10 NASA Inventions Still Used Today

We may receive a commission on purchases made from links.

The National Aeronautics and Space Administration was established in 1958, an evolution of the National Advisory Committee for Aeronautics, which was made by the U.S. Congress way back in 1915. While it was, at least in part, a reaction to the Soviet Union's launching of Sputnik in 1957, NASA went on to establish itself in the scientific community as a research and development powerhouse, exploring space and putting an American on the Moon just 11 years after the agency's creation.

NASA's place in history includes inventions used in space travel that have been transformed into useful tools and products for everyday life, often through the NASA Technology Transfer Program, or NTTP. The Transfer Program includes free computer programs and links on how businesses can license NASA tech for commercial use.

Tech transfer is an important part of NASA's mission, and the agency's decades-old Spinoff magazine is an annual publication that features space technology that has been adapted to benefit folks back on Earth. Hundreds of products got their start or were vastly improved as part of NASA's ongoing exploratory missions to the stars. What follows is a small selection of those innovations, all of which are still used today.

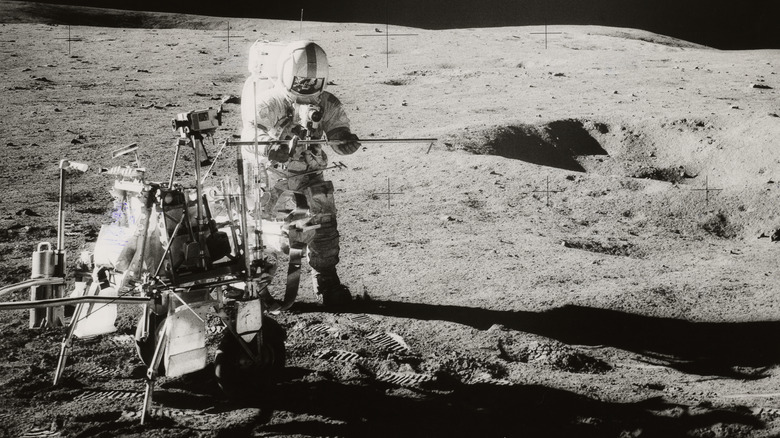

Cordless tools

When the Apollo program was announced in 1961, dozens of projects were launched to address the problems inherent in performing everyday tasks — like vehicle maintenance, for example — in space. Toolmaker Black + Decker collaborated with NASA to create a cordless zero-impact wrench that would turn bolts without spinning the user in zero gravity. As the patent owner for a portable electric drill from 1917, Black + Decker was uniquely suited for another collaboration with NASA as well.

During the Apollo 15, 16, and 17 missions, the collection of samples of lunar rock and soil also required specialized tools. While samples could be collected from the moon's surface, subsurface samples were also needed. For the collection of those samples, a drill was required, and like everything on any space mission, it needed to be lightweight and compact in size. Portability, as well as an onboard power source, were also necessary traits. Black + Decker worked with NASA to build a drill that met all those requirements and could extract samples from as deep as 10 feet below the lunar surface.

The immortal Dust Buster was also born from this research, using what Black + Decker learned in the development of the portable drills' motor design and low power consumption.

Cell phone cameras

Spacecraft imaging has long been a challenge, but the advent of digital photography has helped remove many of the roadblocks scientists initially faced. NASA used something called charge-coupled device imaging in the 1980s, which formed the foundation of digital cameras. The CCD tech was improved upon by engineer Eric Fossum, who worked at NASA's Jet Propulsion Lab out of Pasadena, California. Fossum was considered an expert in CCD systems, and his work to improve the high power consumption and higher-still charge-transfer efficiency led to an entirely new imaging tech.

The new technology, called a Complementary Metal Oxide Semiconductor (CMOS) image sensor, was licensed by Kodak, Intel, and AT&T. Fossum and several colleagues also ended up licensing the tech and left NASA to form their own company, Photobit, to further develop and improve CMOS tech. CMOS sensors ended up in DSLR cameras, dental X-rays, and GoPros, but cell phones are where the tiny photography tech really took off. Much like in space exploration, cell phone manufacturers demanded small camera sizes and low power consumption, two things CMOS sensors already had going for them.

Emergency blankets

The moon is cold, harsh, and uninviting. Among the many, many reasons we're not already living in little colonies up there is the temperature, which can reach 250 degrees Fahrenheit during the day and -208 at night. Temperatures like that require an incredible amount of adaptivity and insulation, not only for the people working in those environments but also for their equipment.

Aluminized mylar sheeting, the shiny foil we see on a lot of space vehicles and suits, is incredibly thin and lightweight, making it ideal for space travel. Its shiny side reflects heat or traps it inside, and the sheets can be used for insulation as well.

