Scientists Are Planning To Melt Roads On The Moon Using Lasers - Here's How

One of the biggest challenges in establishing a habitat on the moon, Mars, or any other body in the solar system is the need for critical infrastructure before dreams of human settlement can come to life. It's a monumental task to carry all the raw materials and required machinery to the moon, but even if that is made possible by massive vehicles like SpaceX's Starship in the near future, we would need roads for ferrying it all across the lunar surface and avoiding the hazards created by mobile moondust.

But that moondust can be turned into the solution itself. After all, scientists have emphasized that extra-Earth habitats will rely on local resource utilization. Experts at Germany's Aalen University, BAM Institute of Materials Research and Testing, Clausthal University of Technology, and the German Aerospace Center are working with Austria's LIQUIFER Systems Group on an idea that involves melting that lunar dust to make solid material for roads.

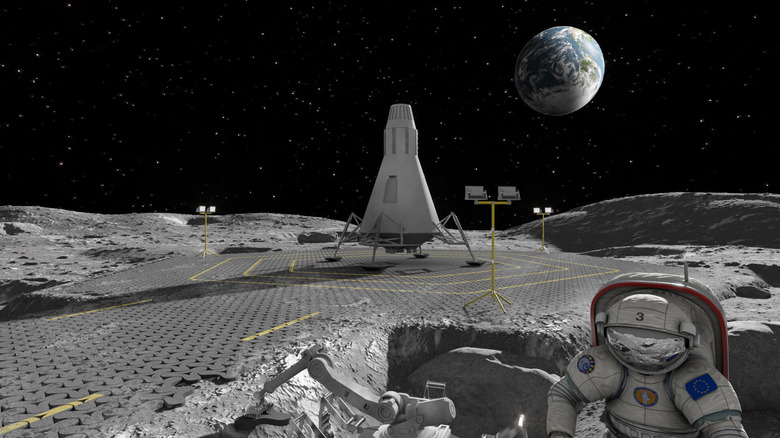

To put it more specifically, the team seeks to melt the surface regolith to create thin blocks with a specific shape that can be used to design interlocking pieces for roads and landing pads. The inspiration behind the tests was 'PAVER' (Paving the road for large area sintering of regolith), which is backed by the European Space Agency. It envisioned using a large lens to concentrate sunlight and use the energized beam to melt the material to make solid pieces.

How it all works

To recreate the effect of using a lens for concentrating sunlight, scientists behind this experiment used a 12-kilowatt carbon dioxide laser on a material mimicking the dusty lunar surface. The immense heat produced by the laser beam melted the raw material and turned it into a glassy or crystalline solid. The strength of the material was found to be close to that of concrete. When it comes to applying the technique on the moon, the team hopes to replicate the laser's energy using a Fresnel lens to be carried to the moon in the near future.

The lens, which needs to measure 2.37 square meters across to achieve the desired power, would act as a sunlight concentrator to create an energy beam with a 45mm diameter and a material thickness target of 15-20 millimeters, according to the study. In the long run, the team hopes to use the laser-sintered moondust to make solid 3D structures such as habitats for astronomers, hangars, and storage units.

Scientists are hoping that structures made from this material will also shield the habitats from micrometeorites and harmful radiation, which is extremely important because the moon lacks an atmosphere that can block it. Carrying powerful laser equipment necessary for making crystalline blocks to the moon isn't feasible, but a lens that doubles as a light concentrator would be far easier, and it also solves a multitude of problems, including energy generation and supply requirements.

Long road ahead

During the tests, the team managed to create hollow-centered geometric shapes of roughly 2.5 meters that can be interlocked to create a solid surface for landing sites or paths. As promising as it all sounds, and assuming it's possible to put a sunlight-concentrating lens on the moon in the immediate future, the process of building the necessary road infrastructure could take years. "The team estimates a 100 sq. m landing pad with a thickness of 2 cm of dense material might be constructed in 115 days," says an ESA press release.

This won't be the first project of its kind, however. As part of another ESA-supported project, a team 3D-printed bricks made out of material similar to moondust using concentrated sunlight. The charred bricks created as part of the tests had a material strength similar to that of Gypsum, which is used in plaster, tiles, and cement as a building material. The moon itself is no stranger to the phenomenon. There is an abundance of glassy beads in the lunar soil, which are said to have formed under extreme conditions of temperature and pressure resulting from an impact event.

The biggest benefit of making solid roads using lunar regolith is that it solves the problem of moondust, which not only damages vehicles and other equipment but also poses a danger to spacesuits. But given its natural availability as a raw material, the latest approach also solves the logistics headache and saves billions of dollars.