine was officially declared an historic engineering landmark by The American Society of Mechanical Engineers. In response, the Hartford Business Journal reports, Pratt & Whitney Engineering Vice President Tom Prete said that the honor was "a tribute to the small group of visionaries who built it and set the standard for Pratt & Whitney's dependable engines."

Pratt & Whitney reports that 85,000 of its engines are in service around the world now. Much of this is due to the Wasp's success, just like the company's later JT3.