Here on Earth, runners and hikers often use blankets made of this material due to their lightweight, incredible heat retention, and small footprint when folded. The thin metal-coated plastic sheet traps body heat while also blocking wind from cooling the skin's surface, basically keeping a person warm with the heat one's body is actively shedding.

For outdoor activities, the reflective sheet doubles as a signaling tool if a camper or hiker becomes lost in the wilderness. These blankets are also commonly included in EMT, travel, and wilderness emergency kits due to their ability to keep people warm while also taking up very little room and adding very little weight.

Improved tires and roads

Those same harsh lunar conditions that inspired the last entry had to be overcome for the tires NASA installed on its portable workbench, lovingly called the "Rickshaw," on the Apollo 14 mission. In the '60s and '70s, tires designed for summer use would lose traction and flexibility in the winter. Goodyear Tire worked with NASA to develop a tire that would remain pliable and durable in cold temperatures like those faced on the moon. The result was a tire made of a rubber that remained pliable at temperatures as low as -195 degrees Fahrenheit. Goodyear used what it learned in the creation of those lunar workbench tires to create studless winter tires for use here on Earth.

Landing a space shuttle provides its own host of problems. One solution was the installation of grooved runways to minimize hydroplaning. Grooving was a practice developed at NASA's Langley Research Center and tested alongside the Federal Aviation Administration. That technique was adopted in road and runway construction to help more efficiently remove water from the driving surface.

Additionally, TPMS sensors, the tire pressure sensors that are now required in all passenger vehicles in the United States, are a direct result of a full NASA redesign of its space shuttle tires. That redesign was prompted by the concern that a low shuttle tire could result in a pair of blowouts if tire pressures weren't constantly monitored.

LEDs

The benefits of gardening in space are numerous: providing a food source and a pastime activity in gardening, and even improving air quality in a spaceship. When NASA looked into the lighting systems necessary to keep plants alive in space, lightweight and low power consumption were important, but several other factors needed to be considered as well.

Replacement bulbs take up space, and various sizes might be required for different use cases. Heat output needed to be minimized. The ability to withstand brutal temperatures and produce different colors of light was valuable. Lastly, a shatterproof bulb was crucial as well — imagine trying to use a broom and dustpan in a zero-gravity environment!

LED technology was seen as the answer to all these problems. NASA got to work, producing a prototype solid-state LED lighting module. The unit met the many requirements of space travel and included the ability to be controlled remotely, allowing ground control to adjust and monitor the needs of plants and people aboard space vehicles. By 2008, a full LED system was installed in the International Space Station.

The lighting also proved beneficial to astronauts. During the development of the lighting unit for plants, another NASA-funded group of researchers learned that certain colors of light aided astronauts' sleep cycles. Circadian rhythms were being affected by the multiple sunrises and sunsets space travelers see in a 24-hour period, and the ability to assist those people by adjusting light levels and colors was a fantastic added benefit in the adoption of LED lighting systems.

Wireless headsets

When a commercial airline pilot recruited a friend to help him develop a lightweight headset to replace the uncomfortable, heavy communications devices common in the '50s and '60s, the pair developed a system that ended up being adopted by United Airlines and formed the company Plantronics.

Around that time, NASA experienced a terrifying scenario — the agency lost contact with an astronaut during the recovery phase of its 1961 Mercury-Redstone 4 mission. While that astronaut was recovered, the very real possibility of his death made NASA reconsider its communications systems, and the company it used happened to employ a Plantronics headset in its radio transceiver.

That headset prompted a different astronaut to ask if Plantronics could install a headset into his helmet. Plantronics was successful in doing so, and its collaboration with NASA led to years of improved designs and communications across multiple off-Earth missions.

Plantronics has gone on to win awards for its Bluetooth headsets and develop hands-free systems for businesses, homes, first responders, and even gaming applications, having developed an official headset for the original Xbox.

Solar cells

Solar power has always been at the forefront of NASA's electricity considerations; after all, what better source of power is available in space? The collection and storage of solar energy have been improved immensely over the years, and NASA's research has contributed to many of those technological advancements.

While NASA didn't invent the solar cell — credit to that goes to a trio of Bell Laboratory scientists in 1954 — the need to create and store power in space has led the agency to innovate and improve upon the technology dozens of times over and with good reason. The International Space Station, for example, has eight 114-foot solar array "wings," each holding about 33,000 solar cells. For all that mass, only around 14 percent of the sunlight that hits those panels is converted into usable energy. However, that tech is several years old.

Solar cells today can be made cheaper, thinner, and even into flexible sheets that can harness up to 90% of the sunlight they are exposed to — you can even purchase a version of this tech to charge your phone while hiking for around $20. And as researchers learn more, solar technology continues to break new ground.

Other improvements developed by NASA's scientists, in collaboration with outside assistance, are constantly making solar panels more efficient. These developments include nanotube technology that further reduces reflected light while also increasing the surface area of solar panels, adding even more potential for energy collection. Another enhancement was the creation of a self-cleaning solar panel that uses an electrical charge to clear efficiency-reducing dust from the surface of the panel itself.

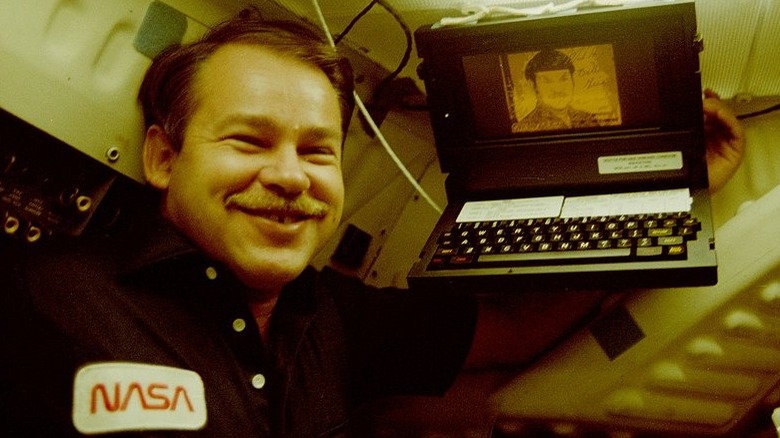

Portable computers

Another invention NASA built upon and popularized, the portable computer, was an early '80s idea that was adapted for use in space. At a starting price of over $8,000, the GRiD Compass was not exactly accessible to the everyday '80s tech enthusiast, but it caught the attention of NASA for several reasons. Its plasma screen made the Compass lighter than its competition, all of whom used heavier CRT screens.

Its use of solid-state "bubble memory" was also appealing, as it had no moving parts and was more durable than a hard drive. Speaking of durability, the GRiD computer offset the heat produced by that bubble memory with a casing made of a magnesium alloy, giving the machine a more rugged look and feel than plastic casings. In fact, the GRiD that was aboard the Challenger is said to have survived that shuttle's tragic 1986 crash.

To get the Compass into space, the modifications NASA was required to make were surprisingly minimal — a new power cord compatible with the space shuttle was installed, and a fan-based cooling system was employed. Software is where NASA really got to improve on the metal-cased beast and turn it into a portable powerhouse.

When the modified GRiD, now dubbed the Shuttle Portable On-board Computer (SPOC), went into space aboard the Columbia in 1983, it featured graphics-based positioning software that was used to plot out photo opportunities, and a backup reentry program was installed as a failsafe. The SPOC remained a regular passenger on shuttle missions into the 1990s.

[Featured image by NASA via Wikimedia Commons | Cropped and scaled | Public Domain]

Joysticks

When designing the Apollo lunar rover, the need to control a vehicle while in a spacesuit required a bit of innovation on NASA's part, leading to the installation of a one-handed stick that controlled steering, braking, and acceleration. While NASA didn't invent the joystick, its innovations in design are seen in everything from video game controls to systems that allow differently-abled drivers to control vehicles without a steering wheel.

While input devices have evolved quite a bit since the heyday of NASA, the humble joystick has remained an integral part of modern gaming console controllers and space suits themselves. In fact, smaller sticks are used as part of an astronauts' SAFER system, a kind of last-resort jetpack used as a failsafe if tethers were to fail during a spacewalk. One astronaut-turned-entrepreneur used his experience in both space and medicine to design a more streamlined controller for drones, with the hopes of using that same tech to improve robotic surgery control options.

Interestingly, scientists at NASA's Jet Propulsion Lab have considered using modern video game controllers to interact with several different robots, citing that the gamepads are durable and easy to use. Given NASA's history of collaboration with other businesses, it's a very real possibility that we'll see an Xbox or PlayStation controller in the hands of astronauts in the near future.

Memory foam

A difficulty one might not think about when visualizing the many, many problems involved in putting a manned crew into space is seating. There is an incredible amount of pressure and shock that needs to be absorbed by a chair holding a person as they jet off into the vast darkness of space. Fortunately, NASA was able to develop a solution, one that the agency considers its most well-known and widely used spinoff ever.

Temper foam was created in 1966 when aeronautical engineer Charles Yost was contracted by NASA. Yost had worked with NASA previously to design recovery equipment for the Apollo program and was now asked to improve the design of airplane seating for protection against both crashes and intense takeoff vibration in the space shuttle program. The engineer's response was the creation of an open-cell polymeric "memory foam" that absorbed energy while also maintaining softness.

Yost went on to create the company Dynamic Systems, a company that would improve that technology and diversify it for dozens of uses after selling its initial rights to the tech. While the Tempur-Pedic mattress and pillow are the most popular use of this memory foam, other uses include motorcycle seating, medical cushioning, prosthetic limbs, crash helmets, and archery targets.